Automation

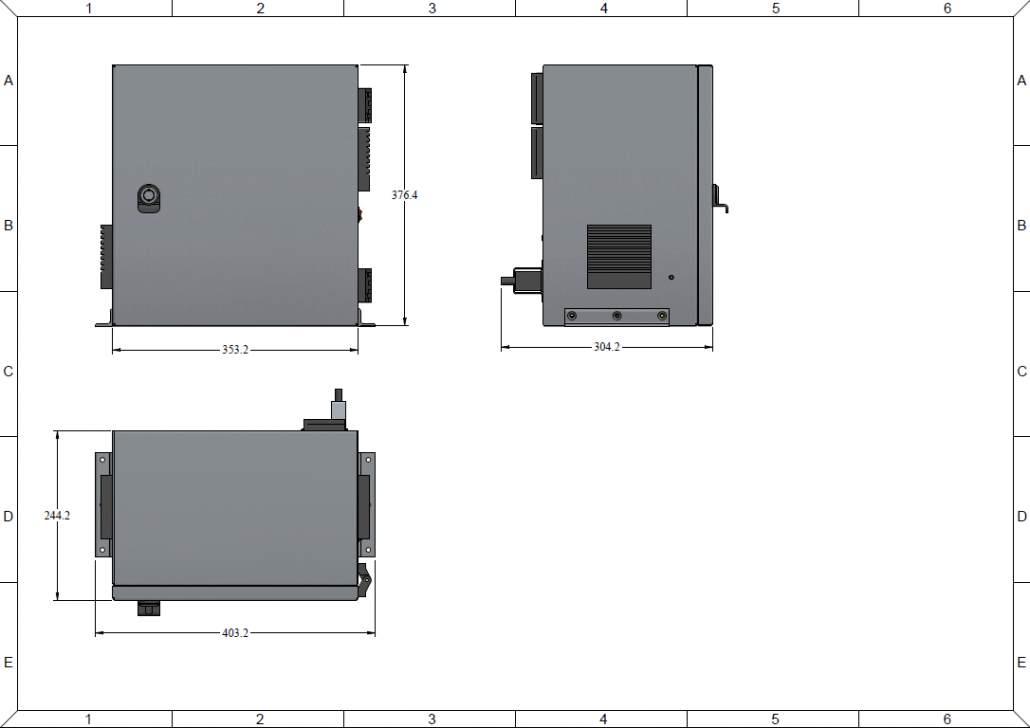

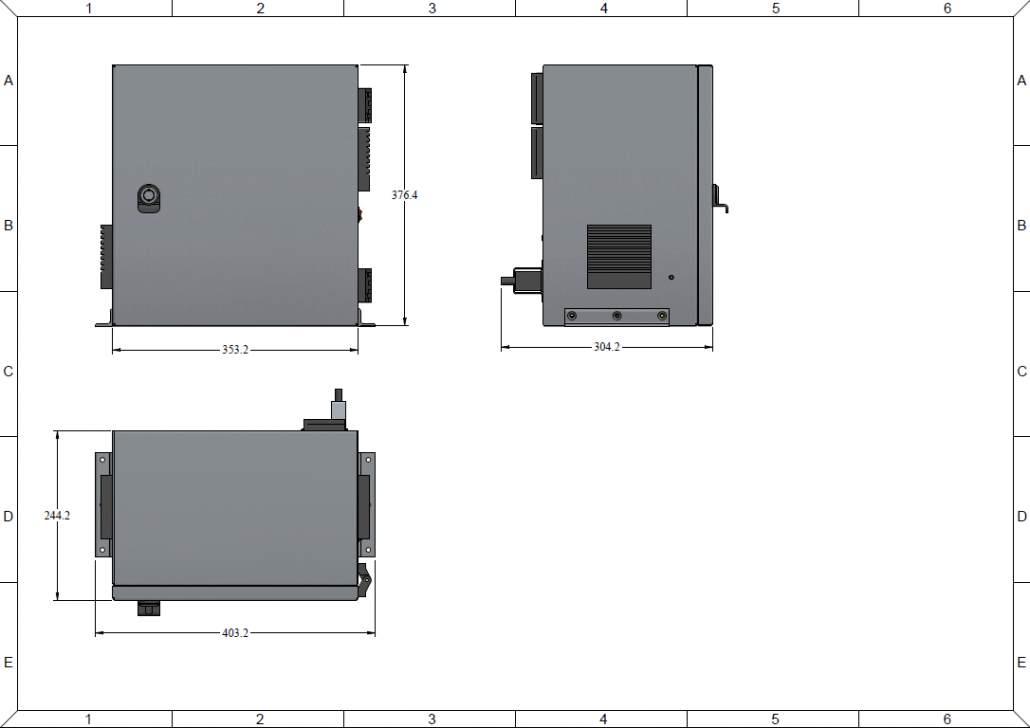

with Electrical/Electronic Panel

The Control System with an Electrical/Electronic Panel is a customized control box for controlling existing conveyors.

