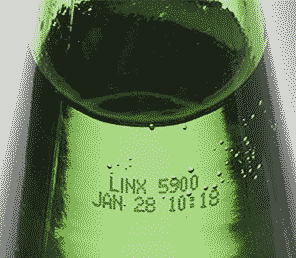

Date Coding on beverage bottles and cans

Inkjet coder for the beverage industry identically ensures product safety; authenticity is critical to manufacturers. To achieve this goal, businesses need reliable date and batch coding solutions to trace their products quickly wherever they may be in the world during a recall. One effective solution is using industrial coding and marking printers especially designed for the beverage industry. These printers can accurately print date and lot codes on bottles, cans, as well as on other packaging. Also, providing the necessary traceability through linear or Datamatrix barcodes, batch numbers, and manufacturing date information. In the beverage industry, selecting the correct type of date-coding printer for your specific production line is equally important.

Inkjet coder for the beverage Industry

Indeed for beverage production companies, date coding on beverage bottles and cans remains crucial for the traceability of the product. Our range of inkjet printers and laser coders can print at high speeds despite various substrates. These substrates chiefly include bottles, cans, caps, and other plastic items. These machines can produce clear and accurate manufacturing dates, batch codes, and additional critical information. Whether your production line runs continuously or intermittently, our coding solutions are compatible with all processes. Linx date coding solutions ensure that your beverage products are within the regulations.

Find a suitable option for your printing needs

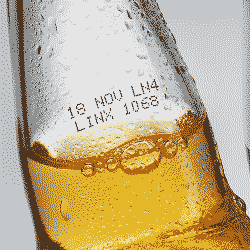

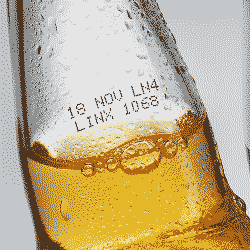

Industrial date coding on beverage bottles and cans is made easy with the use of continuous inkjet printers and laser coders. With special adherence inks, printing on cold fill applications is possible, and even condensation won’t interfere with the quality of the print. Fast-drying inks and yellow and white ink options allow for contrast on dark materials, including clear glass bottles. These printers also boast a quick and clean start every time, even after shutdown, and long printhead cleaning intervals of up to three months to avoid excessive maintenance requirements. Customizable interfaces make it easy to use functions that you regularly need. Laser coders do not require expensive factory air for cooling, and they are IP65-rated, enabling easy cleaning in washdown environments. With no consumables, the total cost of ownership is kept down, which is excellent for the environment and for your cash flow.

Easily print Date and Batch Codes on Glass Bottles

If you’re wondering how to print an expiry date on glass bottles, a few options are available. Date coding on beverage glasses can be done using two types of printing technologies: continuous inkjet printers and laser coders. Choosing the right product technology depends on factors such as the color of the substrate, production environment, and line speed. For example, if you need to print on clear glass bottles, laser coding may be a better option as it provides high-contrast printing that stands out. On the other hand, if your production speed is higher and you’re printing on darker glass bottles, continuous inkjet printers may be a better choice, as they can handle faster line speeds and provide legible codes. Ultimately, understanding your specific needs will help you make the right choice regarding bottle coding on glass.

Enhance the visibility of your product information

As a manufacturer or distributor of beverages, ensuring product safety and quality is the top priority. One way to achieve this is by imprinting best-before dates or batch codes on the bottles or cans. Where to print these codes, however, can be a concern. That’s where our coders come in, offering complete flexibility in printing options. From the curved surface of the bottle to the bottom and even the cap, our inkjet coder for the beverage can print the required information per your specific needs. With our state-of-the-art technology, you can rest assured that your products are correctly labeled and ready to go to market.

Special Adherence Ink

Printing Date and LOT Codes on Beverage Products

Regarding beverage production, ensure the correct coding of your products to keep your show running smoothly. Our solutions offer flexibility with options for time-delayed coding, encoder speed-based coding, and product detection using sensors. But what really sets us apart is the durability of our products. With an IP rating of IP55 / IP65, our coding solutions can withstand even the harshest production environments.

