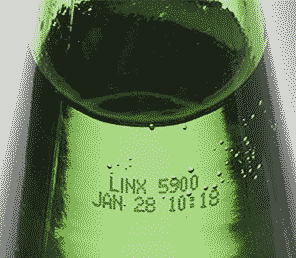

Inkjet coding on glass

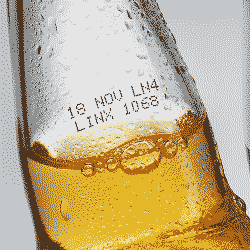

When it comes to glass bottles, ensure the printing of correct expiry or expiration dates. That’s where Linx CIJ and TIJ printers come in for inkjet coding on glass. With the proper inkjet coding and laser marking machine, glass bottles can print easy-to-read date codes directly onto their surfaces. This benefits manufacturer in terms of product traceability and reassures consumers that they are purchasing safe and fresh products. Whether marking the bottling or expiration date, inkjet coding on glass bottles provides the best result.

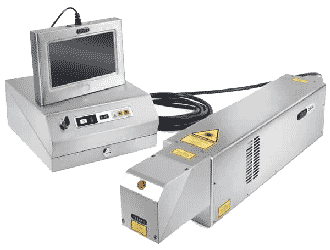

Linx Inkjet Coding and Laser Marking Printers

Linx Printing Technologies provide solutions for coding on both wet and dry glass, meeting permanent and erasable coding requirements. Our continuous inkjet printers boast UV inks suitable for anti-counterfeiting high-value goods. Inkjet coders can use specialized adhesive ink options, while laser coders etch directly onto glass surfaces. Our laser coders can do marking in extreme product environments and can scribe on both hot and cold glass. Selecting between inkjet and laser technology depends on the specific industry needs.

Fast Line Coding and Marking Solutions

Fast-line coding and marking on glass bottles became essential in the beverage industry. Also, high-speed production lines demand quick, accurate printing of expiry dates and lot numbers.

Linx Inkjet coding and Laser Marking Printer can handle all in all. High-speed inkjet or laser marking printers are suitable options for fast-line coding and marking on glass bottles. The choice of equipment will depend on factors such as production speed, desired print quality, and budget.

Related Products

Printing date codes, lot numbers, and other details on glass bottles and containers using inkjet coding and marking are possible. Inkjet coding and marking machines work with glass surfaces and instead produce high-quality, accurate prints.

A glass bottle date stamp or coding machine is an essential tool for manufacturers needing to print product information. These machines use inkjet technology to print expiry dates, batch codes, and barcodes directly onto the surface of the glass.

Inkjet coding and marking on glass bottles require food-grade ink that is safe for consumption and compliant with regulatory requirements. In the first place, make sure that the ink adheres to the glass’s surface. Moreover, it should remain legible throughout the product’s shelf life and resist fading, smudging, or rubbing off.

In conclusion, inkjet coding and marking on glass bottles and containers is a fast, efficient, and cost-effective solution.

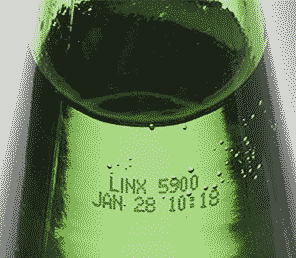

Laser marking and etching for printing expiry dates and LOT codes on glass bottles. Here are some important considerations when using laser marking and etching on glass bottles:

- Choosing the suitable laser: Different types of lasers are available for laser marking and etching, including CO2 and fiber lasers. The choice of laser will depend on the material, printable information, and line speed.

- Legibility: Laser marking and etching should produce legible and clear prints that remain visible throughout the shelf life. This helps to ensure that consumers can quickly identify the product’s expiry date and LOT code.

- Durability: Laser marking and etching should be durable and resistant to environmental factors such as moisture, heat, and abrasion. This ensures that the information remains accurate and legible throughout the product’s shelf life.

- Compliance: Regulatory agencies require manufacturers to label their products with expiry dates and LOT codes to ensure food safety. Laser marking and etching should comply with these regulations to avoid fines or penalties.

- Efficiency: Laser marking and etching are fast and efficient methods of printing information on glass bottles. This helps to reduce production time and costs and increase productivity.

