Coding and Marking on Building Material

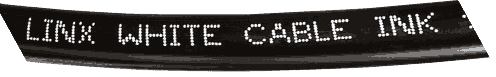

The construction industry relies on hard-core materials likewise cement, tiles, and wood for building projects. In the first place, these building materials used in challenging conditions need reliable coding and marking solutions. Our printer not only offers hassle-free printing but also provides an IP 65 rating for continuous production lines. Moreover, it can perform in dusty environments without the need for compressed air. Also, the Linx printer comes in a robust stainless steel body that can withstand various temperatures. Furthermore, Linx inks can work on rough construction materials like wood, PVC pipes, cables, bricks, blocks, stones, and synthetic papers. Let our coding and marking solution streamline your construction process coupled with removal of coding errors.

LOT and Batch Coding on Building Material Packaging

In general, Linx offers innovative inkjet coding and laser marking solutions for construction and building material packaging. Our sealed printheads and IP-rated enclosures ensure efficient coding with great accuracy to demonstrate. Moreover, it can easily print even on abrasive materials without contact. Linx coders allow for high contrast as well as nonerasable code on a wide range of substrates. Likewise, metal, timber, glass, and plastics make them ideal for harsh environments and difficult substrates. Trust Linx for easy-to-use, cost-efficient, and reliable coding and marking solutions that meet all your coding expectations.

Construction Industry | Coding and Marking Solutions

The construction industry prefers inkjet coding and laser marking to mark building materials like metal, glass, paper, and rubber. These printers can print expiry dates, QR codes, barcodes, and data matrix codes directly on the product. Other technologies like Continuous Inkjet Printers (CIJ), Laser Coders, and Thermal Transfer Over printers (TTO) are also available. As the Authorized Distributors for Linx Global, we provide sales and maintenance services to major industries. Guaranteed competitive prices and 24/7 emergency services to support the needs of the construction industry. Contact us today for the best coding and marking solutions for your building and construction material packaging.

Related Products

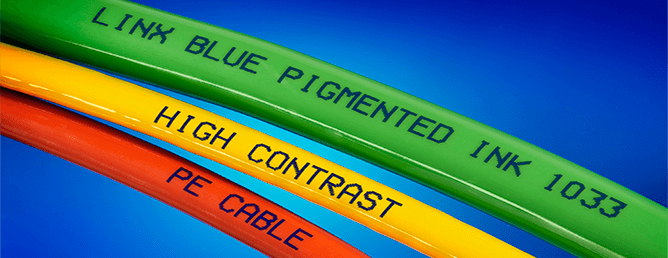

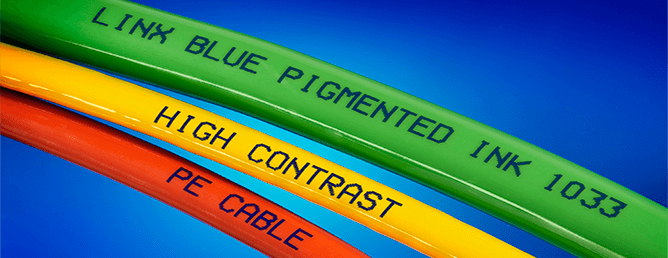

Linx inkjet coding and marking solutions explicitly cater to the extrusion industry for various applications. Moreover, these versatile printers allow easy mounting and mobility to accommodate different production line requirements. Indeed, making them ideal for marking a wide range of extruded products.

Some standard extruded products that can benefit from inkjet coding and marking solutions include:

- Cable and wire

- Tubes

- Guttering

- PVC pipes

- Panels

- Double-glazing window frames

- Molded parts

- Construction materials

- Industrial pipes and cables

- Connectors

- Aluminum profiles

- Metal elements

- Rubber

Linx Printing Technologies UK

Overall, Linx coders specialize in delivering high-quality prints at fast speeds, making them suitable for various coding requirements within the extrusion industry.

In addition to inkjet coding, laser coding options are also available, depending on the substrate material. Laser technology provides several benefits, including:

- Code longevity: Laser-marked codes do not degrade over time or during storage, ensuring long-lasting legibility.

- Variety of code sizes: Lasers can produce codes in various sizes to suit specific product and application requirements.

- No drying time: Since no involvement of ink, there is no need to wait for codes to dry, eliminating the risk of smudging.

Laser coding can be an excellent alternative option to print on specific substrates within the extrusion industry. When selecting a coding solution, consider factors such as substrate material, production speed, required print quality and durability, and the complexity of the design. Each method has advantages and limitations, so choose the one that best fits your needs and requirements.

Importance of Coding and Marking Printers in the Extrusion Industry

Coding and marking printers play a vital role in extruded materials’ identification, traceability, and compliance. Several types of printers are available for coding and marking extruded materials, each with unique advantages and limitations. When selecting a coding and marking printer for extruded materials, consider factors such as the type of material, production speed, required print quality and durability, and the complexity of the design. Each method has advantages and limitations, so choose the one that best fits your needs and requirements.

