What factors do you need to consider while buying a laser marking machine?

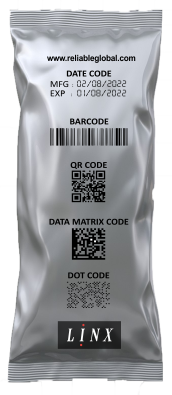

Laser marking printers for marking text or QR codes on tobacco and cigarette boxes have become the typical choice. While investing in a laser marking machine, it is important to consider factors such as optics and power requirements. The usage of lasers like CO2 lasers and Fiber lasers depends on the application or desired results. Some machines may also integrate vision components that detect irregularities in products before they are processed to ensure accuracy.