Weighing Scales for Static and Dynamic Operations

When it comes to industries that require precise measurements. Our equipment is engineered to deliver likewise accurate results, No matter the size of the items. Overall we offer a range of options to meet your specific needs. Which includes both dynamic and static weighing equipment. Whether you need to weigh items in motion or for industrial processes. Furthermore, we have the complete weighing solution under one roof. Above all, you can trust us to provide reliable and effective weighing equipment. In view of learning more about our Industrial Solutions, visit our website today.

Hopper Scale

A hopper weighing scale with strain gauge load cells is a specialized weighing system designed for accurately measuring and dosing bulk materials in batch processes. The system consists of a hopper, strain gauge load cells, and a control unit that work together to ensure precise and efficient batching. Here's an overview of how a hopper scale for weighing with strain gauge load cells functions:

Batching and Dosing of Material

- Hopper:

The hopper holds the bulk material for weighing and dosing in time. It comes in various sizes and shapes depending on the application and material handling. Hoppers consist of vibrating or screw feeders to facilitate the controlled discharge of material. - Strain Gauge Load Cells:

These weighing sensors convert the pressure the hopper material exerts into an electrical signal. Identically, Load cell mounting is beneath the hopper scale. Which supports the weight and measuring of the content in the same way. - Control Unit:

The weighing indicator receives the electrical signals from the load cells and equally converts them into weight values. It monitors and controls the filling and discharging processes in time. Moreover, ensuring the dosing of the correct material amount for each batch. - Dosing Process:

The hopper is manually or automatically filled with the material through a conveyor or pneumatic system. The control unit continuously monitors the weight of the material in the hopper scale, comparing it to the pre-set target weight for each batch. Once it reaches the target weight, the control unit stops filling. - Discharge and Batching:

After reaching the target weight, the hopper discharges the weighed material into a mixing or processing unit or another container for further processing. The control unit manages the discharge process, releasing the entire batch before resetting the system for the next batch. - Data Recording and Reporting:

Many hoppers weighing systems can record batch data, including each batch's weight, time, and date. Hopper scales became essential for inventory management and compliance with industry regulations.

Load Balance with the help of a Strain Gauge

A hopper weighing scale with strain gauge load cells offers an efficient and accurate solution for dosing and batching bulk materials in various industries, including food processing, pharmaceuticals, chemicals, and agriculture. Automating and streamlining the batching process, these systems help improve productivity, reduce waste, and ensure consistent product quality.

Weighbridge and Weighing Equipment Suppliers in the UAE

Looking for reliable and accurate weighing equipment in the UAE, look no further than the experienced team at our Weighbridge and Weighing Equipment Suppliers. Our team is dedicated to providing our customers with the best products and services, whether you are in the market for a weighbridge for heavy-duty vehicles or a high-precision laboratory scale. Mainly we offer a wide range of products and solutions to meet your needs. Moreover, our knowledgeable staff can always provide expert advice and support. Chiefly with our commitment to quality and customer satisfaction. For this reason, you can trust us to help you find the perfect weighing equipment to suit your needs.

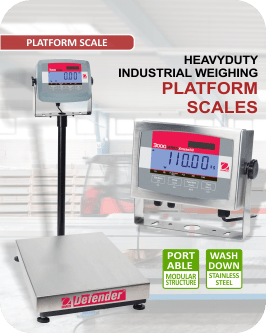

Platform Weighing Scales for Manufacturing Industry

Important to realize that the large & heavy-duty platform scale is the industry’s need. As a result, it provides precise and efficient weighing of heavy-duty objects. This scale is designed to provide accurate weighing in kilograms and tons, making it a highly reliable tool for any industrial setting. Indeed its high-quality load cell ensures fast and linear weights, eliminating the need for manual calculations. The scale base is designed to be paired with a weight indicator, allowing for even more accurate readings. Whether you need to weigh machinery, industrial equipment, or any other large commercial item, the platform scale is the perfect solution. In the first place, keep the object on the scale and let it do the rest. The platform, coupled with loadcells, forms a platform weighing scale. Looking for precision and reliability in your industrial or commercial weighing needs? Contact Us Now

| Length | Width | Width* | Capacity | Load Cells |

|---|---|---|---|---|

| 500 mm | 400 mm | 600 mm | 60 kg to 150 kg | 1 |

| 600 mm | 600 mm | 800 mm | 300 kg to 500 kg | 1 |

| 800 mm | 800 mm | – | 1000 kg | 4 |

| 1000 mm | 1000 mm | – | 1000 kg to 1200 kg | 4 |

| 1200 mm | 1200 mm | – | 2000 kg | 4 |

| 1500 mm | 1500 mm | 2000 mm | 3000 kg to 5000 kg | 4 |

Retail Price Computing Scale Specialized for Supermarket

Price computing scales are an essential part of any retail as well as commercial business. These specialized weighing machines calculate not only the weight of an item but also the price based on that weight. This versatile technology is also available in 15 kg and 30 kg capacities. Especially for supermarkets, grocery stores, and vegetable fruit markets. The ability to input the price of individual products for sale ensures accuracy and consistency in transactions, while built-in receipt printers make for easy record-keeping. Additionally, weigh price labeling retail scales offer a sleek and professional solution for labeling and pricing products. Invest in a price computing scale today to streamline your business operations and improve your bottom line.