In conclusion, laser marking and etching are effective methods of printing expiry dates and LOT codes on glass bottles.

In the fast-paced beverage manufacturing industry, it’s imperative to have reliable and efficient printing solutions. That’s where Linx continuous inkjet printers and laser marking machines come in. With the ability to print on plastic and glass bottle caps, manufacturers opt for these printers gradually. Indeed, Linx printers offer an ideal solution for expiration dates and LOT codes. And with continuous printing capabilities from the top of the production line, there’s no need to slow down the process. So, whether you want to print expiry dates or etch intricate designs onto bottle caps, Linx has you covered.

In various industries, date/time and batch or lot numbers needs printing onto bottle caps instead of bottles or labels. But, as bottle caps present a challenge of small circumference and hard-to-code materials, finding an efficient solution can be difficult. Thankfully, with the right bottle coders, printing onto metal or plastic caps is possible and a breeze. Our bottle printing technology enables small character printing that is legible and readable throughout the product’s shelf life.

Inkjet Coder to Print on Bottle Cap

Inkjet coding is an efficient and precise way of printing information onto bottle caps. Whether it be expiry date, batch number, or QR codes. With the ability to continuous printing on fast-moving production lines, inkjet coders became crucial. Opting for solvent- or water-based inks depends entirely on the material and the desired print quality. The use of inkjet coders guarantees reliable and high-speed printing, ensuring that the production process runs smoothly and efficiently. As such, inkjet coding has become essential in the packaging industry.

Laser Marking Machine for Etching

Laser etching on bottle caps plays a vital role in the world of product labeling. The application of this technology makes it possible to accurately print or engrave expiry dates or LOT codes right onto the bottle cap itself. Unlike traditional printing methods, the laser etching process is non-contact and does not involve any ink. Indeed, the caps can last well beyond the life of the product. Bottle cap printing or etching is a reliable and cost-effective solution, especially for industries requiring strict adherence to regulatory guidelines. It ensures the protection of consumers by allowing manufacturers to keep track of their products lifespans and avoid potential hazards. Laser etching on bottle caps is an innovative and practical way to keep products safe, and consumers informed.

If You Would Like to Know More About Printing on Bottle Caps – Contact Us

If you’re wondering how to print an expiry date on glass bottles, a few options are available. Date coding and batch coding on beverage glasses can be done easily done using two types of printing technologies: continuous inkjet printers and laser coders. Choosing the right product technology depends on factors such as the color of the substrate, production environment, and line speed. For example, if you need to print on clear glass bottles, laser coding may be a better option as it provides high-contrast printing that stands out. On the other hand, if your production speed is higher and you’re printing on darker glass bottles, continuous inkjet printers may be a better choice, as they can handle faster line speeds and provide legible codes. Ultimately, understanding your specific needs will help you make the right choice regarding bottle coding on glass.

When selecting a method for printing expiration dates on glass bottles, consider factors such as the production speed, required print quality and durability, and the complexity of the design. Print expiry date on glass bottles using various methods, each with its advantages and limitations. You can view all our coding solutions – Here

High-precision bottle expiry date printer

Get accurate and reliable glass bottle markings with our inkjet coding and laser marking printers.

Fast coding for bottling lines

Improve your beverage production with our high-speed inkjet and laser printers for expiry dates and batch codes.

Boost labeling efficiency

Maximize productivity with our cutting-edge inkjet coding and laser marking printers for glass bottle expiry date printing.

The best printer for coding and marking on bottles depends on various factors. Such as the bottle material, production speed, required print quality, and durability. Discover our available coding solutions – here

Bottle Coding | Plastic & Glass Bottle Printing

Linx provides reliable and consistent bottle coding and marking solutions to minimize rework. Our printers and coders can easily integrate into production line systems, accommodating various line speeds. Automated date, time, code, and number series functions reduce manual interventions and avoid line downtime. We offer specialized coding solutions, such as UV visible inks and permanent laser marking, suitable for both luxury brands and anti-counterfeit product identification.

