Inkjet Coding on Bakery Goods

As the food industry continues to experience growth, the demand for inkjet date coders has increased worldwide. Inkjet coding and marking have become essential for primary packaging in the bakery industry. Indeed, these inkjet coding printers help to ensure accurate labeling and coding for baked goods is crucial. Moreover, it can explicitly print expiry dates, barcodes, QR codes, and other information on the packaging. Additionally, the accuracy of the ink droplets makes the printer information very clear and legible to avoid any errors. Linx Printing Technology UK offers three innovative technologies for inkjet coding on bakery goods. With their innovative solutions, bakeries can ensure they meet the regulatory requirements and provide accurate information to their customers.

Inkjet Coding on Cereals, Flour, and Breads

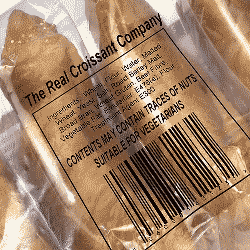

Inkjet coding has become vital in the food packaging industry, especially regarding cereals, flour, and bread. Providing consumers with clear and concise product information has never been more crucial. Inkjet printing allows manufacturers to label their products with unique identification codes. This includes expiry dates, barcodes, and batch numbers, ensuring consumers know what they purchase. The technology is fast, efficient, and can print on various materials, including paper, board, and plastic. Furthermore, it provides manufacturers with flexibility and customization options. Enabling them to adjust their messaging and labeling needs as the market demands.

Printing Expiry Date on Baked Goods

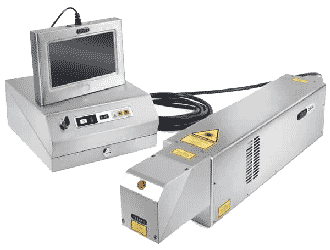

The baked goods industry deals with various packaging materials and dusty production environments. Hence, the baked goods industry faces unique challenges in coding and marking. A reliable industrial coder is essential in ensuring accuracy and efficiency here. Especially on fast-moving production lines where there is little room for error. This is where Linx coding solutions come in, with their easy-to-use interface. In fact, Linx printers are the perfect choice for inkjet coding and marking on baked goods. They provide legible and durable prints, crucial for maintaining product traceability and compliance with industry standards. So, if you’re looking for a dependable coding solution for your bakery, look no further than Linx.

Inkjet Date Coder for Baked Products

Packaging requirements in the baking industry are extensive and varied, as the sector encompasses an extensive range of products that includes sugar-free and gluten-free options. In order to keep track of these items and ensure their freshness and quality, there is a need for a reliable and efficient date coding solution for bakery items. Automatic date coding machines are a viable option that can be used to code Julian dates, barcodes, QR codes, and even graphics on all types of packaging material. Linx offers a vast range of coding options that can enhance your productivity and print quality codes, helping you keep your bakery items in top condition for longer. Whether you are a small bakery or a large-scale operation, Linx has the solutions to meet your needs.

Related Products

FAQs – related to Inkjet Coding on Bakery Goods

Printing Expiry Date on Baked Goods

Printing expiry dates on baked goods is crucial to ensuring food safety and regulatory compliance. Here are some critical considerations for printing expiry dates on baked goods:

- Choosing the correct ink: When printing expiry dates on baked goods, it is essential to use food-grade ink that is safe for consumption and compliant with regulatory requirements. Food-grade inks are designed to withstand baking and ensure the printed information remains legible and accurate.

- Selecting the appropriate printing method: There are various printing methods available for printing expiry dates on baked goods, including inkjet, thermal transfer, and laser. Each method has its own advantages and disadvantages, and the best method will depend on factors such as the type of packaging used, the volume of production, and the desired level of detail.

- Ensuring accurate and legible printing: The expiry date should be printed legibly and in a prominent location on the baked good’s packaging, such as the front or back label. This helps to ensure that consumers can quickly identify the product’s expiration date and avoid consuming expired products.

- Meeting regulatory requirements: Regulatory authorities require food manufacturers to include expiry dates on their products as part of food safety regulations. Therefore, it is essential to comply with these regulations to avoid fines or penalties and ensure that products are safe for consumption.

Printing expiry dates on baked goods is crucial to ensuring food safety and regulatory compliance. Food manufacturers can provide consumers with safe and high-quality baked goods by using food-grade ink, selecting the appropriate printing method, ensuring accurate and legible printing, and complying with regulatory requirements.

Date Coder for Bakery

A date coder for bakeries is an essential piece of equipment that allows bakeries to print expiry dates, batch codes, and other important information on their products. Here are some considerations when choosing a date coder for a bakery:

- Type of printing technology: Date coders for bakeries can use various printing technologies such as inkjet, thermal transfer, or laser. The choice of technology will depend on factors such as the type of packaging material and the desired level of detail.

- Speed and efficiency: Date coders for bakeries should be fast and efficient to keep up with high-volume production. Look for a machine that can print at high speeds while ensuring accurate and legible printing.

- Ease of use: A date coder should be easy to set up and operate. This will help to reduce downtime and minimize the risk of errors during the printing process.

- Flexibility: Some date coders for bakeries come with software that allows for the customization of printing settings. This can include font size, expiration date format, and other details that are specific to the bakery’s needs.

- Compliance: Regulatory agencies require bakeries to include expiry dates and other mandatory information on their products. Therefore, ensuring that the date coder being used complies with the relevant regulatory requirements is essential.

In summary, a date coder for bakeries is essential for printing important information on baked goods. When choosing a date coder, consider factors such as printing technology, speed and efficiency, ease of use, flexibility, and regulatory compliance. By selecting the suitable date coder, bakeries can ensure that their products are accurately labeled, compliant with regulatory requirements, and safe for consumption.