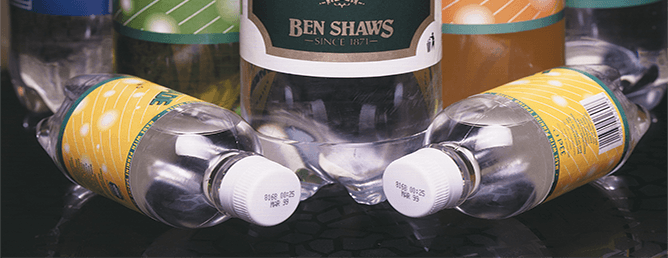

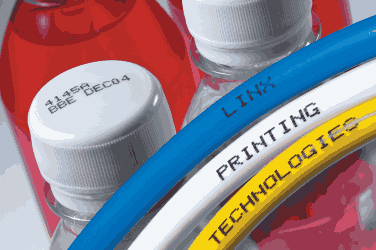

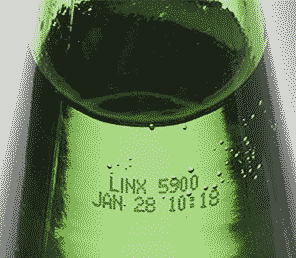

Bottle Coding Printers for the Beverage and Dairy Industry

In the evolving beverage and dairy industry, coding and labeling have become a need. As people become more health conscious and demand transparency in the products they buy. Manufacturers must ensure their products have clear batch codes and expiry dates printed. Investing in a bottle coding printer can smooth the process of labeling and coding bottles. Also, saves time and reduces the risk of human error. In addition, provides the ability to print quality codes and labels onto various surfaces. A bottle coding printer is essential for any beverage or dairy producer looking to stay in the market.

Avoid add-on costs due to rework with our coding solutions. Our solutions enable high speed and volume line bottle production with an error free code. Enables printing of the best-before date, lot codes, batch codes, logos, and other details to avoid down time. We offer inkjet, laser coding, and marking solutions for plastic and glass bottles and bottle caps.

Benefits of Beverage Coding Printer

Bottle coder printers offer several advantages to producers in a variety of industries. One of the key benefits of these printers is their high speed and accuracy. Which makes them ideal for printing batch numbers, expiry dates, and other important information on various packaging materials. In addition, bottle coder printers are easy to set up and maintain. Which helps to reduce production downtime and increase efficiency. They are also highly adaptable, able to print custom designs and logos. Overall, the advantages of bottle coder printers make them an essential tool for any business. Whether you want to streamline your operations or improve its product labeling and identification processes.

Bottle Coder: Continuous Ink Jet & Laser Marking System

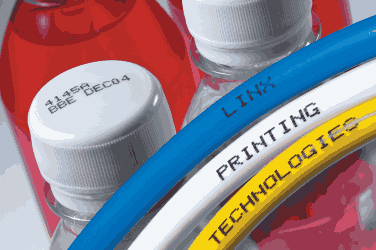

In the world of product packaging and labeling, precision and efficiency are key. At Linx Global, they understand the importance of accuracy and speed when it comes to coding and marking bottles. That’s why we offer a range of advanced bottle coders to cater to all kinds of coding needs. Covers complete printing solution with continuous inkjet, laser marking, and thermal transfer printers. As experts in the field, we provide the best solution to meet the demands of the packaging industry. When it comes to quality, Linx Global sets the standard for bottle coding printers.

Related Products

FREQUENTLY ASKED QUESTIONS

To ensure clear and easy-to-read expiry dates, the printing should be legible and placed prominently on the packaging, such as the front or back label. It is also essential to use food-grade ink when printing expiry dates on baked goods. These inks are safe for consumption, compliant with regulatory requirements, and designed to withstand baking while keeping the printed information legible and accurate.

Using food-grade ink that is safe for consumption and compliant with regulatory requirements is essential when printing expiry dates on baked goods. Regulatory authorities require food manufacturers to include expiry dates as part of food safety regulations, so compliance with these regulations is necessary to avoid fines or penalties and to ensure that products are safe for consumption. Therefore, it is important to ensure that the date coder being used meets all relevant regulatory requirements.

