Inkjet Coder for Rubber

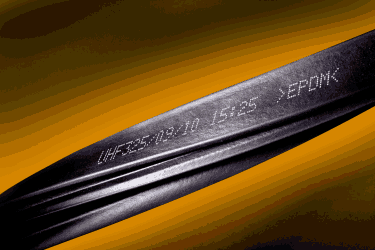

Rubber printing and plastic parts marking are essential processes that require various techniques for their execution. Inkjet coding and laser marking are the two primary methods for coding and marking on rubber and rubber parts. Laser cutting and engraving are particularly effective for marking rubber by leaving personalized messages or labels on rubber components. Tire marking requires a specific type of rubber coding that is resistant to water and temperature fluctuations. In contrast, coding on rubber sleeves, raw rubber treatments, and finished tires after vulcanization demands careful micro-printing to ensure they can withstand environmental stressors. Regardless of the application, accurately coding and marking rubber requires technical expertise and precision in inkjet coding and laser marking techniques.

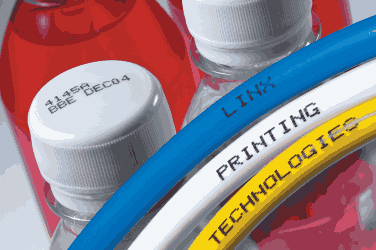

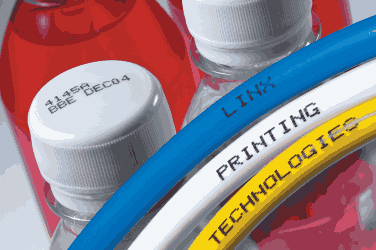

Fast Inkjet Coding on Rubber Products

Printing high opacity messages onto hard-to-code substances like rubber has always been challenging, but no more with specialized pigmented ink. The Linx 8900 from the continuous inkjet range is the perfect solution for quickly printing on rubber. The specialized pigmented inks used in this technology are specifically designed to adhere to rubber surfaces, producing long-lasting and apparent marks. These codes won’t fade or disappear even when exposed to harsh environmental conditions like heat and sunlight. From inkjet coding to laser marking, the possibilities are endless with this incredible technology.

Continuous Printing with Inkjet Coder for Rubber Industry

When it comes to coding and marking product identification information for industrial components and rubber substrates, Linx industrial coders are the ideal option. Featuring a range of available settings and accessories, these flexible and versatile coders are designed to integrate into existing production lines easily. Additionally, their IP-rated construction helps to keep dust and moisture contaminants out, ensuring reliable and efficient performance even in the most challenging conditions. For permanent coding options on rubber elements and products, laser markers are an excellent choice, while continuous inkjet printers offer a reliable alternative for coding onto rubber substrates in industries such as automotive and industrial components.

Related Products for Inkjet Coding and Laser Marking on Rubber

FAQ’s

Inkjet Coding and Marking Solutions

A continuous inkjet (CIJ) coding printer (non-contact printing technology) can quickly print high-quality codes, text, and graphics on various substrates. Food, beverage, pharmaceuticals, and packaging industries mostly use CIJ for marking batch numbers, expiry dates, and barcodes. Here’s an overview of how a CIJ coder works:

Continuous Inkjet Printer Workings

- Ink System:

The Continuous Inkjet printer has an ink system so that it can reserve ink. The ink, which typically contains solvents, dyes, or pigments, circulates continuously through the system. - Ink Pressure and Circulation:

CIJ pressurizes the ink and pumps it from the reservoir to the printhead. After passing through the printhead, CIJ collects the unused ink and returns it to the reservoir for recirculation. - Printhead and Nozzle:

The printhead contains a nozzle with a small opening, usually ranging from 40 to 70 microns in diameter. A piezoelectric crystal inside the nozzle vibrates at a specific frequency, typically between 60,000 and 120,000 times per second. - Droplet Formation:

As the pressurized ink enters the vibrating nozzle, it breaks into individual droplets due to the vibration effect. These CIJ droplets release in a continuous stream from the nozzle. - Charge Electrode:

Immediately after the droplets exit the nozzle, they pass through a charged electrode. The electrode imparts an electrostatic charge to each droplet, depending on the intended position of the printable character. - Deflection Plates:

The charged ink droplets travel through a pair of deflection plates, which create an electric field. Depending on the droplet charge with a more or less electric field, determining their position on the substrate. - Printing on the Substrate:

The accurately deflected CIJ droplets reach the substrate, creating the desired characters or graphics. Meanwhile, the non-deflected droplets fall into a gutter and return to the ink reservoir for recirculation. - Drying and Curing:

As the ink droplets land on the substrate, the solvents evaporate quickly, leaving behind the ink on the surface. This process results in a high-quality, permanent print that is resistant to smudging and fading.