Uptime Advantage

Compact design for mounting under the conveyor system with required I/O control.

Features

- PLC Based Logic Control

- MS Body with Powder coated.

- Electrical panel design as per Industrial Standards

- Bi-directional air cooling

- Multiple Input/Output controls

- Electrical panel design as per Industrial Standards

- Designed to withstand tough production line environments.

- Wall/floor mounting designed.

| Parameter | description |

|---|---|

| Control System with Electrical/Electronic Panel | • PLC-based Controller • Electrical Standard wiringable high-resolution lens with minimum distortion is provided based on camera model. |

| Embedded I/O controller with embedded software | • I/O Controller – Processing and controlling hardware signal and communicating with software; this controller integrates with sensor electrical/electronic parts. • I/O Communication |

| Material of Construction | • Covers – SS304 |

| External communications | • RS232, Ethernet, USB |

| Operating temperature | • 5°-40°C |

| Power supply | • 230 Volt AC, single phase with MCB for protection |

The Product Diverting Station is a customized system designed to scan 1D/2D code, divert it to different conveyors, and apply 2D code labels on pre-defined product boxes.

Features

- Plug & Play System

- User-friendly Operation Panel

- Auto triggering system

- User-friendly Operating Panel & intuitive Menu Navigation

- Customized Illumination for glossy surfaces

- Ergonomic design as per Industrial Standards

- Robust 1D / 2D code algorithm to decode multiple codes in a single scan.

- Variable Speed Belt Conveyor with adjustable Side guide rod.

- Multiple High-resolution cameras suitable for decoding even 8 x 8 mm 2D codes for larger scan area

- State-of-the-art reflection-free illumination ensures multiple 1D / 2D code decoding over glossy surfaces.

- Designed to withstand tough production line environments.

- Improving production line up-time

- Quick product changeover

| Parameter | description |

|---|---|

| Product Diverting Station | • Camera - High resolution camera for 1D/2D/QR code scanning • Lens – A suitable high-resolution lens with minimum distortion is provided based on camera model. • Illumination - White LED, reflection free homogeneous illumination for reflective surface (inside plastic scanning) • Simultaneous scanning of diverted products for verification • Sensors (as applicable) • Ejector - Pneumatic pusher with rejection bin • Print and apply to label unit camera to inspect label 1D/2D/QR code • Traffic management system for jamming bundles |

| PC | • Processor Group - Intel Chipset High speed controller, above 2.2 GHz • Operating System – Windows 10 Pro • Memory Capacity - 4 GB • Storage Capacity - 120 GB SSD • Display Size – 15” or 17” • Operator interface – LED/LCD and touch screen |

| Embedded I/O controller with embedded software | • Camera - High resolution camera for 1D/2D/QR code scanning • Lens – A suitable high-resolution lens with minimum distortion is provided based on the camera model. • Illumination - White LED, reflection-free homogeneous illumination for reflective surface (inside plastic scanning) • Simultaneous scanning of diverted products for verification • Sensors (as applicable) • Ejector - Pneumatic pusher with rejection bin • Print and apply to label unit camera to inspect label 1D/2D/QR code • Traffic management system for jamming bundles |

| Material of Construction | • Section frame, Structure, Plates – Aluminium • Covers – SS304 |

