Inkjet coding on glass

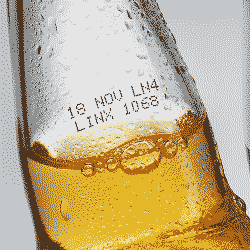

When it comes to glass bottles, ensure the printing of correct expiry or expiration dates. That’s where Linx CIJ and TIJ printers come in for inkjet coding on glass. With the proper inkjet coding and laser marking machine, glass bottles can print easy-to-read date codes directly onto their surfaces. This benefits manufacturer in terms of product traceability and reassures consumers that they are purchasing safe and fresh products. Whether marking the bottling or expiration date, inkjet coding on glass bottles provides the best result.

Linx Inkjet Coding and Laser Marking Printers

Linx Printing Technologies provide solutions for coding on both wet and dry glass, meeting permanent and erasable coding requirements. Our continuous inkjet printers boast UV inks suitable for anti-counterfeiting high-value goods. Inkjet coders can use specialized adhesive ink options, while laser coders etch directly onto glass surfaces. Our laser coders can do marking in extreme product environments and can scribe on both hot and cold glass. Selecting between inkjet and laser technology depends on the specific industry needs.

Fast Line Coding and Marking Solutions

Fast-line coding and marking on glass bottles became essential in the beverage industry. Also, high-speed production lines demand quick, accurate printing of expiry dates and lot numbers.

Linx Inkjet coding and Laser Marking Printer can handle all in all. High-speed inkjet or laser marking printers are suitable options for fast-line coding and marking on glass bottles. The choice of equipment will depend on factors such as production speed, desired print quality, and budget.

Related Products – For Inkjet Coding and Laser Marking on Glass

Can you print directly on glass bottles?

Printing date codes, lot numbers, and other details on glass bottles and containers using inkjet coding and marking are possible. Inkjet coding and marking machines work with glass surfaces and instead produce high-quality, accurate prints.

A glass bottle date stamp or coding machine is an essential tool for manufacturers needing to print product information. These machines use inkjet technology to print expiry dates, batch codes, and barcodes directly onto the surface of the glass.

Inkjet coding and marking on glass bottles require food-grade ink that is safe for consumption and compliant with regulatory requirements. In the first place, make sure that the ink adheres to the glass’s surface. Moreover, it should remain legible throughout the product’s shelf life and resist fading, smudging, or rubbing off.

In conclusion, inkjet coding and marking on glass bottles and containers is a fast, efficient, and cost-effective solution.

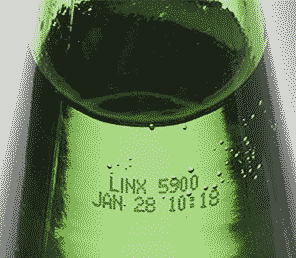

Laser Marking and Etching on Glass

Laser marking and etching for printing expiry dates and LOT codes on glass bottles. Here are some important considerations when using laser marking and etching on glass bottles:

- Choosing the suitable laser: Different types of lasers are available for laser marking and etching, including CO2 and fiber lasers. The choice of laser will depend on the material, printable information, and line speed.

- Legibility: Laser marking and etching should produce legible and clear prints that remain visible throughout the shelf life. This helps to ensure that consumers can quickly identify the product’s expiry date and LOT code.

- Durability: Laser marking and etching should be durable and resistant to environmental factors such as moisture, heat, and abrasion. This ensures that the information remains accurate and legible throughout the product’s shelf life.

- Compliance: Regulatory agencies require manufacturers to label their products with expiry dates and LOT codes to ensure food safety. Laser marking and etching should comply with these regulations to avoid fines or penalties.

- Efficiency: Laser marking and etching are fast and efficient methods of printing information on glass bottles. This helps to reduce production time and costs and increase productivity.

In conclusion, laser marking and etching are effective methods of printing expiry dates and LOT codes on glass bottles.