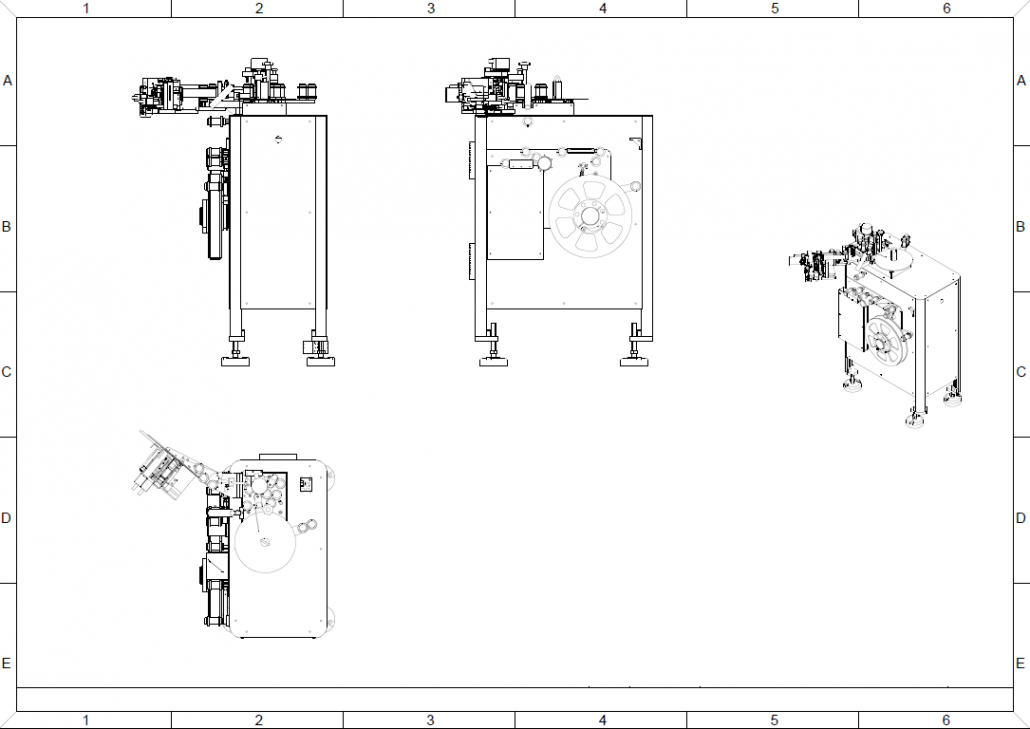

Product Diverting Station

The Product Diverting Station is a customized system designed to scan 1D/2D code, divert it to different conveyors, and apply 2D code labels on pre-defined product boxes.

Features

- Plug & Play System

- User-friendly Operation Panel

- Auto triggering system

- User-friendly Operating Panel & intuitive Menu Navigation

- Customized Illumination for glossy surfaces

- Ergonomic design as per Industrial Standards

- Robust 1D / 2D code algorithm to decode multiple codes in a single scan.

- Variable Speed Belt Conveyor with adjustable Side guide rod.

- Multiple High-resolution cameras suitable for decoding even 8 x 8 mm 2D codes for larger scan area

- State-of-the-art reflection-free illumination ensures multiple 1D / 2D code decoding over glossy surfaces.

- Designed to withstand tough production line environments.

- Improving production line up-time

- Quick product changeover

| Parameter | description |

|---|---|

| Product Diverting Station | • Camera – High resolution camera for 1D/2D/QR code scanning • Lens – A suitable high-resolution lens with minimum distortion is provided based on camera model. • Illumination – White LED, reflection free homogeneous illumination for reflective surface (inside plastic scanning) • Simultaneous scanning of diverted products for verification • Sensors (as applicable) • Ejector – Pneumatic pusher with rejection bin • Print and apply to label unit camera to inspect label 1D/2D/QR code • Traffic management system for jamming bundles |

| PC | • Processor Group – Intel Chipset High speed controller, above 2.2 GHz • Operating System – Windows 10 Pro • Memory Capacity – 4 GB • Storage Capacity – 120 GB SSD • Display Size – 15” or 17” • Operator interface – LED/LCD and touch screen |

| Embedded I/O controller with embedded software | • Camera – High resolution camera for 1D/2D/QR code scanning • Lens – A suitable high-resolution lens with minimum distortion is provided based on the camera model. • Illumination – White LED, reflection-free homogeneous illumination for reflective surface (inside plastic scanning) • Simultaneous scanning of diverted products for verification • Sensors (as applicable) • Ejector – Pneumatic pusher with rejection bin • Print and apply to label unit camera to inspect label 1D/2D/QR code • Traffic management system for jamming bundles |

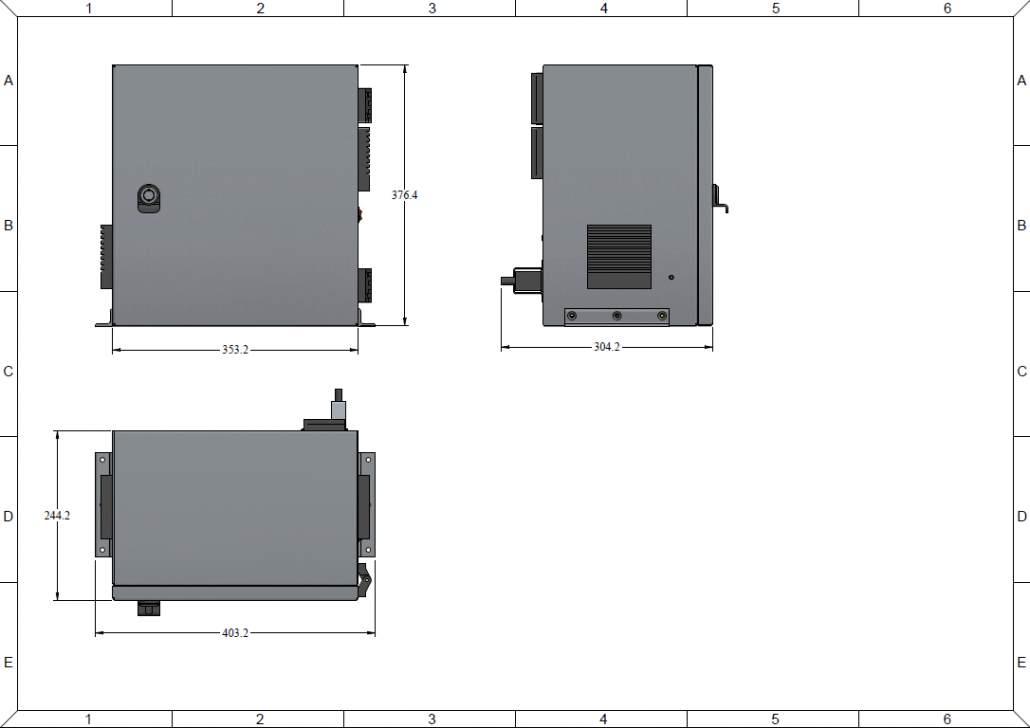

| Material of Construction | • Section frame, Structure, Plates – Aluminium • Covers – SS304 |

| External communications | • RS232, Ethernet, USB |

| Operating temperature | • 5°-40°C |

| Power supply | • 230 Volt AC, single phase with MCB for protection |