Check Weigher for Weighing in Motion

Accuracy and consistency are equally crucial in product weight. Despite it cannot be overstated for any production line, and that’s where a check weigher comes into play. Instead, the end-of-line machine is the ultimate solution for dynamic weight measuring. Weighing components coupled with a conveyor belt and roller to weigh and handle bulk products on production lines. Moreover, with its ability to automatically check for correct weight, the check weigher ensures the highest level of weighing accuracy. Designed to fit the importance of the product while it is moving on the manufacturing line, it rejects under-filled or over-filled packages without interruption. With this check weigher system, the weight of the products can be checked while they are in motion, leaving any products that are over or under the set weight. It is a fully automatic solution for quality control, which saves time and money by preventing any discrepancies in production.

Pallet Truck Weighing Scale

Pallet weighing scales, or pallet jack scales, are vital to weight-handling equipment. These hydraulic pump-powered scales are designed to lift and weigh heavy pallets and boxes, and their impressive capacities range from 2000 kg to 4000 kg. What makes these scales so unique is their portability and ease of use. Transporting products to a weighing scale is no longer necessary, as these scales can seamlessly verify the weight at the exact location, saving time and effort. The accuracy of these scales ensures that customers receive dependable, trustworthy results every time.

Crane Scale for Industrial Application

When it comes to weighing heavier items, there is no tool more efficient than an industrial heavy-duty electronic crane scale. With its five digits super high light LED display and high-resolution hanging scale for loads up to 5-ton, 10-ton, and 15-ton, this tool is perfect for various applications such as shipping and receiving, industrial manufacturing, commercial fishing, and quality testing. The crane scale is usually hung to a mechanized crane and controlled remotely, making it both safe and convenient. With its exceptional division solution and precision, a crane scale is an indispensable tool for professionals who require an accurate and reliable weighing system.

Dimensional Scales for Measuring Volume and Weight Together

Shipping packages and parcels can be tricky for businesses trying to manage costs while providing reliable service. That’s why a dimensional scale has become a vital tool for the shipping industry. By determining shipping prices based on a package’s length, width, and height, these specialized logistics scales provide a simple, fast, accurate, and affordable solution to calculating shipping costs. The scales create reliable parcel condition records, measuring the weight and volume of packages, which is particularly useful for determining the weight and volume of properly shaped packages and pallets. As items are placed on these volume-measuring scales, the scale measures the dimensions of the box and gives its volume. This static volume and weighing measurements efficiently and precisely determine an object’s volume weight. Regarding shipping, it’s all about finding the right balance between accuracy and affordability, and the dimensional scale is a crucial tool for achieving that goal.

Horse or Equine Weighing Scale

Horse weighing scales have become an essential tool for horse owners worldwide. As a professional in the equine industry, you know that monitoring your horse’s health is of the utmost importance. That’s why investing in a reliable horse weighing scale is a must. With stainless steel load cells and a waterproof IP rating, this transportable scale can efficiently and accurately gather essential information on your horse’s weight. Designed specifically for the safe and reliable weighing of horses or large animals, this equine scale will help you to know precisely what your equine stock weighs, ensuring you feed them the right amount. Don’t leave your horse’s health to chance; invest in a horse weighing scale today.

Airport Luggage Scale for Weighing Baggage

When traveling by air, baggage weight can be stressful for many people. Excess baggage charges or the dreaded task of repacking luggage at the airport are not the most excellent way to start your much-anticipated journey. Fortunately, there is a solution: luggage scales. Specifically designed for the airport environment, these electronic scales can weigh bags up to 150 kg, with a division of 100 g. Passengers can easily adjust their luggage weight on the bench or floor scales prior to check-in. Say goodbye to stress and travel with confidence, knowing that you can weigh your luggage fast and efficiently with a reliable luggage scale.

Weighing Indicator for Weight Display

As industries continue to seek more precise ways of measuring weight, weighbridge indicators have become vital components for manufacturing and logistics. Tabletop and panel weighing indicators are two of the most common options, offering unique features and performance capabilities. Tabletop weighing indicators are compact and easy to use. On the other hand, we also have panel weighbridge indicators designed for more complex weighing tasks. Also, it features larger displays and advanced connectivity options. Whichever type of weighing indicator your business requires, investing in this technology can improve your accuracy, efficiency, and profitability.

Loadcell – Weighing Transducers for Platform

Load cells are highly precise weighing transducer’s most important weighbridge component that plays a vital role in many industries. The physical force of an object converts into a measurable electrical signal with the help of a load cell. We recommend using compression-type load cells in applications where the vertical load is applicable. In contrast, tensile-type load cells measure forces involved in horizontal order. Most of them choose shear beam load cells for industrial applications because they handle many loads. With their accuracy and reliability, load cells have become essential in food processing, pharmaceuticals, and manufacturing industries.