| External communications | • RS232, Ethernet, USB |

| Operating temperature | • 5°-40°C |

| Power supply | • 230 Volt AC, single phase with MCB for protection |

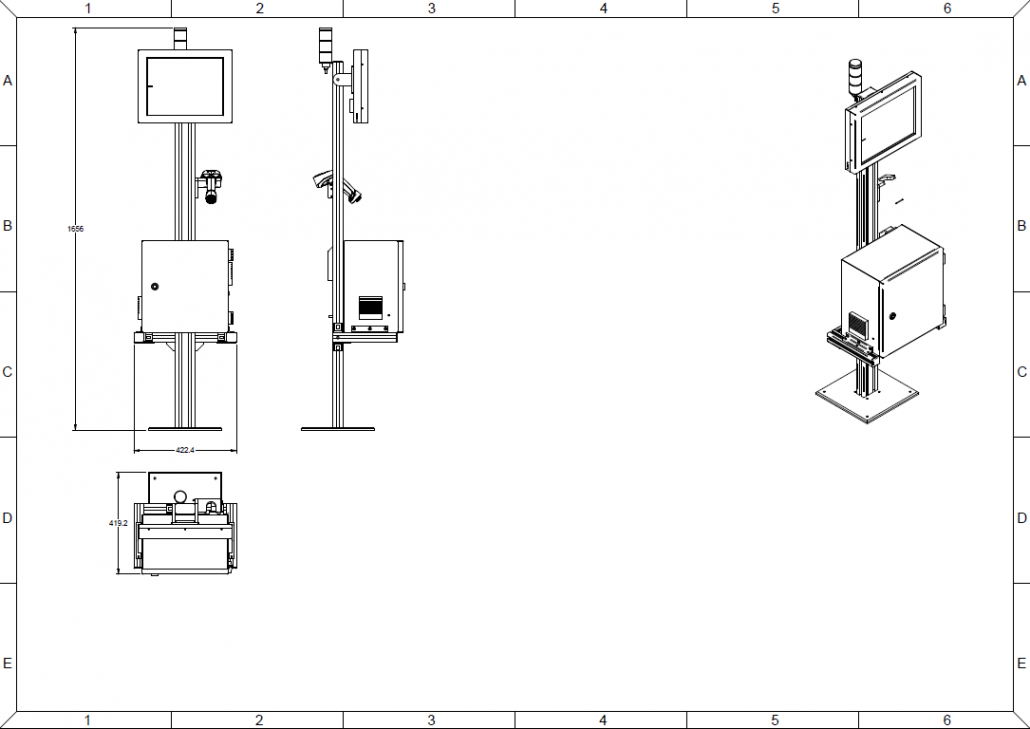

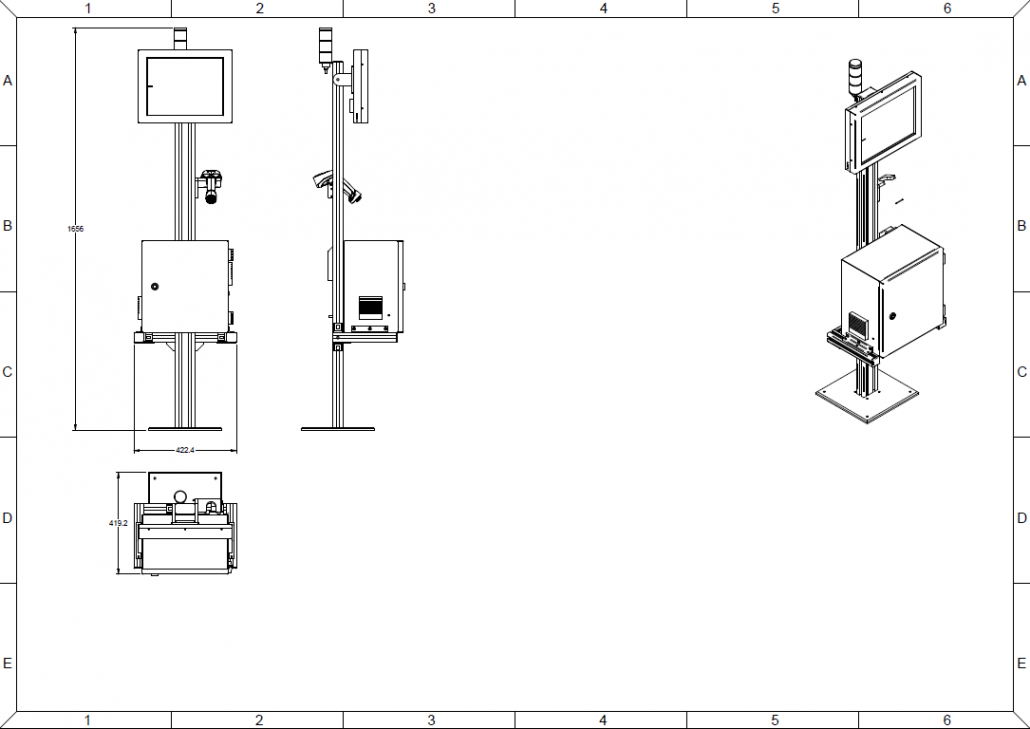

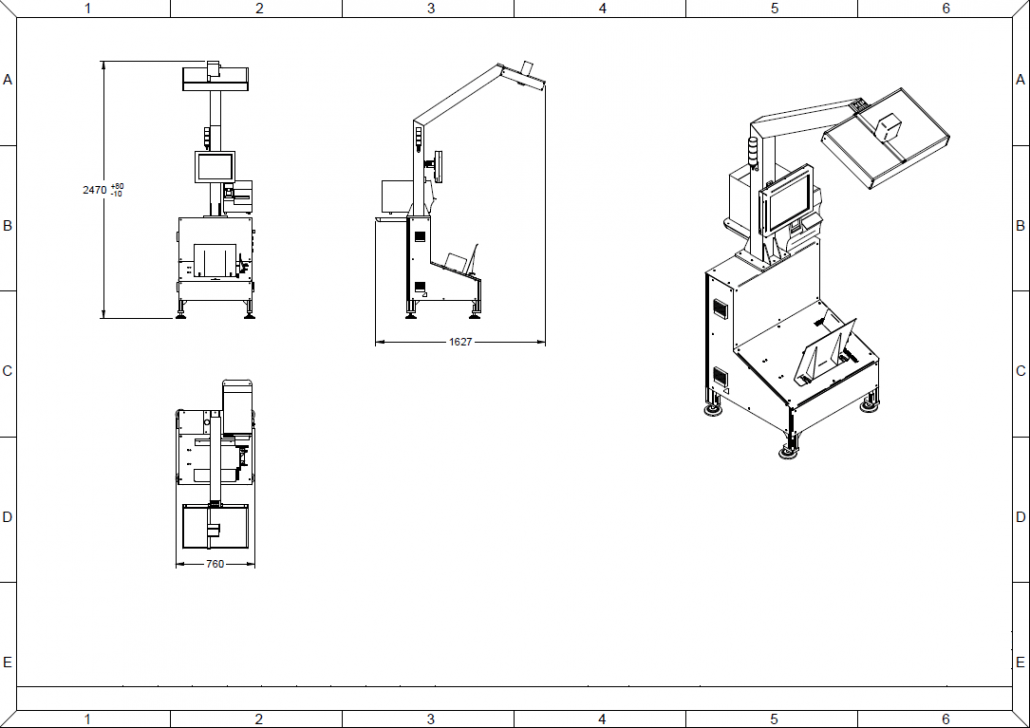

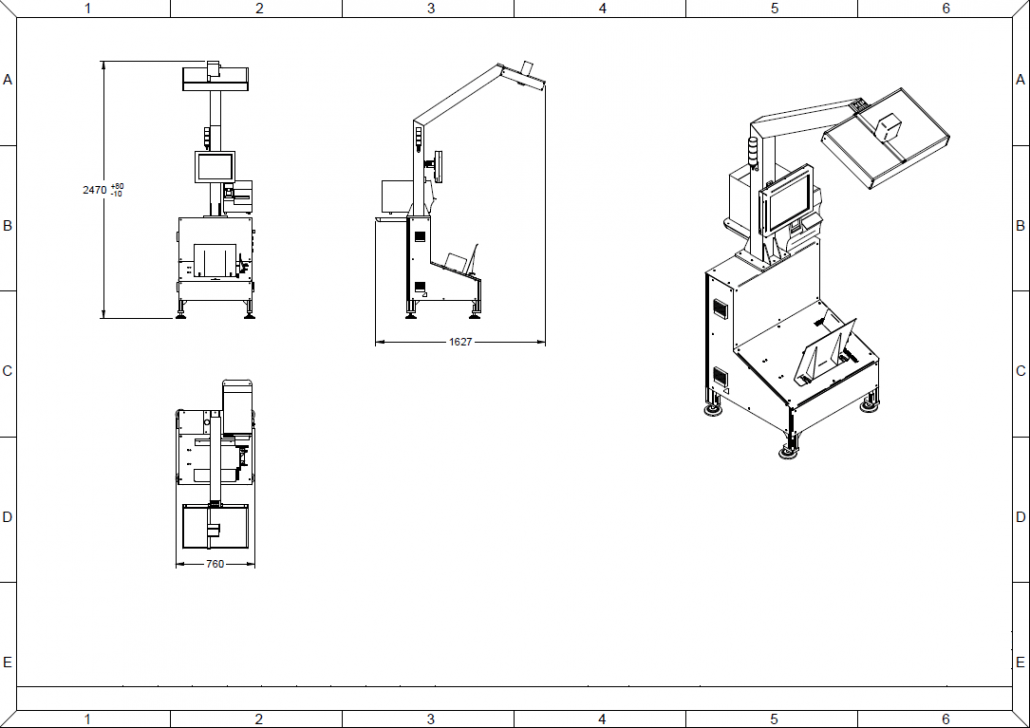

The Manual Scanning Machine is a customized scanning system mounted on an existing camera system, designed to scan pre-printed codes present on the box for verification and validation with the Database.

Uptime Advantage

Simple and Easy interface software for existing camera system, no intermediate or third-party software integration required.

Features

- Connect with Multiple Camera Systems

- PLC-based triggering system.

- User-friendly Operating Panel & intuitive Menu Navigation

- Quick product changeover

- Inbuilt Database facility for quick data processing

- Ergonomic design as per Industrial Standards

- Floor mounting stand for quick installation

- Designed to withstand tough production line environments.

- Improving production line up-time

- Interlock facility for existing conveyor system

- Wi-Fi handheld scanner for manual scanning option

| Parameter | description |

|---|---|

| Manual Scanning Machine | • I/O Controller – Processing and controlling hardware signal and communicating with software; this controller integrates with sensor electrical/electronic parts. • Camera communication • I/O Communication • Solid State Relay card • Required cables |

| PC | • I/O Controller – Processing and controlling hardware signal and communicating with software; this controller integrates with sensor, electrical/electronic parts. • Camera communication • I/O Communication • Solid State Relay card • Required cables |

| Embedded I/O controller with embedded software | • Processor Group - Intel Chipset High-speed controller, above 2.2 GHz • Operating System – Windows 10 Pro • Memory Capacity - 4 GB • Storage Capacity - 120 GB SSD • Display Size – 15” or 17” • Operator interface – LED/LCD and touch screen |

| Material of Construction | • Section frame, Structure, Plates – Aluminium • Covers – SS304 |

| External communications | • RS232, Ethernet, USB |

| Operating temperature | • 5°-40°C |

| Power supply | • 230 Volt AC, single phase with MCB for protection |

The Multi Scanning Machine is a customized scanning system designed to scan multiple pre-printed codes at the top of the box. It is available in two variants.

