How to Print on Rubber Parts and Products?

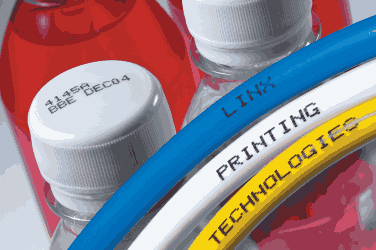

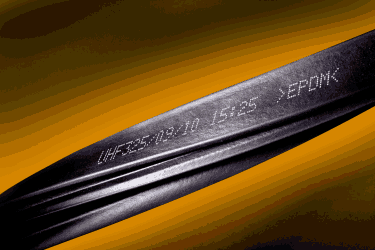

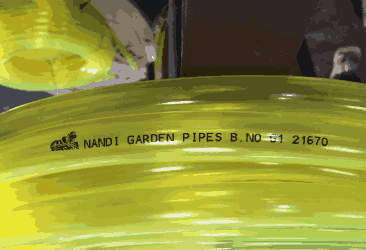

Continuous inkjet (CIJ) coding is a popular and effective method for printing on rubber items such as tubes, cables, gaskets, sleeves, and more. This non-contact printing method is suitable for high-speed production lines and can print directly on moving rubber products. Here are some critical considerations for CIJ coding and printing on rubber items:

Inkjet Coding on Rubber

- Choosing the correct ink:

Selecting the appropriate ink for inkjet coding on the rubber is crucial for ensuring proper adhesion and durability.

Some common types of inks used for printing on rubber include:

Solvent-based inks: These inks provide excellent adhesion on rubber surfaces and dry quickly. They are resistant to abrasion, moisture, and chemicals.

UV-curable inks: When exposed to UV light, these inks cure, forming a durable bond with the rubber surface. UV-curable inks are also resistant to environmental factors like moisture, heat, and abrasion.

Specialty inks: Some manufacturers may require specific ink formulations designed for their unique rubber materials or applications.

Continuous Inkjet Printing Solutions

- CIJ printer features:

Look for inkjet coding printers for rubber with features such as automatic printhead cleaning, low ink-level alerts, and user-friendly software for designing and editing printed information. These features will help ensure consistent print quality and minimize downtime during production. - Integration with production line:

The CIJ coding system should integrate identically with the existing production line, allowing for easy setup, operation, and maintenance. Also, Ensure that the printer can keep up with the speed of the production line and accurately print on moving rubber items. - Batch coding and branding:

Inkjet coding printers can be used to print batch codes, logos, barcodes, and other information directly on rubber products. This helps manufacturers track and trace their products, comply with regulations, and enhance their brand visibility. - Customization:

Work with an inkjet coding printer supplier who can provide customized solutions tailored to your specific rubber items, production line requirements, and desired print quality.

In conclusion, continuous inkjet coding is suitable for printing on moving rubber items such as tubes, cables, gaskets, sleeves, and more. By selecting the correct ink, ensuring proper integration with the production line, and choosing a printer with the necessary features, manufacturers can achieve high-quality, durable prints for batch coding and branding purposes.