Date Coding

Date coding printers for printing manufacturing and expiry date onto the product in detail. Offering a comprehensive range of date coders, including Inkjet Coding, Thermal Transfer, and Laser Marking Machines. …More Info

Case Coding

Case coding solution for printing variable text, barcodes, and logos directly onto porous and non-porous substrates. Moreover, These case coders can easily print on corrugated shipping containers, cardboard boxes, cartons, and cases at the time of product packaging. …More Info

2D Coding

2D coding solution for explicitly marking QR, Dot, and Data matrix codes. In short, the difference between linear and 2D barcodes is the type and amount of data they can hold. 2D codes are significantly more traceable than barcodes as they can hold more data. …More Info

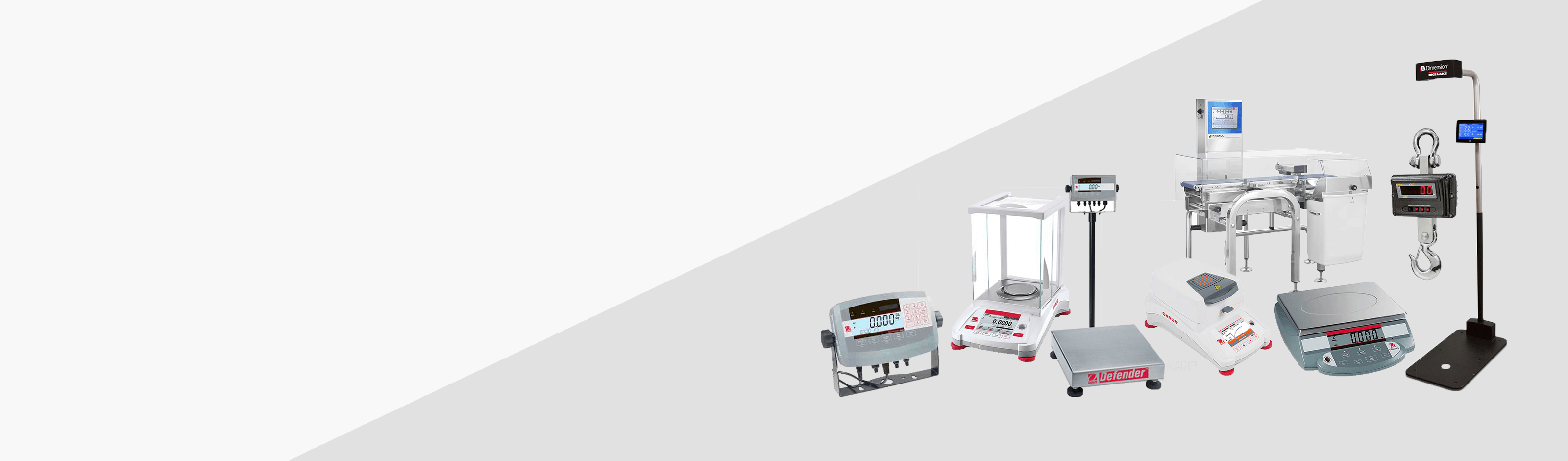

Industrial and Retail Weighing Scales

Our product line comprises various weighing scales for dynamic and static applications. We have everything from the Industrial sector to retail and supermarket scales. Moreover, we provide control weighing solutions as per customers’ requirements. …More Info

Truck Weighing Scales

Truck Weighing Scales Manufacturer and Suppliers in UAE and overall Middle East. Especially providing factory-manufactured and customized-size weighbridges integrated with electronic equipment for weighing heavy-duty trucks and trailers. …More Info

Services

Reliable Scales & Equipment Services is authorized by (ESMA) Emirates Authority For Standardization and Metrology to provide weighing scale repair and maintenance services. …More Info

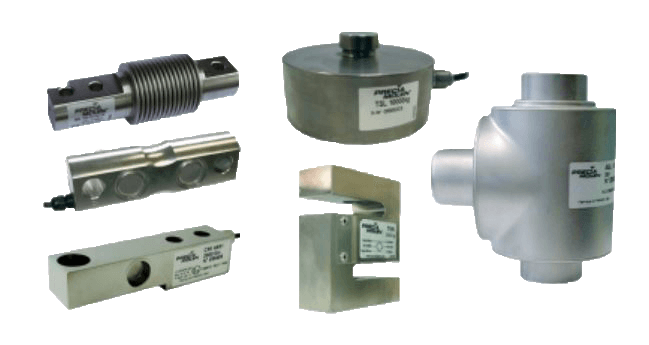

Weighing Spares

Reliable offers a range of spares and accessories, mainly for weighing equipment. Also, it specializes in supplying and installing different types of load cells for various applications. …More Info

Calibration

Reliable Calibration & Measurement Laboratory – ISO 17025:2017 accredited by Emirates International Accreditation Centre (EIAC). …More Info

Complete Industrial Automation Solutions

In the first place, we provide inkjet coders and laser marking printers for primary date printing. The inkjet coder can not only code expiry and best-before dates but also prints LOT and batch codes. As a matter of fact, these printers are the basic requirement of every manufacturer. In like manner, the case coding printer integrates at the secondary packaging stage. Here, the end user needs to code and mark on the carton, boxes, and cases. In addition, our laser marking printer provides 2D coding and Datamatrix solution for fast-moving consumer goods. When the above coding solution gets coupled with our static and dynamic weighing scales. Reliable Industrial Automation becomes the complete production line solution provider all under one roof in the same way.

Moreover, end users must mostly print high-resolution large characters on pallets and shipping containers at the secondary packaging stage. This is where our DOD (Drop on Demand Printers) and LCM (Large Character Marking Printers) becomes equally important. Also, we provide handheld printers where the production is not high and manual printing is acceptable. Finally, we come to the implementation of truck weighing scales which delivers precision and accuracy of the finished goods to the manufacturer.

Continuous Ink Jet Printer

CIJ is an acronym for continuous inkjet in detail. In CIJ printers, ink is pumped from a reservoir and ejected through the nozzle with up to 120,000 electrically charged droplets to form characters and text. …More Info

Laser Marking Machine

Looking for a printer to do marking and etching on your products or materials explicitly? Try the Linx laser marking machine. It is designed explicitly for detailed markings and centrally controls the printer with easy-to-use software. …More Info

Thermal Transfer Over Printer

Thermal Transfer Over printer is a cutting-edge printing device in detail. In addition, it offers high-resolution printing capabilities for various flexible packaging materials. A thermal printhead alongside a thermal transfer ribbon to imprint wax and resin-based ink onto the substrate. …More Info

Date Coding & Marking Printers | Weighing Scales & Truck Scales

Inkjet Date Coding Printers | Laser Marking Machines | Thermal Transfer Printer | Case Coding Printers | Weighing Scales | Truck Weighing Scales or Weighbridge