And with precision manufacturing, you can trust that our robust units will keep your production running without interruption. In fact, our inkjet coder for the beverage industry allows you to mark directly onto your bottle or can. This process eliminates the need for a paper label which makes the process more efficient than ever. Contact us to see how our user-friendly and easy-to-install solutions can increase your production output. Moreover, it helps reduce the risk of errors and rework.

Different Types of Printers for a Variety of Applications

The beverage industry is always looking for ways to improve its product offering. And a vital aspect of this is the ability to code and mark bottles with important information. This is where an inkjet coder for the beverage industry comes in as an essential piece of printing equipment. Moreover, it allows for continuous inkjet printing, laser marking, and other coding forms. These types of printers can print batch codes, date codes, expiry dates, and manufacture dates with high accuracy and speed. Linx printers can print QR codes and barcodes for easy tracking and inventory management.

As a Linx authorized distributor in UAE, we offer high-quality inkjet coders at competitive prices for our customers’ needs. We also provide maintenance contracts, free delivery, and 24/7 emergency service to ensure your production line never stops running.

Related Products

Inkjet Coding and Marking Solutions

A continuous inkjet (CIJ) coding printer (non-contact printing technology) can quickly print high-quality codes, text, and graphics on various substrates. Food, beverage, pharmaceuticals, and packaging industries mostly use CIJ for marking batch numbers, expiry dates, and barcodes. Here’s an overview of how a CIJ coder works:

Continuous Inkjet Printer Workings

- Ink System:

The Continuous Inkjet printer has an ink system so that it can reserve ink. The ink, which typically contains solvents, dyes, or pigments, circulates continuously through the system. - Ink Pressure and Circulation:

CIJ pressurizes the ink and pumps it from the reservoir to the printhead. After passing through the printhead, CIJ collects the unused ink and returns it to the reservoir for recirculation. - Printhead and Nozzle:

The printhead contains a nozzle with a small opening, usually ranging from 40 to 70 microns in diameter. A piezoelectric crystal inside the nozzle vibrates at a specific frequency, typically between 60,000 and 120,000 times per second. - Droplet Formation:

As the pressurized ink enters the vibrating nozzle, it breaks into individual droplets due to the vibration effect. These CIJ droplets release in a continuous stream from the nozzle. - Charge Electrode:

Immediately after the droplets exit the nozzle, they pass through a charged electrode. The electrode imparts an electrostatic charge to each droplet, depending on the intended position of the printable character. - Deflection Plates:

The charged ink droplets travel through a pair of deflection plates, which create an electric field. Depending on the droplet charge with a more or less electric field, determining their position on the substrate. - Printing on the Substrate:

The accurately deflected CIJ droplets reach the substrate, creating the desired characters or graphics. Meanwhile, the non-deflected droplets fall into a gutter and return to the ink reservoir for recirculation. - Drying and Curing:

As the ink droplets land on the substrate, the solvents evaporate quickly, leaving behind the ink on the surface. This process results in a high-quality, permanent print that is resistant to smudging and fading.

Print with Food Grade Inks

The Continuous inkjet coder’s ability to print directly on moving products makes it an ideal choice for many industrial coding applications. Additionally, the technology offers high-speed printing, low maintenance requirements, and the capability to produce high-resolution prints with minimal downtime.

Expiry Date Printer

Continuous Inkjet Printers are popular for printing variable information, such as dates or batch codes during production. These printers explicitly handle products of different sizes, shapes, or textures, making them prime for many industries. Furthermore, Linx Printing Technologies offer a range of continuous inkjet printers that are cost-effective and efficient. Some features include remote printer monitoring and customer support, concealed and easy-to-clean printheads, error-free touch-screen control, and simple self-service capability. Compared to other industrial inkjet coders, Linx’s printers provide a reliable and quality solution to meet your needs.

