Flexible Pallet Labeling

Real-time Pallet Marking Systems for coding, marking, and labeling pallets on 1, 2, or 3 sides.

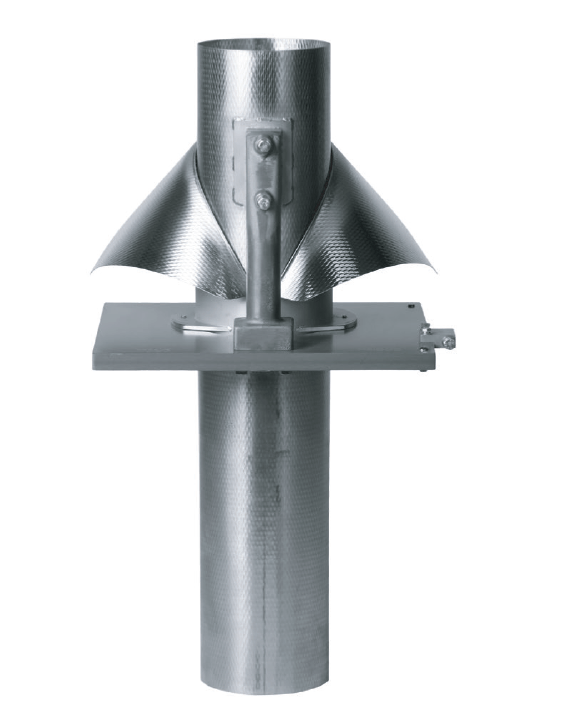

Pallet Marking | APL 8000 Series

The UBS APL 8000 ELV Series is designed to print and apply labels in real time on double-stacked pallets or pallets with variable heights.

Double-stacked pallets include two pallets, usually measuring 800×1,200mm or 1,000×1,200mm.

Half double-stacked pallets consist of 2 sets of 2 half pallets, measuring 800x600mm or 1,000x600mm. Alternatively, three sets of 3 half pallets measuring 800x600mm or 1,000x600mm.

Pallets with variable heights refer to pallets with different heights.

| Technical Data | APL38S Series |

|---|---|

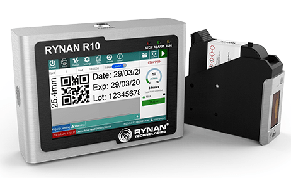

| PRINT ENGINE | ZEBRA, DATAMAX, SATO… |

| PRINTING RESOLUTION | From 206 up to 300 dpi |

| LABEL ROLL | Max. diameter.: up to 300 mm / 11.8” |

| RIBBON ROLL | Max. Length: 600 m / 1.968 ft (depending on print engine specifications) |

| INTERFACE | RS232, USB, Ethernet, Wireless (optional) |

| DISPLAY | Touchscreen display 5,7″ |

| WEIGHT | Approx 850,8Kg |

| DIMENSIONS | Width: 2789 mm /109.8” – Depth: 1405 mm / 55.3” Height: 1230mm / 48.2” |

| POWER SUPPLY | 110 / 220 VAC, 50 / 60 Hz |

| WORKING TEMPERATURE | From +4°C / 39.2 F up to 45°C / 113 F From +4°C / 39.2 F up to 70°C / 158 F (Optional Cooling System) |

| HUMIDITY | Between 20-85% non-condensing |

Contact us today for the best pallet coding solution for your tertiary packaging.