A continuous inkjet (CIJ) coding printer (non-contact printing technology) can quickly print high-quality codes, text, and graphics on various substrates. Food, beverage, pharmaceuticals, and packaging industries mostly use CIJ for marking batch numbers, expiry dates, and barcodes. Here’s an overview of how a CIJ coder works:

Components of a Continuous Inkjet Printer

- Ink System:

The Continuous Inkjet printer has an ink system so that it can reserve ink. The ink, which typically contains solvents, dyes, or pigments, circulates continuously through the system. - Ink Pressure and Circulation:

CIJ pressurizes the ink and pumps it from the reservoir to the printhead. After passing through the printhead, CIJ collects the unused ink and returns it to the reservoir for recirculation. - Printhead and Nozzle:

The printhead contains a nozzle with a small opening, usually ranging from 40 to 70 microns in diameter. A piezoelectric crystal inside the nozzle vibrates at a specific frequency, typically between 60,000 and 120,000 times per second. - Droplet Formation:

As the pressurized ink enters the vibrating nozzle, it breaks into individual droplets due to the vibration effect. These CIJ droplets release in a continuous stream from the nozzle. - Charge Electrode:

Immediately after the droplets exit the nozzle, they pass through a charged electrode. The electrode imparts an electrostatic charge to each droplet, depending on the intended position of the printable character. - Deflection Plates:

The charged ink droplets travel through a pair of deflection plates, which create an electric field. Depending on the droplet charge with a more or less electric field, determining their position on the substrate. - Printing on the Substrate:

The accurately deflected CIJ droplets reach the substrate, creating the desired characters or graphics. Meanwhile, the non-deflected droplets fall into a gutter and return to the ink reservoir for recirculation. - Drying and Curing:

As the ink droplets land on the substrate, the solvents evaporate quickly, leaving behind the ink on the surface. This process results in a high-quality, permanent print that is resistant to smudging and fading.

Expiry Date Printer

Continuous Inkjet Printers are popular for printing variable information, such as dates, batch codes, or expiry dates during production. These printers explicitly handle products of different sizes, shapes, or textures, making them prime for many industries. As a reliable expiry date printer, they are especially suited for sectors like food and beverage, where food grade inks are essential. Furthermore, Linx Printing Technologies offer a range of continuous inkjet printers that are cost-effective and efficient. Some features include remote printer monitoring and customer support, concealed and easy-to-clean printheads, error-free touch-screen control, and simple self-service capability. Compared to other industrial inkjet coders, Linx’s printers provide a reliable and quality solution to meet your needs.

Know More About Our Bestselling Continuous Inkjet Printer (CIJ) – Linx 8900

This printer delivers efficient output with the help of a remote application to keep you in control anytime and anywhere. Moreover, Linx CIJ allows you to print up to six lines, including barcodes, batch coding, and QR codes. Therefore it’s perfect for high-speed production, retail packaging, and 24/7 operations.

Linx 8900 inkjet coder has popularity because of its remote access, control, and support through the Linx PrinterNet. This allows for error-free coding by enhancing your monitoring and control capabilities. Additionally, it features a quick operation with a touchscreen interface, self-service, and minimal intervention to maximize production uptime. The Linx 8900 CIJ Printer allows you to print onto both primary and secondary packaging. Hence, one printer further makes your printing process easy.

Take your production to the next level with the Linx 8900 Continuous Inkjet Printer.

Industrial laser etching on cardboard is a non-contact, efficient, and eco-friendly method. Furthermore, it can print expiry dates, QR codes, lot codes, and more directly on the product surface. It works by using a focused laser beam to create precise, high-contrast marks on the cardboard. Despite of highly intense laser beam, it does not cause damage or deformation to the cardboard.

Industrial laser marking on cardboard

- Choosing the appropriate laser:

CO2 laser for etching on paper and cardboard materials due to their ability to produce high-quality marks with minimal damage to the substrate. The wavelength of CO2 lasers suits well for absorbing energy from organic materials like cardboard, which results in efficient and clean marking. - Generating the design:

Specialized software to create design, text, or code (such as an expiry date, QR code, or lot code). The software thereafter forwards the digital design to the laser system controller. - Focusing the laser beam:

The laser system particularly focuses the beam onto the cardboard surface for etching. This usually happens through a series of lenses or mirrors. The focused laser beam has a very high energy density, which enables it to selectively remove or alter the top layer of the cardboard material. - Etching the cardboard:

As the laser beam moves across the cardboard surface, it vaporizes or ablates the top layer of the material, creating precise and high-contrast markings. The process does not involve any ink or chemicals, making it an environmentally friendly option.

Advantages of using laser etching on cardboard

Laser etching is suitable for various applications, including marking on boxes of tobacco, perfumes, cereals, and many other products.

- High precision and quality: Creates accurate, legible, and durable markings, even on small or intricate designs.

- Fast processing speeds: Suitable for high-speed production lines, ensuring efficient operations.

- Non-contact method: Laser etching printers do not physically touch the cardboard surface. Overall, it reduces the risk of damage or deformation to the packaging.

- Eco-friendly: Eliminates the need for inks, solvents, and other consumables, reducing waste and environmental impact.

In general, laser etching is an effective marking technique for manufacturers looking to code on nonporous products.