Linx 8900 Continuous Inkjet Printer (CIJ)

This printer delivers efficient output with the help of a remote application to keep you in control anytime and anywhere. Moreover, Linx CIJ allows you to print up to six lines, including barcodes, batch coding, and QR codes. Therefore it’s perfect for high-speed production, retail packaging, and 24/7 operations.

Linx 8900 inkjet coder has popularity because of its remote access, control, and support through the Linx PrinterNet. This allows for error-free coding by enhancing your monitoring and control capabilities. Additionally, it features a quick operation with a touchscreen interface, self-service, and minimal intervention to maximize production uptime. The Linx 8900 CIJ Printer allows you to print onto both primary and secondary packaging. Hence, one printer further makes your printing process easy.

Take your production to the next level with the Linx 8900 Continuous Inkjet Printer.

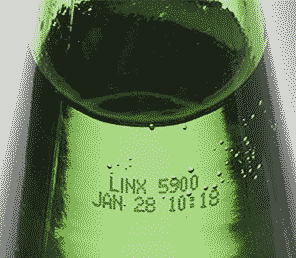

In the fast-paced beverage manufacturing industry, it’s imperative to have reliable and efficient printing solutions. That’s where Linx continuous inkjet printers and laser marking machines come in. With the ability to print on plastic and glass bottle caps, manufacturers opt for these printers gradually. Indeed, Linx printers offer an ideal solution for expiration dates and LOT codes. And with continuous printing capabilities from the top of the production line, there’s no need to slow down the process. So, whether you want to print expiry dates or etch intricate designs onto bottle caps, Linx has you covered.

In various industries, date/time and batch or lot numbers needs printing onto bottle caps instead of bottles or labels. But, as bottle caps present a challenge of small circumference and hard-to-code materials, finding an efficient solution can be difficult. Thankfully, with the right bottle coders, printing onto metal or plastic caps is possible and a breeze. Our bottle printing technology enables small character printing that is legible and readable throughout the product’s shelf life.

Inkjet Coder to Print on Bottle Cap

Inkjet coding is an efficient and precise way of printing information onto bottle caps. Whether it be expiry date, batch number, or QR codes. With the ability to continuous printing on fast-moving production lines, inkjet coders became crucial. Opting for solvent- or water-based inks depends entirely on the material and the desired print quality. The use of inkjet coders guarantees reliable and high-speed printing, ensuring that the production process runs smoothly and efficiently. As such, inkjet coding has become essential in the packaging industry.

Laser Marking Machine for Etching

Laser etching on bottle caps plays a vital role in the world of product labeling. The application of this technology makes it possible to accurately print or engrave expiry dates or LOT codes right onto the bottle cap itself. Unlike traditional printing methods, the laser etching process is non-contact and does not involve any ink. Indeed, the caps can last well beyond the life of the product. Bottle cap printing or etching is a reliable and cost-effective solution, especially for industries requiring strict adherence to regulatory guidelines. It ensures the protection of consumers by allowing manufacturers to keep track of their products lifespans and avoid potential hazards. Laser etching on bottle caps is an innovative and practical way to keep products safe, and consumers informed.

Print expiry date on glass bottles using various methods, each with its advantages and limitations. Here are some popular options for printing expiration dates on glass bottles:

- Continuous Inkjet (CIJ) Printers:

Linx CIJ printers are widely used to print expiry date on glass bottles because they can print directly on moving products on a production line. Moreover, They offer high-quality, durable prints and can handle the curved surfaces of glass bottles. Choose an ink specifically designed for glass surfaces to ensure proper adhesion and durability. - Thermal Inkjet (TIJ) Printers:

TIJ printers identically use heat to eject ink droplets from nozzles onto the glass surface. They produce high-resolution prints and are suitable for applications requiring details or text explicitly. As with bottle expiry date printer, select an ink that is compatible with glass surfaces for optimal results. - Laser Marking Machines:

Laser marking is a non-contact method that uses a focused laser beam to create precise, high-contrast marks on the surface of glass bottles. This method provides high precision and durability, making it ideal for marking expiration dates. CO2 lasers or UV lasers are typically used for marking on glass surfaces, as they offer excellent contrast and minimal damage to the substrate.

