How to print and mark on extrusions?

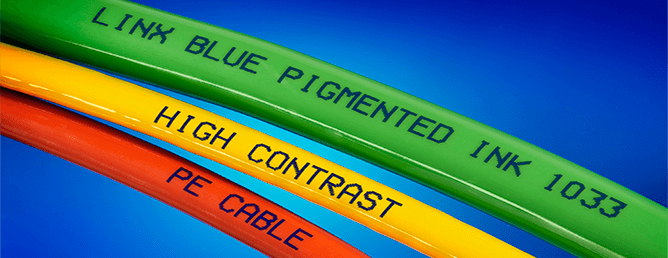

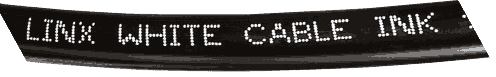

Linx inkjet coding and marking solutions explicitly cater to the extrusion industry for various applications. Moreover, these versatile printers allow easy mounting and mobility to accommodate different production line requirements. Indeed, making them ideal for marking a wide range of extruded products.

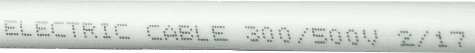

Standard extruded products that can benefit from inkjet coding and marking solutions include cable and wire, tubes, guttering, PVC pipes, panels, double-glazing window frames, molded parts, construction materials, industrial pipes and cables, connectors, aluminum profiles, metal elements, and rubber.

Importance of Coding and Marking Printers in the Extrusion Industry

Overall, Linx coders specialize in delivering high-quality prints at fast speeds, making them suitable for various coding requirements within the extrusion industry.

Coding and marking printers play a vital role in extruded materials’ identification, traceability, and compliance. Several types of printers are available for coding and marking extruded materials, each with unique advantages and limitations. When selecting a coding and marking printer for extruded materials, consider factors such as the type of material, production speed, required print quality and durability, and the complexity of the design. Each method has advantages and limitations, so choose the one that best fits your needs and requirements.

In addition to inkjet coding, laser coding options are also available, depending on the substrate material. Laser technology provides several benefits, including:

- Code longevity: Laser-marked codes do not degrade over time or during storage, ensuring long-lasting legibility.

- Variety of code sizes: Lasers can produce codes in various sizes to suit specific product and application requirements.

- No drying time: Since no involvement of ink, there is no need to wait for codes to dry, eliminating the risk of smudging.

Laser coding can be an excellent alternative option to print on specific substrates within the extrusion industry. When selecting a coding solution, consider factors such as substrate material, production speed, required print quality and durability, and the complexity of the design. Each method has advantages and limitations, so choose the one that best fits your needs and requirements.

Need help choosing a printer for extrusion applications?