It is a top-side camera-based system with variable depth of field. As well as it's suitable for manual standing operations.

Uptime Advantage

No camera adjustment is required to scan codes at various heights.

Features

- Auto triggering system

- User-friendly Operating Panel & intuitive Menu Navigation

- Customized Illumination for glossy surfaces

- Ergonomic design as per Industrial Standards

- Robust 1D / 2D code algorithm to decode multiple codes in a single scan.

- Auto triggering along with manual trigger option.

- High-resolution camera (20 Megapixels) suitable for decoding even 8 x 8 mm 2D codes

- State-of-the-art reflection-free illumination ensures multiple 1D / 2D code decoding over glossy surfaces.

- Designed to withstand tough production line environments.

- Improving production line up-time

- Quick product changeover

- Adjustable guides for variable packing size to ensure the correct positioning of the product.

| Parameter | description |

|---|---|

| Automatic Scanning Machine | • Operator interface – LED/LCD and touchscreen • Camera - High-resolution camera to scan or inspect the printed 2D Code. • Lens – A suitable high-resolution lens with minimum distortion is provided based on the camera model. • Illumination - White LED, reflection-free homogeneous illumination • Sensor - Limit Switch • Audible and visual alarm • Maximum Scanning Area (L x W x H) – 300mm X 200mm X 150mm |

| PC | • Processor Group - Intel Chipset High-speed controller, above 2.2 GHz • Operating System – Windows 10 Pro • Memory Capacity - 4 GB • Storage Capacity - 120 GB SSD • Display Size – 15” or 17” |

| Embedded I/O controller with embedded software | • I/O Controller – Processing and controlling hardware signal and communicating with software, this controller integrates with sensor, and electrical/electronic parts. • Camera communication • I/O Communication |

| Material of Construction | • Section frame, Structure, Plates – Aluminium • Covers – SS304/MS |