When selecting a method for printing expiration dates on glass bottles, consider factors such as the production speed, required print quality and durability, and the complexity of the design. Each method has advantages and limitations, so choose the one that best fits your needs and requirements.

High-precision bottle expiry date printer

Get accurate and reliable glass bottle markings with our inkjet coding and laser marking printers.

Fast coding for bottling lines

Improve your beverage production with our high-speed inkjet and laser printers for expiry dates and batch codes.

Boost labeling efficiency

Maximize productivity with our cutting-edge inkjet coding and laser marking printers for glass bottle expiry date printing.

Continuous Ink Jet Printer

Continuous Ink Jet Printer (CIJ) – High-speed, non-contact printing technology in time. Industries prefer these printers for coding and marking product and packaging information. It prints product data likewise, batch numbers, expiry dates, barcodes, QR codes, and logos on a wide range of materials.

Linx Global is a leading manufacturer of inkjet coding solutions and ink-jet printers. These printers are known for their ease of use and their need for very low maintenance. Linx CIJ best fits businesses looking to improve their coding and marking quality.

Benefits of Linx Global CIJ Printers in detail:

InkJet Coder for Printing Expiry Dates

- High-speed printing:

Linx continuous ink-jet printers can print easily despite fast-moving production lines and ensure minimal downtime. - Non-contact printing:

The CIJ technology allows non-contact printing with the substrate in detail. Indeed it enables coding on uneven surfaces and reduces the risk of damage. - Wide range of inks:

Linx offers a variety of ink types, such as food grade, pigmented, and special inks. - Easy setup and operation:

Continuous ink-jet printers feature provides not only user friendly access but also a quick change of ink systems. As a result, this makes them easy to set up, operate, and maintain. - Robust design:

Linx continuous inkjet printers can print in harsh environments coupled with sealed print heads to protect against dust and moisture. - Low maintenance:

CIJ printers require minimal maintenance with self cleaning print heads in effect. Also, it provides automatic diagnostics, ensuring optimum performance and reduced downtime. - Connectivity and integration:

Above all, These printers offer various connectivity options and can be easily integrated with existing production lines.

Overall, Investing in a Linx Global Continuous Ink-jet Printer can achieve clear coding and marking directly on your product.

The best printer for coding and marking on bottles depends on various factors. Such as the bottle material, production speed, required print quality, and durability. Here are some popular options for coding and marking on bottles:

- Continuous Inkjet (CIJ) Printers:

CIJ printers became popular for coding on bottles because they can print directly on moving products on a production line. They offer high-quality, durable prints and can handle curved surfaces of various bottle materials, including glass, plastic, and metal. CIJ printers are suitable for high-speed production lines. - Thermal Inkjet (TIJ) Printers:

TIJ printers use heat to eject ink droplets from nozzles onto the bottle surface. Moreover, They produce high-resolution prints and are suitable for applications requiring fine details or smaller text. TIJ printers work well on various bottle materials and can provide high-quality codes even at lower production speeds. - Laser Marking Machines:

Laser marking is a non-contact method that uses a focused laser beam to create marks on the surface of bottles. This method offers high precision, durability, and flexibility, making it ideal for marking logos, barcodes, and other intricate designs. Laser marking machines work well on both glass and plastic bottles.

Each method has advantages and limitations, so choose the one that best fits your needs and requirements.

Bottle Coding | Plastic & Glass Bottle Printing

Linx provides reliable and consistent bottle coding and marking solutions to minimize rework. Our printers and coders can easily integrate into production line systems, accommodating various line speeds. Automated date, time, code, and number series functions reduce manual interventions and avoid line downtime. We offer specialized coding solutions, such as UV visible inks and permanent laser marking, suitable for both luxury brands and anti-counterfeit product identification.