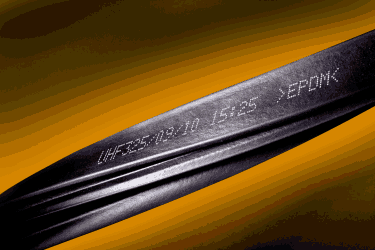

Laser marking suits the rubber industry, allowing direct etching and engraving messages on the product. The laser utilizes a focused beam of light to create high-contrast, precise, on the rubber surface. This process works well with various types of rubber, including natural rubber, synthetic rubber, and silicone.

Laser marking offers several advantages:

- High precision:

Fiber Laser provides highly detailed and accurate information, allowing for intricate designs, logos, barcodes, and text on rubber surfaces. - No contact:

Since laser marking results in a non-contact process, the rubber material has no physical wear. Also, it eliminates the need for consumables like ink and solvent. - Durability:

Laser marking rubber is resistant to abrasion, heat, chemicals, and UV exposure. Additionally, ensuring that the marks remain legible and intact throughout the product’s life. - Flexibility:

Fiber or CO2 Laser systems also have software programs to set different messages at variable speeds to print on rubber. - Speed and efficiency:

Laser rubber marking is fast, making it suitable for high-volume production environments.

Select the suitable laser type for laser marking on rubber, such as a CO2 or fiber laser. And adjust the parameters like power, speed, and frequency to achieve the desired result without damaging the printable material.

In conclusion, the laser is an effective and versatile method for the rubber industry. Manufacturers can achieve high-quality, durable, and precise printing of rubber products by selecting the right equipment.

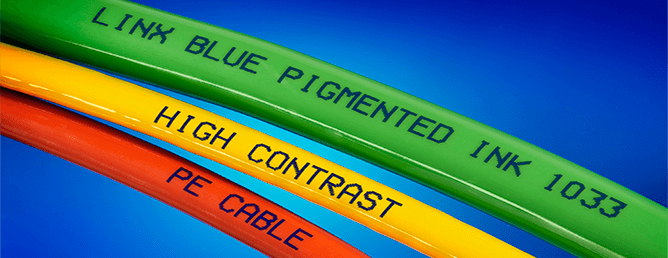

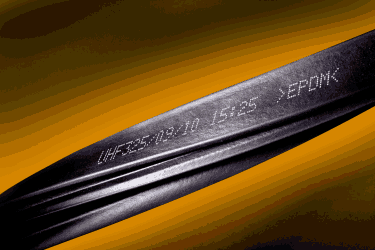

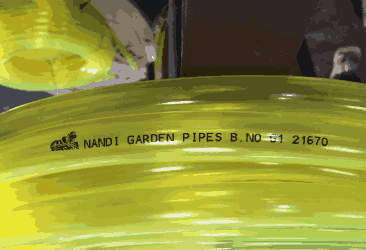

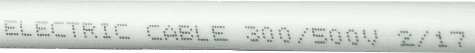

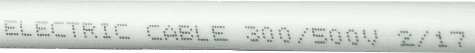

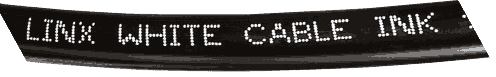

Linx inkjet coding and marking solutions explicitly cater to the extrusion industry for various applications. Moreover, these versatile printers allow easy mounting and mobility to accommodate different production line requirements. Indeed, making them ideal for marking a wide range of extruded products.

Standard extruded products that can benefit from inkjet coding and marking solutions include cable and wire, tubes, guttering, PVC pipes, panels, double-glazing window frames, molded parts, construction materials, industrial pipes and cables, connectors, aluminum profiles, metal elements, and rubber.

Importance of Coding and Marking Printers in the Extrusion Industry

Overall, Linx coders specialize in delivering high-quality prints at fast speeds, making them suitable for various coding requirements within the extrusion industry.

Coding and marking printers play a vital role in extruded materials’ identification, traceability, and compliance. Several types of printers are available for coding and marking extruded materials, each with unique advantages and limitations. When selecting a coding and marking printer for extruded materials, consider factors such as the type of material, production speed, required print quality and durability, and the complexity of the design. Each method has advantages and limitations, so choose the one that best fits your needs and requirements.

In addition to inkjet coding, laser coding options are also available, depending on the substrate material. Laser technology provides several benefits, including:

- Code longevity: Laser-marked codes do not degrade over time or during storage, ensuring long-lasting legibility.

- Variety of code sizes: Lasers can produce codes in various sizes to suit specific product and application requirements.

- No drying time: Since no involvement of ink, there is no need to wait for codes to dry, eliminating the risk of smudging.

Laser coding can be an excellent alternative option to print on specific substrates within the extrusion industry. When selecting a coding solution, consider factors such as substrate material, production speed, required print quality and durability, and the complexity of the design. Each method has advantages and limitations, so choose the one that best fits your needs and requirements.

Need help choosing a printer for extrusion applications?