| External communications | • RS232, Ethernet, USB |

| Operating temperature | • 5°-40°C |

| Power supply | • 230 Volt AC, single phase with MCB for protection |

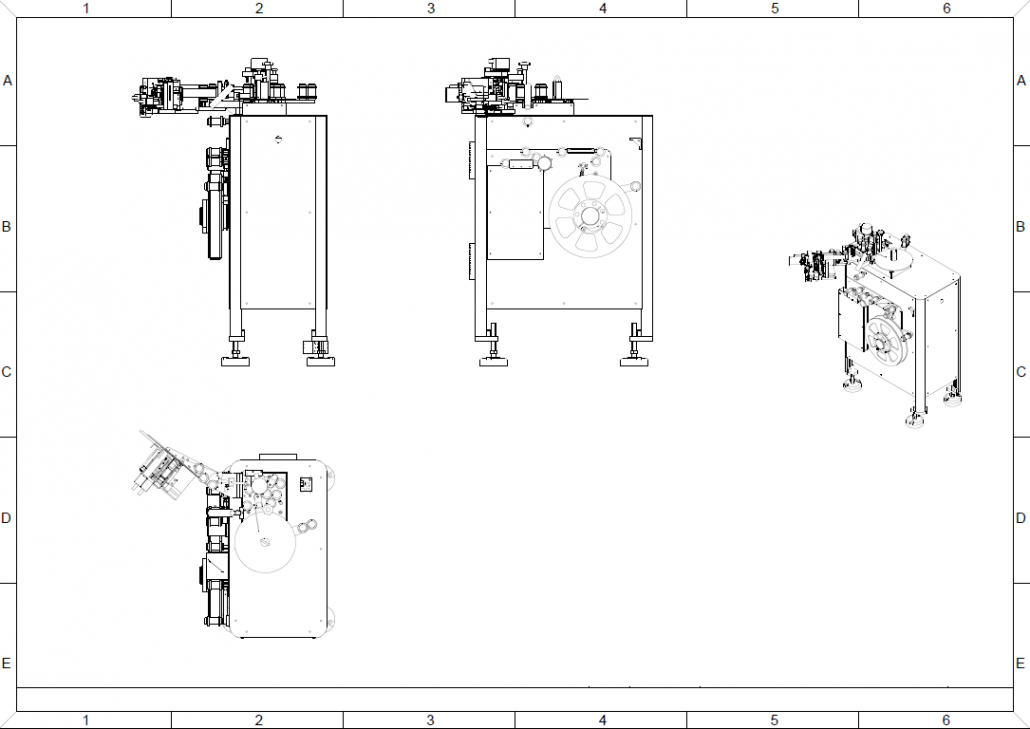

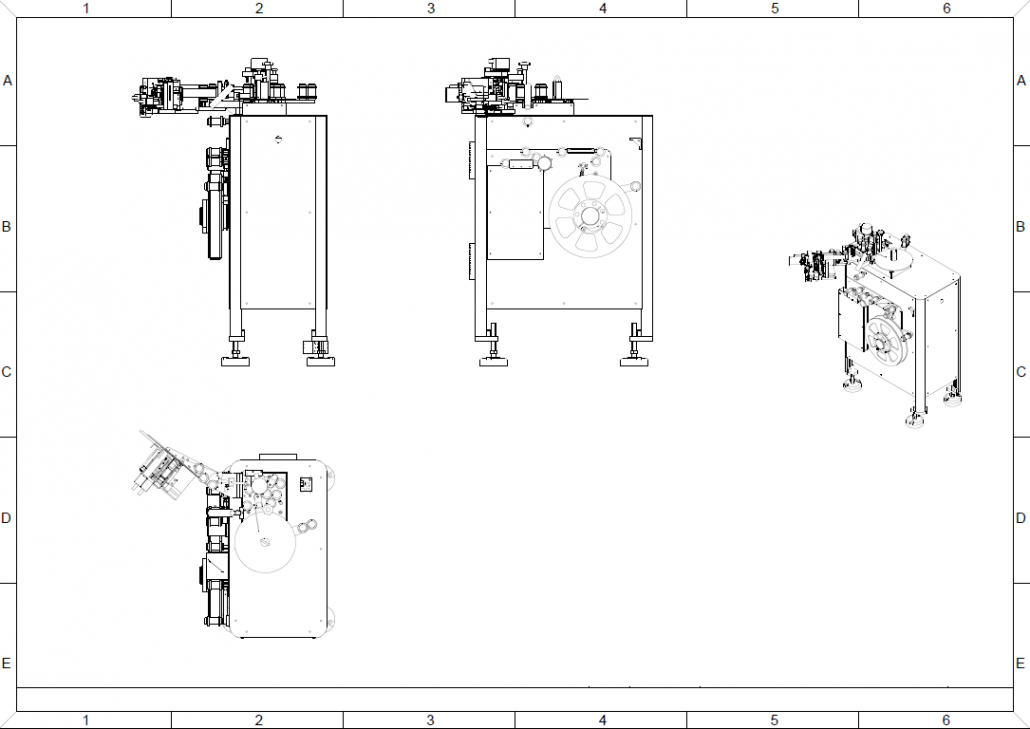

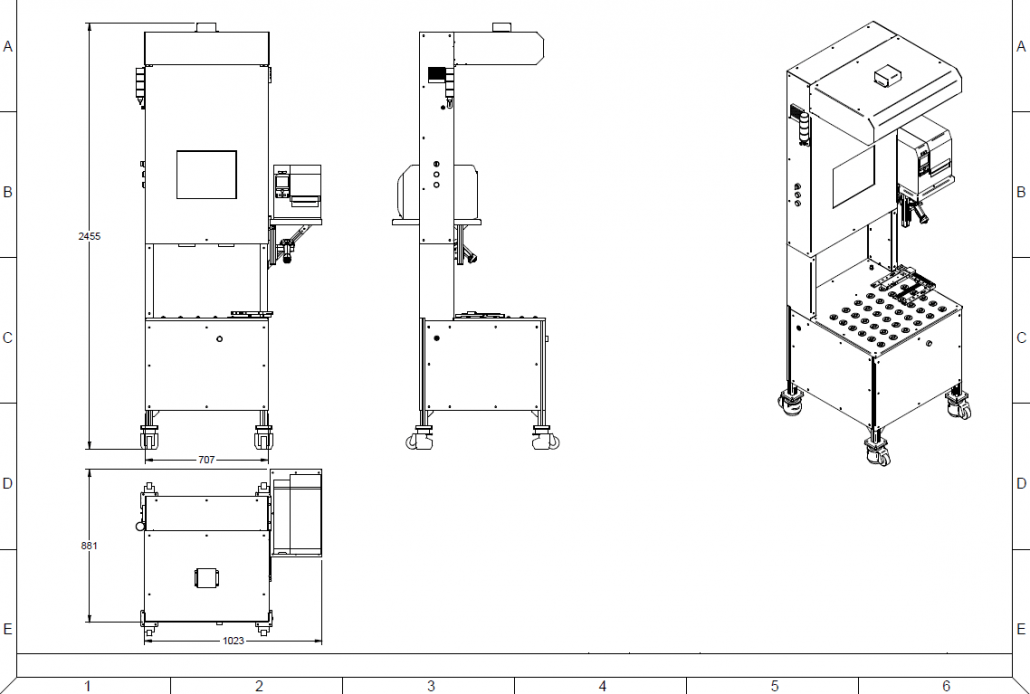

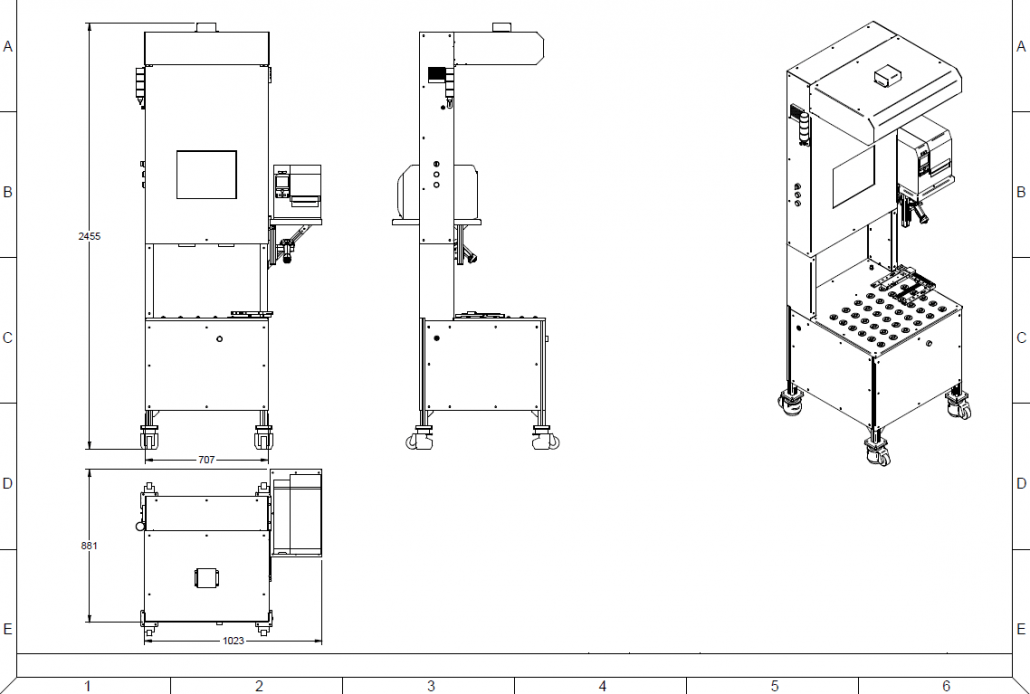

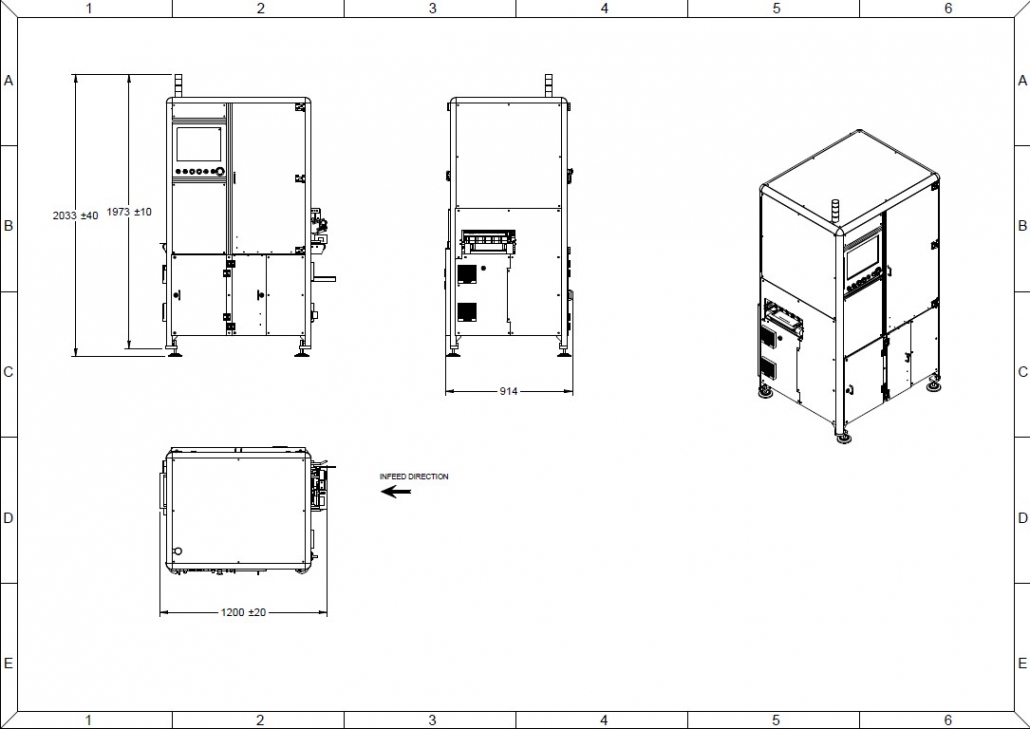

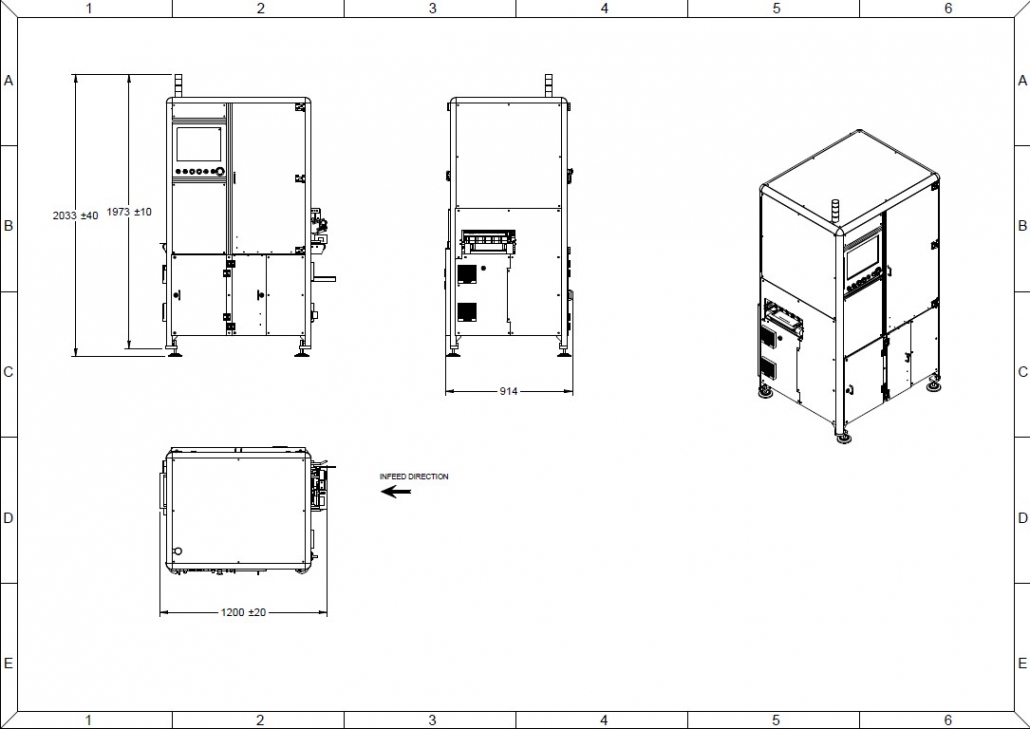

Automatic Scanning Machine

The Automatic Scanning Machine is specially designed for Online scanning of 1D/2D code present on the side of the box and in line with the Existing Conveyor System.

Designed to facilitate overall more productive operation with simple maintenance.

Features

- Plug & Play System

- User-friendly Operation Panel

- High-speed 1D/2D code Scanning Algorithm

- A vibration-free belt conveyor with a rejection bin. Polycarbonate enclosure.

- Traffic management maintains a gap between consecutive boxes, which reduces rejection and rework.

- Mirrorless multiple-resolution smart cameras with customized optics

- Robust 1D/2D code reading algorithm, which ensures minimum false rejection.