Print with Food Grade Inks

The Continuous inkjet coder’s ability to print directly on moving products makes it an ideal choice for many industrial coding applications. Additionally, the technology offers high-speed printing, low maintenance requirements, and the capability to produce high-resolution prints with minimal downtime.

Expiry Date Printer

Continuous Inkjet Printers are popular for printing variable information, such as dates or batch codes during production. These printers explicitly handle products of different sizes, shapes, or textures, making them prime for many industries. Furthermore, Linx Printing Technologies offer a range of continuous inkjet printers that are cost-effective and efficient. Some features include remote printer monitoring and customer support, concealed and easy-to-clean printheads, error-free touch-screen control, and simple self-service capability. Compared to other industrial inkjet coders, Linx’s printers provide a reliable and quality solution to meet your needs.

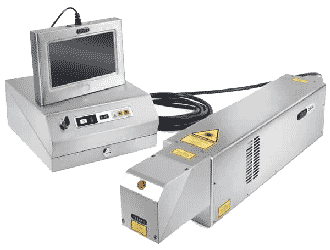

Linx 8900 Continuous Inkjet Printer (CIJ)

This printer delivers efficient output with the help of a remote application to keep you in control anytime and anywhere. Moreover, Linx CIJ allows you to print up to six lines, including barcodes, batch coding, and QR codes. Therefore it’s perfect for high-speed production, retail packaging, and 24/7 operations.

Linx 8900 inkjet coder has popularity because of its remote access, control, and support through the Linx PrinterNet. This allows for error-free coding by enhancing your monitoring and control capabilities. Additionally, it features a quick operation with a touchscreen interface, self-service, and minimal intervention to maximize production uptime. The Linx 8900 CIJ Printer allows you to print onto both primary and secondary packaging. Hence, one printer further makes your printing process easy.

Take your production to the next level with the Linx 8900 Continuous Inkjet Printer.

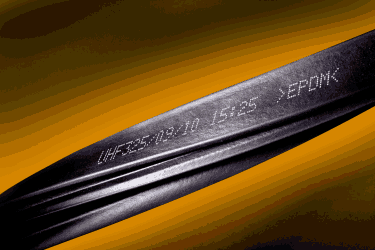

Laser marking suits the rubber industry, allowing direct etching and engraving messages on the product. The laser utilizes a focused beam of light to create high-contrast, precise, on the rubber surface. This process works well with various types of rubber, including natural rubber, synthetic rubber, and silicone.

Laser marking offers several advantages:

- High precision:

Fiber Laser provides highly detailed and accurate information, allowing for intricate designs, logos, barcodes, and text on rubber surfaces. - No contact:

Since laser marking results in a non-contact process, the rubber material has no physical wear. Also, it eliminates the need for consumables like ink and solvent. - Durability:

Laser marking rubber is resistant to abrasion, heat, chemicals, and UV exposure. Additionally, ensuring that the marks remain legible and intact throughout the product’s life. - Flexibility:

Fiber or CO2 Laser systems also have software programs to set different messages at variable speeds to print on rubber. - Speed and efficiency:

Laser rubber marking is fast, making it suitable for high-volume production environments.

Select the suitable laser type for laser marking on rubber, such as a CO2 or fiber laser. And adjust the parameters like power, speed, and frequency to achieve the desired result without damaging the printable material.

In conclusion, the laser is an effective and versatile method for the rubber industry. Manufacturers can achieve high-quality, durable, and precise printing of rubber products by selecting the right equipment.