There are several methods for printing and marking on cables, each with its own advantages and limitations. Here is an overview of some standard marking on cable techniques:

- Inkjet Coding: Continuous Inkjet (CIJ) printers and Thermal Inkjet (TIJ) printers are popular choices for cable marking. These non-contact methods can print directly onto moving cables on a production line.

Continuous Inkjet Printer:

CIJ printers use a continuous stream of ink droplets that are deflected by an electric field to create the desired markings. They are suitable for high-speed production lines and offer excellent adhesion on various cable materials. - Thermal Inkjet Printer:

TIJ printers use heat to expel ink droplets from nozzles to mark on cable explicitly. They produce high-resolution prints and are ideal for applications requiring fine details or smaller text. - Laser Marking Machine:

Laser marking uses a focused laser beam to create precise, high-contrast marks on the cable surface. This non-contact method is suitable for various types of cables, including those made of plastic, rubber, or metal. Laser marking offers high precision, durability, and flexibility, making it ideal for marking logos, barcodes, and other intricate designs.

High-Speed Cable Marking Solutions

For high-speed production environments, choose a marking system specifically designed for fast production lines. These printers should be able to keep up with the speed of the production line while maintaining accurate and legible prints. Look for features like automatic printhead cleaning, low ink level alerts, and user-friendly software to ensure consistent print quality and minimize downtime.

When selecting a cable marking method, consider factors such as the cable material, production speed, required print quality and durability, and the complexity of the design. Each method has advantages and limitations, so choose the one that best fits your needs and requirements. Wire manufacturers prefer these fast inkjet coding and marking printers for mass production.

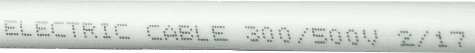

Inkjet coding printers are widely used for wire marking to print essential information directly onto products. The information published on cables and wires may include:

- Manufacturer’s name or logo:

This helps identify the brand and enhances brand visibility. - Product identification:

Marking model numbers, part numbers, or product codes help customers and installers quickly identify the specific type of cable or wire. - Technical specifications:

Wire gauge, conductor count, insulation type, voltage rating, and temperature rating are often printed on cables and wires. Also, ensures proper usage and compliance with safety regulations. - Industry standards and certifications:

Printing relevant industry standards (e.g., UL, CE, RoHS) and certifications to make the cable meet specific quality. - Sequential markings:

Identically these wire marking printers can print in meters or feet. Which helps users accurately measure and cut cables and wires during installation. - Batch or lot numbers:

These numbers help manufacturers trace products back to their production batch. Furthermore, it allows for quality control and tracking purposes. - Production date or expiry date:

The production date indicates when the cable or wire was manufactured. This information helps ensure proper stock rotation and adherence to warranty terms. Hence wire marking printers play a vital role in the cable industry. - Barcodes or QR codes:

These machine-readable codes can additional information about the cable or wire, such as its origin, production details, or technical specifications. Scanning the code can provide quick access to this information for inventory management, quality control, or installation purposes.

Inkjet Wire Marking Printers

Wire marking printers are an essential tool in the world of manufacturing and production. Inkjet Coders can easily do the marking on wire and cable for identification purposes. Whether you are working in the telecommunications industry or automotive industry, that requires precise labeling of lines. An inkjet wire marking printer can help streamline your operations and reduce errors. With the ability to print text, barcodes, and even logos, these printers suit your specific needs. So if you’re looking for a cost-effective and reliable way to improve your wire marking process. Contact us Today!

In general, the Linx inks can print with ease on flexible packaging with an inkjet coding machine. Variety of inks and fluids depending on the material and application requirements. Here are some popular ink types:

- Solvent-based Inks:

CIJ printers and some TIJ printers commonly use solvent-based inks. These inks contain pigments or dyes dissolved in a solvent that evaporates quickly. Indeed, leaving behind durable and high-quality inkjet printing on flexible packaging materials. Solvent-based inks offer good adhesion, quick drying times, and resistance to chemicals and abrasion. - Water-based Inks:

Water-based inks are suitable for use with some TIJ printers and flexographic printing systems. These inks contain pigments or dyes suspended in a water-based solution, making them more environmentally friendly than solvent-based inks. Water-based inks work well on porous substrates, such as paper and uncoated flexible inkjet packaging materials. But may not adhere well to non-porous materials without surface treatment. - UV-curable Inks:

UV-LED inkjet printers use UV-curable inks and offer excellent adhesion, durability, and resistance to chemicals and abrasion. These inks contain photoinitiators that cure instantly when exposed to UV light. Additionally, creating high-quality inkjet coding on various flexible packaging materials, including plastic films and laminates. - Hot-melt Inks:

Thermal transfer over printers (TTO) uses hot-melt inks, also known as solid inks. Also, some drop-on-demand (DOD) inkjet printers use hot melt inks. These inks come in solid form, and the print head melts the ink during the printing. As a result, transferring it from a ribbon onto the flexible packaging material. Hot-melt inks offer good adhesion and durability, making them suitable for printing on thin films and labels.

Buy the best inkjet coder for packaging.

When selecting the best ink for inkjet coder for printing flexible packaging printing, consider factors such as the printer type, packaging material, production speed, required print quality and durability, and environmental considerations. Each ink type has advantages and limitations, so choose the one that best fits your coding and marking requirements.