Linx date coders offer versatile date coding capabilities. Including pre-programmed formats, custom date time formats, Julian dates, and automated date-forward functions. Linx coders can effortlessly print best-before dates in the chosen format. Allowing industries to fulfill regulatory compliance and secure product traceability. In food and beverage industries, implementing date coder is mandatory to ensure consumer safety and comply with federal regulations.

Date Coder for Printing Directly onto Products

Date coders are indispensable components of production lines to imprint date codes on products and packaging with high precision. Typically, these machines are continuous inkjet printers, capable of applying fixed and variable data during un-interrupted production processes. Date coder printing whether affixed to products, packaging, or labels serves a critical function by informing end-users about product shelf life. Furthermore, the date coding of consumables such as food, beverages, pharmaceuticals, and medical products is strictly regulated by international laws to ensure consumer safety and compliance.

Primary date codes

Generated by date coders include:

- Best before date

- Expiry date/expiration date

- Use-by date

- Manufacturing date

The specific type of date code printed by a date coder is contingent on the nature of the product’s legal requirements. These date codes, batch, or lot numbers are frequently in-corporated to enhance product trace-ability and quality control.

When date codes are synchronized with batch numbers, they streamline internal tracking systems by encapsulating all pertinent production information. These codes can be meticulously printed on the primary packaging and the product itself, facilitating seamless integration into the supply chain.

Deploying date coders is not only pivotal for regulatory compliance but also for maintaining product integrity. The precision offered by these devices ensures that manufacturers can meet stringent quality standards while fostering consumer confidence through verifiable product freshness and safety.

Date Coding | Manufacturing date | Expiry date | Use by date | Best before date

As a professional in the industry, we understand the importance of accurate and clear expiration dates on your products. That’s why investing in a date-coder printer is essential for any manufacturing or packaging operation. With this technology, you can ensure that each product leaving your facility is labeled with an expiry date that is easy to read and meets regulatory requirements. In addition, These printers offer a range of features such as adjustable printing speed, high-resolution mark, and multi-line coding, making it easier to customize the printing process to match your specific needs. Likewise, investing in a date coder printer ensures your products have accurate labeling for successful distribution.

Applications of Time & Date Coding

Date coding is a crucial process utilized across multiple industries, including pharmaceuticals, automotive, electronics, cabling, and cosmetics. To meet the diverse needs of these sectors, date coder systems must be versatile, efficiently handling various products and packaging materials. The food and beverage industries are the most prominent users of date coding technology.

Expiration Date Printing in the Food Industry

Expiration Date Printing in the Food Industry

In the food sector, date coders are positioned on production lines to mark each batch with essential information such as the best-before date, lot number, and production date. Whether dealing with ready-made meals, cookie boxes, or glass jars, accurate coding is mandatory. Legal requirements aside, these codes assure customers of the product’s freshness and quality.

Date coders in the food industry must offer ink that is both legible and highly adhesive. Moreover, they must keep pace with the high speeds of modern production lines to ensure efficiency and reliability.

Date Coding in the Beverage Industry

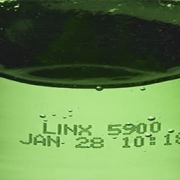

Speed is equally critical in the beverage industry. High-speed Continuous Inkjet (CIJ) printers are employed to mark expiration dates on glass bottles, PET bottles, and metal cans.

Date Coding in the Beverage Industry

Beverage bottling lines often face the challenge of condensation, especially at low temperatures. Our printers address this issue by using high-adhesion inks that ensure codes remain intact despite moisture. Additionally, small-character CIJ machines are ideal for marking compact areas such as bottle caps. For surfaces like dark glass bottles, pigmented inks provide excellent contrast, ensuring clear and readable codes.

By leveraging advanced date coding technology, businesses across various industries can enhance product traceability, comply with regulations, and build consumer trust through guaranteed freshness and quality.