Automatic Scanning Station 1

Automatic Scanning Station 1

Automatic Scanning Machine

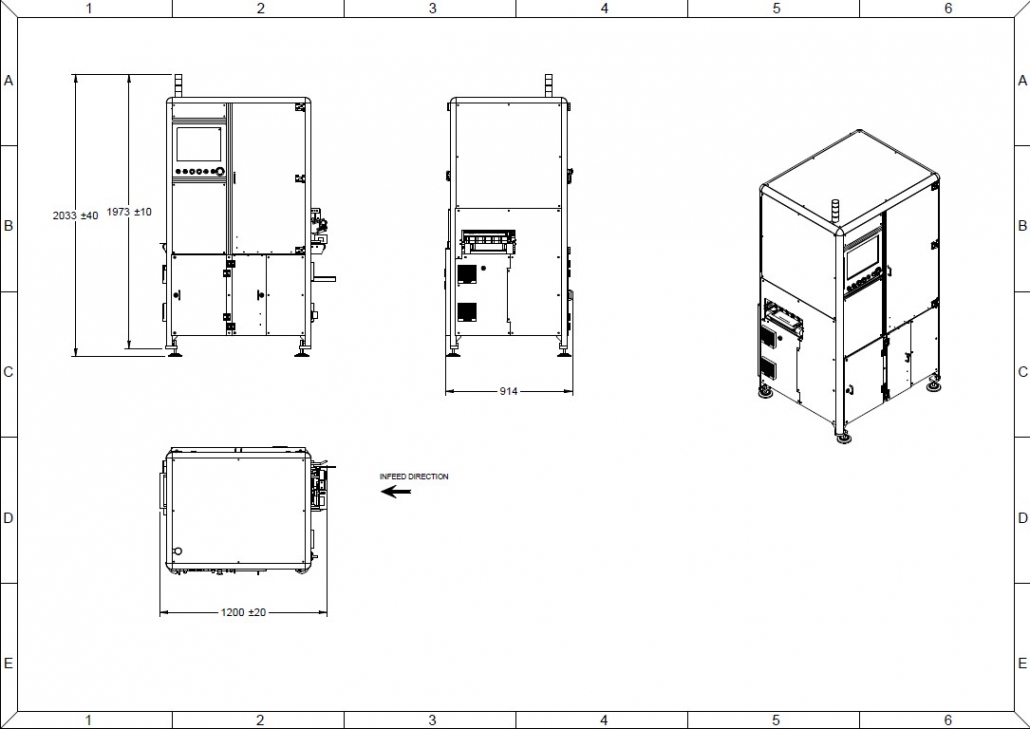

The Automatic Scanning Machine is specially designed for Online scanning of 1D/2D code present on the side of the box and in line with the Existing Conveyor System.

Designed to facilitate overall more productive operation with simple maintenance.

Features

- Plug & Play System

- User-friendly Operation Panel

- High-speed 1D/2D code Scanning Algorithm

- A vibration-free belt conveyor with a rejection bin. Polycarbonate enclosure.

- Traffic management maintains a gap between consecutive boxes, which reduces rejection and rework.

- Mirrorless multiple-resolution smart cameras with customized optics

- Robust 1D/2D code reading algorithm, which ensures minimum false rejection.

- State-of-the-art reflection-free illumination for more accurate shrink pack 1D/2D code decoding.

- Innovative design to accommodate the print and apply equipment within the machine.

- High-resolution camera to scan and verify the 2D Code on the box label.

- Integrated software can communicate with multiple cameras in the system.

- If the 1D/2D code is not scanned, the system does not apply the label on the Box. This avoids label wastage.

- Label roll changeover without stoppage of the production line.

- Various interlocks like rejection verification, rejection bin full, low air pressure, door open, etc.

| Parameter | description |

|---|---|

| Automatic Scanning Machine | • Camera - High resolution camera for box code scanning • Lens – Suitable high-resolution lens with minimum distortion is provided based on camera model. • Illumination - White LED, reflection free homogeneous illumination for reflective surface (inside plastic scanning) • Audible & Visual alarm • Sensors (as applicable) – Object, Target, Label detection, rejection verification sensor and rejection bin full sensor • Ejector -Pneumatic pusher with rejection bin • Conveyor with Traffic management to maintain gap and avoid jamming. • Print and apply labelling unit camera to inspect label 1D/2D /QR Code |

| PC | • Processor Group - Intel Chipset High speed controller, above 2.2 GHz • Operating System – Windows 10 Pro • Memory Capacity - 4 GB • Storage Capacity - 120 GB SSD • Display Size – 15” or 17” • Operator interface – LED/LCD and touch screen |

| Embedded I/O controller with embedded software | • I/O Controller – Processing & Controlling hardware signal and communicating with software, this controller integrates with sensor, electrical/electronic parts. • Camera communication • I/O Communication • Solid State Relay card • Required cables |

| Material of Construction | • Section frame, Structure, Plates – Aluminium • Covers – SS304 |

| External communications | • RS232, Ethernet, USB |

| Operating temperature | • 5°-40°C |

| Power supply | • 230 Volt AC, single phase with MCB for protection |