There are several methods for printing and marking on cables, each with its own advantages and limitations. You can view all our coding solutions – Here

High-Speed Cable Marking Solutions

For high-speed production environments, choose a marking system specifically designed for fast production lines. These printers should be able to keep up with the speed of the production line while maintaining accurate and legible prints. Look for features like automatic printhead cleaning, low ink level alerts, and user-friendly software to ensure consistent print quality and minimize downtime.

When selecting a cable marking method, consider factors such as the cable material, production speed, required print quality and durability, and the complexity of the design. Each method has advantages and limitations, so choose the one that best fits your needs and requirements. Wire manufacturers prefer these fast inkjet coding and marking printers for mass production.

Find the best printer for your cable production – get in touch with us now

In the fast-paced beverage manufacturing industry, it’s imperative to have reliable and efficient printing solutions. That’s where Linx continuous inkjet printers and laser marking machines come in. With the ability to print on plastic and glass bottle caps, manufacturers opt for these printers gradually. Indeed, Linx printers offer an ideal solution for expiration dates and LOT codes. And with continuous printing capabilities from the top of the production line, there’s no need to slow down the process. So, whether you want to print expiry dates or etch intricate designs onto bottle caps, Linx has you covered.

In various industries, date/time and batch or lot numbers needs printing onto bottle caps instead of bottles or labels. But, as bottle caps present a challenge of small circumference and hard-to-code materials, finding an efficient solution can be difficult. Thankfully, with the right bottle coders, printing onto metal or plastic caps is possible and a breeze. Our bottle printing technology enables small character printing that is legible and readable throughout the product’s shelf life.

Inkjet Coder to Print on Bottle Cap

Inkjet coding is an efficient and precise way of printing information onto bottle caps. Whether it be expiry date, batch number, or QR codes. With the ability to continuous printing on fast-moving production lines, inkjet coders became crucial. Opting for solvent- or water-based inks depends entirely on the material and the desired print quality. The use of inkjet coders guarantees reliable and high-speed printing, ensuring that the production process runs smoothly and efficiently. As such, inkjet coding has become essential in the packaging industry.

Laser Marking Machine for Etching

Laser etching on bottle caps plays a vital role in the world of product labeling. The application of this technology makes it possible to accurately print or engrave expiry dates or LOT codes right onto the bottle cap itself. Unlike traditional printing methods, the laser etching process is non-contact and does not involve any ink. Indeed, the caps can last well beyond the life of the product. Bottle cap printing or etching is a reliable and cost-effective solution, especially for industries requiring strict adherence to regulatory guidelines. It ensures the protection of consumers by allowing manufacturers to keep track of their products lifespans and avoid potential hazards. Laser etching on bottle caps is an innovative and practical way to keep products safe, and consumers informed.

If You Would Like to Know More About Printing on Bottle Caps – Contact Us

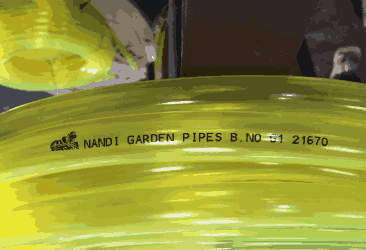

Continuous inkjet (CIJ) coding is a popular and effective method for printing on rubber items such as tubes, cables, gaskets, sleeves, and more. This non-contact printing method is suitable for high-speed production lines and can print directly on moving rubber products. Here are some critical considerations for CIJ coding and printing on rubber items:

Inkjet Coding on Rubber

- Choosing the correct ink:

Selecting the appropriate ink for inkjet coding on the rubber is crucial for ensuring proper adhesion and durability.

Some common types of inks used for printing on rubber include:

Solvent-based inks: These inks provide excellent adhesion on rubber surfaces and dry quickly. They are resistant to abrasion, moisture, and chemicals.

UV-curable inks: When exposed to UV light, these inks cure, forming a durable bond with the rubber surface. UV-curable inks are also resistant to environmental factors like moisture, heat, and abrasion.

Specialty inks: Some manufacturers may require specific ink formulations designed for their unique rubber materials or applications.

Continuous Inkjet Printing Solutions

- CIJ printer features:

Look for inkjet coding printers for rubber with features such as automatic printhead cleaning, low ink-level alerts, and user-friendly software for designing and editing printed information. These features will help ensure consistent print quality and minimize downtime during production. - Integration with production line:

The CIJ coding system should integrate identically with the existing production line, allowing for easy setup, operation, and maintenance. Also, Ensure that the printer can keep up with the speed of the production line and accurately print on moving rubber items. - Batch coding and branding:

Inkjet coding printers can be used to print batch codes, logos, barcodes, and other information directly on rubber products. This helps manufacturers track and trace their products, comply with regulations, and enhance their brand visibility. - Customization:

Work with an inkjet coding printer supplier who can provide customized solutions tailored to your specific rubber items, production line requirements, and desired print quality.

