Tank Calibration

Tank calibration is calibrating a tank to measure the amount of liquid stored within it accurately. This process involves measuring and adjusting several factors such as size, shape, capacity, output flow rate, pressure level, and temperature in order to obtain the most accurate measurement.

The first step in tank calibration is to determine the total capacity of a tank can weigh. The engineers and standard calibration methods should do full-capacity loading. After the initial measurement of the scale, one should adjust the scale for other factors that can influence the accuracy of measures taken from a tank. Like outside temperature changes due to weak insulation. On the contrary, changes inside the tank are due to variations in certain substances, such as solids and liquids inside the container.

Depending on their specific purpose and type, tanks may also need additional setup steps. Set up steps such as applying vacuum levels or pressurization for storage at various pressure zones within them. In the first place, accounting for other factors depends on what exact readings it needs. From simple measurements like volume to complex metrics like predicting how much energy/power will spill out when opening/closing valves within them.

Factors affecting Calibration of Tank Scale

Calculate the scale’s uncertainty on the completion of the measurement of all the factors. Or even energy emitted during transfer processes if needed (this could involve fundamental principles like Archimedes’ principle). The results then need validation against certified standards set forth by regulatory bodies, which guarantee accuracy through repeatable tests involving comparison with reference equipment prior to approval use across industrial settings where safety requirements are paramount.

In conclusion – Tank Calibration is an extensive process that requires numerous measurements both externally + internally, lots of mathematical calculations & algorithms, and validated testing before they can pass the quality assurance checkpoints necessary before actual implementation in real-world scenarios.

Tank calibration services are essential in accurately measuring and verifying quantities and volumes stored in ample fuel, chemical, and petroleum tanks. Moreover, we use Accredited tank and hopper scales calibration methods to ensure accuracy and traceability. A qualified technician uses certified test weights to apply the recommended load amount to the scale. Calibrating tanks correctly can help avoid costly errors and inaccuracies, ensuring a reliable and efficient fuel or chemical storage system. They then provide that the scale indicator displays the correct amount of weight, assuring that the tanks’ contents show accurate importance.

Tanks mostly have a mounting bracket for hanging test weight and should appropriately select the load cell capacity and accuracy. Tanks mostly have a mounting bracket for hanging test weight and should properly determine the load cell capacity and accuracy. It is essential to protect tank and hopper systems from extreme temperatures, moisture, vibration, and corrosive substances, and not always practical to apply weights to the total capacity.

Hopper Scale Calibration

Hoppers are an essential tool for any industry that needs to process solid materials. As square or rectangular containers with an open top, they allow for effortless loading of powders and granules. Whether it’s dispensing materials or collecting ingredients for later processing, hoppers can always be relied upon.

However, it is crucial to ensure that the hopper is calibrated correctly to ensure the accuracy of the weighing systems. This process, called hopper scale calibration, guarantees that the correct amount of materials is being dispensed or collected. Without proper calibration, inaccuracies in measurements can lead to inconsistent results and waste. Therefore, any industry that uses hoppers must prioritize hopper scale calibration to guarantee quality and efficiency in their operations.

Silo Calibration

When it comes to silos, proper calibration is essential. A silo is a closed container for storing granular or powdered materials. The accuracy of the silo’s measurements can have a direct impact on the quality of the final product. That’s why calibrating the silo is vital. Calibration ensures that the measurements are accurate and consistent so that suitable material reaches the processing plant. In short, a well-calibrated silo is crucial in ensuring that the processing plant can deliver products of the highest quality.

Reference Standard for Tank Scale Calibration

When it comes to tank calibration requirements, reference standards, and reference equipment are essential to ensure accurate measurements. One important aspect of reference equipment is using test weights, such as F1, F2, M1, and M3. In-house methods based on EURAMET/cg-18 v.4 and HB44-2018 provide a solid foundation for calibration procedures, but having the appropriate apparatus on hand is also essential. This includes a weighing indicator calibration manual, test weights, and a thermo-hygrometer. By utilizing these tools in conjunction with reference standards, achieving precise tank calibration results is possible.