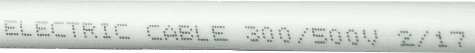

Continuous inkjet (CIJ) coding is a popular and effective method for printing on rubber items such as tubes, cables, gaskets, sleeves, and more. This non-contact printing method is suitable for high-speed production lines and can print directly on moving rubber products. Here are some critical considerations for CIJ coding and printing on rubber items:

Inkjet Coding on Rubber

- Choosing the correct ink:

Selecting the appropriate ink for inkjet coding on the rubber is crucial for ensuring proper adhesion and durability.

Some common types of inks used for printing on rubber include:

Solvent-based inks: These inks provide excellent adhesion on rubber surfaces and dry quickly. They are resistant to abrasion, moisture, and chemicals.

UV-curable inks: When exposed to UV light, these inks cure, forming a durable bond with the rubber surface. UV-curable inks are also resistant to environmental factors like moisture, heat, and abrasion.

Specialty inks: Some manufacturers may require specific ink formulations designed for their unique rubber materials or applications.

Continuous Inkjet Printing Solutions

- CIJ printer features:

Look for inkjet coding printers for rubber with features such as automatic printhead cleaning, low ink-level alerts, and user-friendly software for designing and editing printed information. These features will help ensure consistent print quality and minimize downtime during production. - Integration with production line:

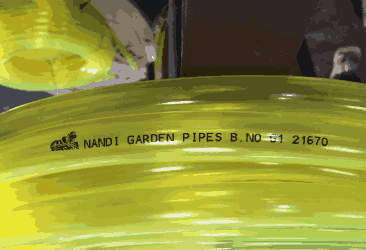

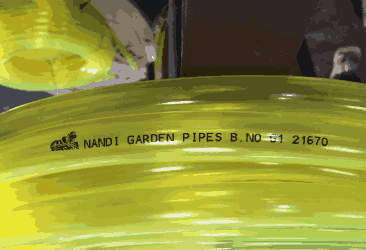

The CIJ coding system should integrate identically with the existing production line, allowing for easy setup, operation, and maintenance. Also, Ensure that the printer can keep up with the speed of the production line and accurately print on moving rubber items. - Batch coding and branding:

Inkjet coding printers can be used to print batch codes, logos, barcodes, and other information directly on rubber products. This helps manufacturers track and trace their products, comply with regulations, and enhance their brand visibility. - Customization:

Work with an inkjet coding printer supplier who can provide customized solutions tailored to your specific rubber items, production line requirements, and desired print quality.

In conclusion, continuous inkjet coding is suitable for printing on moving rubber items such as tubes, cables, gaskets, sleeves, and more. By selecting the correct ink, ensuring proper integration with the production line, and choosing a printer with the necessary features, manufacturers can achieve high-quality, durable prints for batch coding and branding purposes.

Continuous Ink Jet Printer

Continuous Ink Jet Printer (CIJ) – High-speed, non-contact printing technology in time. Industries prefer these printers for coding and marking product and packaging information. It prints product data likewise, batch numbers, expiry dates, barcodes, QR codes, and logos on a wide range of materials.

Linx Global is a leading manufacturer of inkjet coding solutions and ink-jet printers. These printers are known for their ease of use and their need for very low maintenance. Linx CIJ best fits businesses looking to improve their coding and marking quality.

Benefits of Linx Global CIJ Printers in detail:

InkJet Coder for Printing Expiry Dates

- High-speed printing:

Linx continuous ink-jet printers can print easily despite fast-moving production lines and ensure minimal downtime. - Non-contact printing:

The CIJ technology allows non-contact printing with the substrate in detail. Indeed it enables coding on uneven surfaces and reduces the risk of damage. - Wide range of inks:

Linx offers a variety of ink types, such as food grade, pigmented, and special inks. - Easy setup and operation:

Continuous ink-jet printers feature provides not only user friendly access but also a quick change of ink systems. As a result, this makes them easy to set up, operate, and maintain. - Robust design:

Linx continuous inkjet printers can print in harsh environments coupled with sealed print heads to protect against dust and moisture. - Low maintenance:

CIJ printers require minimal maintenance with self cleaning print heads in effect. Also, it provides automatic diagnostics, ensuring optimum performance and reduced downtime. - Connectivity and integration:

Above all, These printers offer various connectivity options and can be easily integrated with existing production lines.

Overall, Investing in a Linx Global Continuous Ink-jet Printer can achieve clear coding and marking directly on your product.