- State-of-the-art reflection-free illumination for more accurate shrink pack 1D/2D code decoding.

- Innovative design to accommodate the print and apply equipment within the machine.

- High-resolution camera to scan and verify the 2D Code on the box label.

- Integrated software can communicate with multiple cameras in the system.

- If the 1D/2D code is not scanned, the system does not apply the label on the Box. This avoids label wastage.

- Label roll changeover without stoppage of the production line.

- Various interlocks like rejection verification, rejection bin full, low air pressure, door open, etc.

| Parameter | description |

|---|---|

| Automatic Scanning Machine | • Camera - High resolution camera for box code scanning • Lens – Suitable high-resolution lens with minimum distortion is provided based on camera model. • Illumination - White LED, reflection free homogeneous illumination for reflective surface (inside plastic scanning) • Audible & Visual alarm • Sensors (as applicable) – Object, Target, Label detection, rejection verification sensor and rejection bin full sensor • Ejector -Pneumatic pusher with rejection bin • Conveyor with Traffic management to maintain gap and avoid jamming. • Print and apply labelling unit camera to inspect label 1D/2D /QR Code |

| PC | • Processor Group - Intel Chipset High speed controller, above 2.2 GHz • Operating System – Windows 10 Pro • Memory Capacity - 4 GB • Storage Capacity - 120 GB SSD • Display Size – 15” or 17” • Operator interface – LED/LCD and touch screen |

| Embedded I/O controller with embedded software | • I/O Controller – Processing & Controlling hardware signal and communicating with software, this controller integrates with sensor, electrical/electronic parts. • Camera communication • I/O Communication • Solid State Relay card • Required cables |

| Material of Construction | • Section frame, Structure, Plates – Aluminium • Covers – SS304 |

| External communications | • RS232, Ethernet, USB |

| Operating temperature | • 5°-40°C |

| Power supply | • 230 Volt AC, single phase with MCB for protection |

Products listed: Automatic Scanning Station 1 | Multi Scanning Station 2 | Manual Scanning Station 3 | Product Diverting Station | Control System