In conclusion, continuous inkjet coding is suitable for printing on moving rubber items such as tubes, cables, gaskets, sleeves, and more. By selecting the correct ink, ensuring proper integration with the production line, and choosing a printer with the necessary features, manufacturers can achieve high-quality, durable prints for batch coding and branding purposes.

Print expiry date on glass bottles using various methods, each with its advantages and limitations. You can view all our coding solutions – Here

When selecting a method for printing expiration dates on glass bottles, consider factors such as the production speed, required print quality and durability, and the complexity of the design. Each method has advantages and limitations, so choose the one that best fits your needs and requirements.

High-precision bottle expiry date printer

Get accurate and reliable glass bottle markings with our inkjet coding and laser marking printers.

Fast coding for bottling lines

Improve your beverage production with our high-speed inkjet and laser printers for expiry dates and batch codes.

Boost labeling efficiency

Maximize productivity with our cutting-edge inkjet coding and laser marking printers for glass bottle expiry date printing.

Printing expiry dates on flexible packaging is essential for ensuring product safety, compliance, and traceability. Several methods are available for printing expiry dates on flexible packaging, each with advantages and limitations. Here are some popular options:

- Continuous Inkjet (CIJ) Printer:

CIJ printers are widely used for printing expiry dates on flexible packaging because they can print directly on moving products on a production line. They offer high-quality, durable prints and can handle a variety of substrates, including flexible films and pouches. Choose an ink specifically designed for flexible packaging materials to ensure proper adhesion and durability. - Thermal Inkjet (TIJ) Printers:

TIJ printers use heat to eject ink droplets from nozzles onto the flexible packaging surface. They produce high-resolution prints and are suitable for applications requiring fine details or smaller text. TIJ printers work well for printing expiry dates on various flexible packaging materials, such as plastic films and laminates. Select an ink that is compatible with the specific flexible packaging material for optimal results. - Thermal Transfer Over Printer (TTO):

TTO printers use heat and pressure to transfer ink from a ribbon onto the flexible packaging surface. This method provides high-quality, durable prints and is particularly suitable for printing on thin films and labels used in flexible packaging. TTO printers offer excellent print resolution and can produce sharp, clear text, barcodes, and graphics.

Print Expiry Date on Packaging Films

When selecting a method for printing expiry dates on flexible packaging, consider factors such as the packaging material, production speed, required print quality and durability, and the complexity of the design. Each method has advantages and limitations, so choose the one that best fits your needs and requirements.

To ensure successful expiry date coding and marking on flexible packaging, follow these best practices:

- Choose the appropriate printer and ink/ribbon based on your packaging material and application requirements.

- Regularly maintain and clean the printer to ensure consistent print quality and prevent downtime.

- Test the adhesion, readability, and durability of the printed expiry date on the flexible packaging material before full-scale production.

- Implement a quality control system to monitor and verify the accuracy of the printed expiry dates throughout the production process.

Laser marking on paper packaging has become popular due to its precision, versatility, and eco-friendly nature. Here are some of the standard applications of laser marking on paper packaging:

- Barcodes and QR codes:

In the first place, Laser coders can create high-resolution barcodes and QR codes directly on the paper packaging. Also, it allows tracking and inventory management of the finished product. - Expiration dates and batch numbers:

Laser marking can easily print expiration dates coupled with batch numbers on the packaging. In fact, ensuring accurate and legible data for consumers and manufacturers. - Logo:

Lasers marking printers can also mark logos and branding elements on paper packaging. Moreover, it enhances product presentation and brand recognition. - Product information:

Laser coders can print detailed product information, instructions, or warnings on paper packaging. In particular, it ensures clear communication with the end users. - Serialization and unique identification:

Lasers can create unique serial numbers or identification codes on paper packaging for security, anti-counterfeiting, and traceability purposes. - Warning and Usage Instruction:

Laser marking machines can directly mark warning signs and usage instructions on paper packaging. Indeed, adding an aesthetic appeal to the product.

Advantages of Laser marking on paper packaging

- Non-contact method: Lasers marking machines do not physically touch the product surface, reducing the risk of damage or deformation to the packaging.

- High precision and resolution: Lasers can create highly accurate and detailed markings, even on small or complex designs.

- Fast processing speeds: Laser marking is suitable for high-speed production lines, ensuring efficient operations.

- Eco-friendly: Laser marking eliminates the need for inks, solvents, and other consumables, reducing waste and environmental impact.

In summary, laser marking on paper packaging provides a versatile and eco-friendly solution for creating various types of markings, including barcodes, expiration dates, logos, product information, and decorative designs. This technology offers high precision, fast processing speeds, and reduced environmental impact, making it an attractive option for manufacturers and packaging companies.