Our bottle coding printers are perfect for high volume expiration date coding or batch identification, as they can print directly onto plastic or glass bottles in almost any orientation and mark variable information, including barcodes and data matrix, and QR codes, and decrease waste and environmental impact. With profound experience in creating coding and marking equipment, we understand the unique challenges presented by printing on bottles, and our coding technologies have been specifically designed to meet them. Linx bottle coders are used across various industries, such as food, beverage, cosmetics, FMCG household products, pharmaceutical, and chemical bottling, and can help minimize production costs and improve rates.

Efficiency is essential when it comes to bulk coding on glass bottles. This is where inkjet coding and laser marking come in. With the use of continuous inkjet technology, printing onto glass bottles can be done at lightning speed without sacrificing precision. On the other hand, inkless laser coding uses etching and engraving technology to create characters on the surface of the glass. Both methods are perfect for glass bottle coding. Moreover, it can print important information like expiry dates and batch codes, making it easy to keep up with production demands. When it comes to high-speed production lines, Linx printers are the perfect choice for accurate and efficient printing on glass bottles.

Continuous Inkjet (CIJ) Printers for Glass bottle coding

CIJ printers specialize in coding on glass bottles because they can print directly on moving products on a production line. They offer high-quality, durable prints and can handle the curved surfaces of glass bottles. Choose an ink specifically designed for glass surfaces to ensure proper adhesion and durability.

Thermal Inkjet (TIJ) Printers

TIJ coding printers use heat to eject ink droplets from nozzles onto the glass bottle surface. They produce high-resolution prints and are suitable for applications requiring fine details or smaller text. As with CIJ printers, select an ink that is compatible with glass surfaces for optimal results.

Laser Marking Machines

Laser marking is a non-contact method that uses a focused laser beam for coding on the surface of glass bottles. This method provides high precision and durability, making it ideal for marking expiration dates. CO2 or UV lasers specialize in marking on glass bottle surfaces. Indeed, they offer excellent contrast and minimal damage to the substrate. Linx fiber laser can quickly provide etching and engraving of character on glass bottles. Moreover, these printers specialize in coding at high-speed production lines.

Linx-pigmented inks offer a durable option for coding on plastic bottle. Moreover, these printers can print batch numbers and expiry dates on various colored plastics. Indeed specializes in polyethylene (PE or PET), polypropylene (PP or OPP), PVC, and Nylon. These inks maintain clarity for years, even when exposed to daylight.

Continuous Inkjet (CIJ) Printers for Coding on Plastic Bottles

CIJ printers became popular for coding on plastic bottles because they can print directly on moving products on a production line. They offer high-quality, durable prints and can handle curved surfaces of various bottle materials, including glass, plastic, and metal. CIJ printers are suitable for high-speed production lines.

Thermal Inkjet (TIJ) Printers

TIJ coding printers use heat to eject ink droplets from nozzles onto the plastic bottle surface. They produce high-resolution prints and are suitable for applications requiring fine details or smaller text. TIJ bottle coding printers work well on various materials and can provide high-quality codes even at lower production speeds.

Laser Marking Machines

Laser marking is a non-contact method that uses a focused laser beam for coding on plastic bottle. This method offers high precision, durability, and flexibility, making it ideal for marking logos, barcodes, and other intricate designs. Laser marking machines work well on both glass and plastic bottles.

Linx Inkjet coding solutions allow manufacturers to print on plastic bottles easily. Moreover, Linx CIJ is capable of printing multiple line characters at a high-speed production line. Inkjet printers have more preference over laser marking machines in the plastic bottle industry. Considering the aspect of plastic getting damaged over high-intensity of heating through laser. Most of industries prefer black ink coding on bottles as the standard color. But at Linx, we have a variety of ink and fluids for catering to all the needs of the industrial market.