Our bottle coding printers are perfect for high volume expiration date coding or batch identification, as they can print directly onto plastic or glass bottles in almost any orientation and mark variable information, including barcodes and data matrix, and QR codes, and decrease waste and environmental impact. With profound experience in creating coding and marking equipment, we understand the unique challenges presented by printing on bottles, and our coding technologies have been specifically designed to meet them. Linx bottle coders are used across various industries, such as food, beverage, cosmetics, FMCG household products, pharmaceutical, and chemical bottling, and can help minimize production costs and improve rates.

Still unsure which coding method suits your needs? Talk to our experts

Efficiency is essential when it comes to bulk coding on glass bottles. This is where inkjet coding and laser marking come in. With the use of continuous inkjet technology, printing onto glass bottles can be done at lightning speed without sacrificing precision. On the other hand, inkless laser coding uses etching and engraving technology to create characters on the surface of the glass. Both methods are perfect for glass bottle coding. Moreover, it can print important information like expiry dates and batch codes, making it easy to keep up with production demands. When it comes to high-speed production lines, Linx printers are the perfect choice for accurate and efficient printing on glass bottles.

Continuous Inkjet (CIJ) Printers for Glass bottle coding

CIJ printers specialize in coding on glass bottles because they can print directly on moving products on a production line. They offer high-quality, durable prints and can handle the curved surfaces of glass bottles. Choose an ink specifically designed for glass surfaces to ensure proper adhesion and durability.

Thermal Inkjet (TIJ) Printers

TIJ coding printers use heat to eject ink droplets from nozzles onto the glass bottle surface. They produce high-resolution prints and are suitable for applications requiring fine details or smaller text. As with CIJ printers, select an ink that is compatible with glass surfaces for optimal results.

Laser Marking Machines

Laser marking is a non-contact method that uses a focused laser beam for coding on the surface of glass bottles. This method provides high precision and durability, making it ideal for marking expiration dates. CO2 or UV lasers specialize in marking on glass bottle surfaces. Indeed, they offer excellent contrast and minimal damage to the substrate. Linx fiber laser can quickly provide etching and engraving of character on glass bottles. Moreover, these printers specialize in coding at high-speed production lines.

Explore your options with our glass bottle coding experts.

As a manufacturer or distributor of beverages, ensuring product safety and quality is the top priority. One way you can enhance the visibility of your product information is by imprinting best-before dates or batch codes on the bottles or cans. Where to print these codes, however, can be a concern. That’s where our coders come in, offering complete flexibility in printing options. From the curved surface of the bottle to the bottom and even the cap, our inkjet coder for the beverage can print the required information per your specific needs. With our state-of-the-art technology, you can rest assured that your products are correctly labeled and ready to go to market.

Linx-pigmented inks offer a durable option for coding on plastic bottle. Moreover, these printers can print batch numbers and expiry dates on various colored plastics. Indeed specializes in polyethylene (PE or PET), polypropylene (PP or OPP), PVC, and Nylon. These inks maintain clarity for years, even when exposed to daylight.

Continuous Inkjet (CIJ) Printers for Coding on Plastic Bottles

CIJ printers became popular for coding on plastic bottles because they can print directly on moving products on a production line. They offer high-quality, durable prints and can handle curved surfaces of various bottle materials, including glass, plastic, and metal. CIJ printers are suitable for high-speed production lines.

Thermal Inkjet (TIJ) Printers

TIJ coding printers use heat to eject ink droplets from nozzles onto the plastic bottle surface. They produce high-resolution prints and are suitable for applications requiring fine details or smaller text. TIJ bottle coding printers work well on various materials and can provide high-quality codes even at lower production speeds.

Laser Marking Machines

Laser marking is a non-contact method that uses a focused laser beam for coding on plastic bottle. This method offers high precision, durability, and flexibility, making it ideal for marking logos, barcodes, and other intricate designs. Laser marking machines work well on both glass and plastic bottles.

Linx Inkjet coding solutions allow manufacturers to print on plastic bottles easily. Moreover, Linx CIJ is capable of printing multiple line characters at a high-speed production line. Inkjet printers have more preference over laser marking machines in the plastic bottle industry. Considering the aspect of plastic getting damaged over high-intensity of heating through laser. Most of industries prefer black ink coding on bottles as the standard color. But at Linx, we have a variety of ink and fluids for catering to all the needs of the industrial market.