Need guidance selecting the right laser solution for paper packaging? Talk to our experts now.

When selecting a date coder for bakeries, it is important to choose one that is fast and efficient enough to keep up with high-volume production while ensuring accurate and legible printing. The date coder should also be easy to set up and operate to reduce downtime and minimize errors during the printing process. Additionally, some date coders come with software that allows customization of printing settings, such as font size and expiration date format, to meet the specific needs of the bakery.

Inkjet coding printers are widely used for wire marking to print essential information directly onto products. The information published on cables and wires may include:

- Manufacturer’s name or logo:

This helps identify the brand and enhances brand visibility. - Product identification:

Marking model numbers, part numbers, or product codes help customers and installers quickly identify the specific type of cable or wire. - Technical specifications:

Wire gauge, conductor count, insulation type, voltage rating, and temperature rating are often printed on cables and wires. Also, ensures proper usage and compliance with safety regulations. - Industry standards and certifications:

Printing relevant industry standards (e.g., UL, CE, RoHS) and certifications to make the cable meet specific quality. - Sequential markings:

Identically these wire marking printers can print in meters or feet. Which helps users accurately measure and cut cables and wires during installation. - Batch or lot numbers:

These numbers help manufacturers trace products back to their production batch. Furthermore, it allows for quality control and tracking purposes. - Production date or expiry date:

The production date indicates when the cable or wire was manufactured. This information helps ensure proper stock rotation and adherence to warranty terms. Hence wire marking printers play a vital role in the cable industry. - Barcodes or QR codes:

These machine-readable codes can additional information about the cable or wire, such as its origin, production details, or technical specifications. Scanning the code can provide quick access to this information for inventory management, quality control, or installation purposes.

Inkjet Wire Marking Printers

Wire marking printers are an essential tool in the world of manufacturing and production. Inkjet Coders can easily do the marking on wire and cable for identification purposes. Whether you are working in the telecommunications industry or automotive industry, that requires precise labeling of lines. An inkjet wire marking printer can help streamline your operations and reduce errors. With the ability to print text, barcodes, and even logos, these printers suit your specific needs. So if you’re looking for a cost-effective and reliable way to improve your wire marking process. Contact us Today!

In general, the Linx inks can print with ease on flexible packaging with an inkjet coding machine. Variety of inks and fluids depending on the material and application requirements. Here are some popular ink types:

Know more about our Inks – Here

- Solvent-based Inks:

CIJ printers and some TIJ printers commonly use solvent-based inks. These inks contain pigments or dyes dissolved in a solvent that evaporates quickly. Indeed, leaving behind durable and high-quality inkjet printing on flexible packaging materials. Solvent-based inks offer good adhesion, quick drying times, and resistance to chemicals and abrasion. - Water-based Inks:

Water-based inks are suitable for use with some TIJ printers and flexographic printing systems. These inks contain pigments or dyes suspended in a water-based solution, making them more environmentally friendly than solvent-based inks. Water-based inks work well on porous substrates, such as paper and uncoated flexible inkjet packaging materials. But may not adhere well to non-porous materials without surface treatment. - UV-curable Inks:

UV-LED inkjet printers use UV-curable inks and offer excellent adhesion, durability, and resistance to chemicals and abrasion. These inks contain photoinitiators that cure instantly when exposed to UV light. Additionally, creating high-quality inkjet coding on various flexible packaging materials, including plastic films and laminates. - Hot-melt Inks:

Thermal transfer over printers (TTO) uses hot-melt inks, also known as solid inks. Also, some drop-on-demand (DOD) inkjet printers use hot melt inks. These inks come in solid form, and the print head melts the ink during the printing. As a result, transferring it from a ribbon onto the flexible packaging material. Hot-melt inks offer good adhesion and durability, making them suitable for printing on thin films and labels.

When selecting the best ink for inkjet coder for printing flexible packaging printing, consider factors such as the printer type, packaging material, production speed, required print quality and durability, and environmental considerations. Each ink type has advantages and limitations, so choose the one that best fits your coding and marking requirements.

Buy the best inkjet coder for packaging!

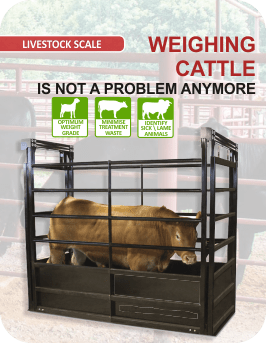

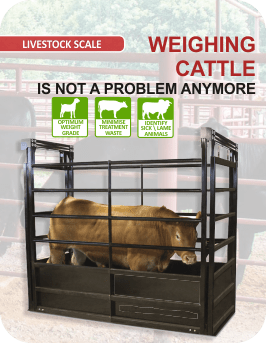

A cattle weighing scale is a specialized weighing device designed specifically for weighing cattle and other livestock animals. These scales play a crucial role in modern livestock management by providing accurate weight measurements. Moreover, it helps farmers make decisions about feeding, breeding, and overall herd health. Here’s an overview of the benefits and uses of cattle weighing scales:

Uses of Animal Weighing Scale

- Monitoring and Feeding Cattle Accurately:

Farmers can monitor their animal’s growth and development by regularly weighing cattle. This information helps them to analyze and adjust feeding programs. Which ensures each animal receives the appropriate amount based on weight, age, and production goals (e.g., meat, milk, or reproduction). Accurate feeding contributes to better feed conversion rates, cost savings, and ultimately increased profitability. - Identifying Sick Animals:

Regular weighing can help identify animals that are not gaining weight as expected or losing weight. In fact, you can quickly identify which animal indicates health issues or lameness. Early detection allows farmers to address these issues promptly. In addition, it minimizes the impact on the animal’s well-being and the herd’s overall productivity.

Advantages of Cattle and Animal Weighing Scale

- Optimum Weight Management:

Cattle weighing scales help farmers determine when their animals have reached the optimum weight for various purposes. Such as breeding, selling, or slaughtering of animals. This information ensures farmers can make well-informed decisions about the right time to sell or breed their cattle. Furthermore, it maximizes profits and maintains a healthy, productive herd. - Record Keeping and Performance Analysis:

Modern scales often come with data recording capabilities, allowing farmers to track each animal’s weight history. This data can be used to analyze the performance of individual animals and the entire herd. - Compliance and Traceability:

Accurate weight records are essential for meeting regulatory requirements related to animal welfare, traceability, and food safety. Cattle weighing scales help farmers maintain accurate documentation and demonstrate compliance with industry standards and regulations.

Cattle weighing scales come in various designs and configurations, including platform scales, alleyway scales, and weigh bars. When selecting a scale, consider factors such as the size of your herd, available space, portability requirements, and budget. Investing in a reliable and accurate scale is valuable for improving livestock management, animal welfare, and overall farm profitability.

Continuous Ink Jet Printer (CIJ) – High-speed, non-contact printing technology in time. Industries prefer these printers for coding and marking product and packaging information. It prints product data likewise, batch numbers, expiry dates, barcodes, QR codes, and logos on a wide range of materials.

Linx Global is a leading manufacturer of inkjet coding solutions and ink-jet printers. These printers are known for their ease of use and their need for very low maintenance. Linx CIJ best fits businesses looking to improve their coding and marking quality. View available coding & marking solutions here.

InkJet Coder for Printing Expiry Dates

- High-speed printing:

Linx continuous ink-jet printers can print easily despite fast-moving production lines and ensure minimal downtime. - Non-contact printing:

The CIJ technology allows non-contact printing with the substrate in detail. Indeed it enables coding on uneven surfaces and reduces the risk of damage. - Wide range of inks:

Linx offers a variety of ink types, such as food grade, pigmented, and special inks. - Easy setup and operation:

Continuous ink-jet printers feature provides not only user friendly access but also a quick change of ink systems. As a result, this makes them easy to set up, operate, and maintain. - Robust design:

Linx continuous inkjet printers can print in harsh environments coupled with sealed print heads to protect against dust and moisture. - Low maintenance:

CIJ printers require minimal maintenance with self cleaning print heads in effect. Also, it provides automatic diagnostics, ensuring optimum performance and reduced downtime. - Connectivity and integration:

Above all, These printers offer various connectivity options and can be easily integrated with existing production lines.

Overall, Investing in a Linx Global Continuous Ink-jet Printer can achieve clear coding and marking directly on your product.

The best printer for coding and marking on bottles depends on various factors. Such as the bottle material, production speed, required print quality, and durability. Discover our available coding solutions – here

Bottle Coding | Plastic & Glass Bottle Printing

Linx provides reliable and consistent bottle coding and marking solutions to minimize rework. Our printers and coders can easily integrate into production line systems, accommodating various line speeds. Automated date, time, code, and number series functions reduce manual interventions and avoid line downtime. We offer specialized coding solutions, such as UV visible inks and permanent laser marking, suitable for both luxury brands and anti-counterfeit product identification.

Our bottle coding printers are perfect for high volume expiration date coding or batch identification, as they can print directly onto plastic or glass bottles in almost any orientation and mark variable information, including barcodes and data matrix, and QR codes, and decrease waste and environmental impact. With profound experience in creating coding and marking equipment, we understand the unique challenges presented by printing on bottles, and our coding technologies have been specifically designed to meet them. Linx bottle coders are used across various industries, such as food, beverage, cosmetics, FMCG household products, pharmaceutical, and chemical bottling, and can help minimize production costs and improve rates.

Still unsure which coding method suits your needs? Talk to our experts

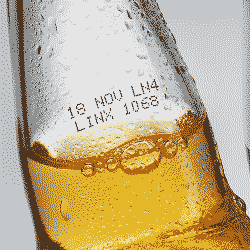

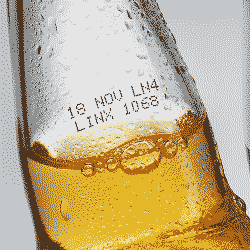

Efficiency is essential when it comes to bulk coding on glass bottles. This is where inkjet coding and laser marking come in. With the use of continuous inkjet technology, printing onto glass bottles can be done at lightning speed without sacrificing precision. On the other hand, inkless laser coding uses etching and engraving technology to create characters on the surface of the glass. Both methods are perfect for glass bottle coding. Moreover, it can print important information like expiry dates and batch codes, making it easy to keep up with production demands. When it comes to high-speed production lines, Linx printers are the perfect choice for accurate and efficient printing on glass bottles.

Continuous Inkjet (CIJ) Printers for Glass bottle coding

CIJ printers specialize in coding on glass bottles because they can print directly on moving products on a production line. They offer high-quality, durable prints and can handle the curved surfaces of glass bottles. Choose an ink specifically designed for glass surfaces to ensure proper adhesion and durability.

Thermal Inkjet (TIJ) Printers

TIJ coding printers use heat to eject ink droplets from nozzles onto the glass bottle surface. They produce high-resolution prints and are suitable for applications requiring fine details or smaller text. As with CIJ printers, select an ink that is compatible with glass surfaces for optimal results.

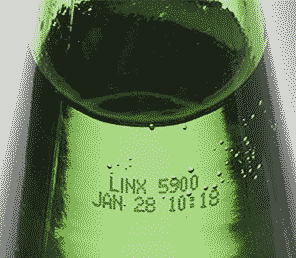

Laser Marking Machines

Laser marking is a non-contact method that uses a focused laser beam for coding on the surface of glass bottles. This method provides high precision and durability, making it ideal for marking expiration dates. CO2 or UV lasers specialize in marking on glass bottle surfaces. Indeed, they offer excellent contrast and minimal damage to the substrate. Linx fiber laser can quickly provide etching and engraving of character on glass bottles. Moreover, these printers specialize in coding at high-speed production lines.

Explore your options with our glass bottle coding experts.

Date coders for bakeries can use various printing technologies such as inkjet, thermal transfer, or laser. The choice of technology will depend on factors such as the type of packaging material and the desired level of detail. There are various printing methods available for printing expiry dates on baked goods, including inkjet, thermal transfer, and laser. Each method has its own advantages and disadvantages, and the best method will depend on factors such as the type of packaging used, the volume of production, and the desired level of detail.

Linx-pigmented inks offer a durable option for coding on plastic bottle. Moreover, these printers can print batch numbers and expiry dates on various colored plastics. Indeed specializes in polyethylene (PE or PET), polypropylene (PP or OPP), PVC, and Nylon. These inks maintain clarity for years, even when exposed to daylight.

Continuous Inkjet (CIJ) Printers for Coding on Plastic Bottles

CIJ printers became popular for coding on plastic bottles because they can print directly on moving products on a production line. They offer high-quality, durable prints and can handle curved surfaces of various bottle materials, including glass, plastic, and metal. CIJ printers are suitable for high-speed production lines.

Thermal Inkjet (TIJ) Printers

TIJ coding printers use heat to eject ink droplets from nozzles onto the plastic bottle surface. They produce high-resolution prints and are suitable for applications requiring fine details or smaller text. TIJ bottle coding printers work well on various materials and can provide high-quality codes even at lower production speeds.

Laser Marking Machines

Laser marking is a non-contact method that uses a focused laser beam for coding on plastic bottle. This method offers high precision, durability, and flexibility, making it ideal for marking logos, barcodes, and other intricate designs. Laser marking machines work well on both glass and plastic bottles.

Linx Inkjet coding solutions allow manufacturers to print on plastic bottles easily. Moreover, Linx CIJ is capable of printing multiple line characters at a high-speed production line. Inkjet printers have more preference over laser marking machines in the plastic bottle industry. Considering the aspect of plastic getting damaged over high-intensity of heating through laser. Most of industries prefer black ink coding on bottles as the standard color. But at Linx, we have a variety of ink and fluids for catering to all the needs of the industrial market.

It is important to ensure that expiry dates are printed legibly and in a prominent location on the baked good’s packaging, such as the front or back label. This helps consumers quickly identify the product’s expiration date and avoid consuming expired products. Additionally, regulatory agencies require bakeries to include expiry dates and other mandatory information on their products. Therefore, ensuring that the date coder being used complies with the relevant regulatory requirements is essential.