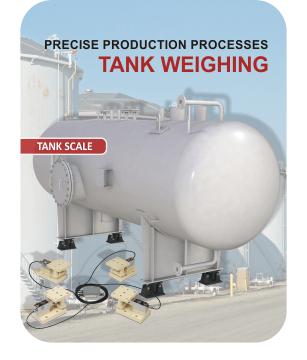

Tank Weighing Scale Calibration

Tank weighing calibration is the process of verifying the accuracy and performance of tank-mounted scales. It involves calibrating a tank’s weight to ensure it has been configured and operated correctly and that its readings are reliable. This type of calibration plays an essential role in commercial activities where accurate measurement is imperative, such as in manufacturing, logistics, or chemical production.

When a tank-mounted scale needs to be calibrated, a calibrated test weight will typically be used, usually placed inside the tank itself. The device must be installed by qualified personnel according to manufacturer specifications; otherwise, the measurements may not be accurate or reliable. Once the installation is complete and any necessary tests have been conducted on-site (including temperature checks), then it’s time for calibration.

This is achieved first by setting up a null balance point which requires adjusting all parameters (temperature, humidity, etc.) until total system stability has been reached. Then parameters can be adjusted further if necessary before taking actual readings from the scale during this period of time so as to calibrate it correctly according to best practice guidelines set out by national weights & measure authorities such as NIST (National Institute for Standards & Technology) in America and ISO/IEC 17025:2017 calibration standards throughout Europe & elsewhere around the globe for consistent results globally speaking wherever Tank Weighing Calibration takes place – making sure that each piece of equipment delivers optimum performance with maximum accuracy at all times.

Necessity of Tank Scale Calibration

If you want accurate readings from your tank scale, it’s important to calibrate it properly. To do this, you’ll need to start by making sure that the scale is free from any load and zeroing the weighing indicator by pressing the zero key. Then, you can place the test weights on the scale and check the reading against the minimum weight requirements listed in Table 1. Depending on the scale capacity, you’ll need to use a minimum of 12.5% capacity or 500 Kg, 25% or 150 Kg, or 100% of the weight. Once you’ve checked the reading, remove the test weights from the tank scale and check the zero indication. If it’s not zero, carry out a zero adjustment. After that, repeat the process of placing the test weights, checking the reading, and removing the weights until you get the required readings. Following these steps ensures that your tank scale is calibrated correctly and provides accurate measurements.

Frequency of Calibration for Tank Scales

Weighing tanks are essential tools for a wide variety of industries, including manufacturing, logistics, and food production. Therefore, it is crucial to ensure that these tanks are maintained in calibration at all times. Calibration involves adjusting the tank’s weight-measuring device to display the correct weight measurement at all times accurate.

The frequency of calibrating weighing tanks varies based on different factors, such as environmental conditions and rate of usage. Generally speaking, calibration should be done no less than once annually but can depend on the specifics of each situation; often, more frequent calibration may be necessary.

Some general guidelines include:

For high-accurate loads (0.1% or better), valves should be calibrated every six months or sooner depending on load stability and accuracy demands

For regular higher capacity applications (0.2% or better), valves must be calibrated every 12 months

Tanks used in harsh environments like high temperatures should also have their scales recalibrated more often than average—at least 3 – 4 times a year, depending upon local regulations.

Significant changes applied to scales must follow with immediate recalibration efforts.

In addition to regular calibration checks and maintenance schedules, operators need to pay attention to signs that indicate scale failure before starting any weighing operations—this includes measuring unusual readings even when using known weights during periodic tests on a day-to-day basis. This can help operators identify faults before they start significant operations, which will further reduce errors from incorrect measurements leading to improved performance & efficiency as valid results play an essential role in decision-making processes in many businesses today.

Steps for Calibration of Tanks Scale

Before starting any tank calibration, it is essential to inspect the hopper scale, tank scale, or silo and its surroundings. This step is crucial to ensure accurate and reliable calibration results. You should ensure the scale and its surroundings are clean, and the platform is not touching any sidewalls or foreign materials. It is essential to check that the scale is in perfect condition for calibration. You should also carefully inspect the test weights used for calibration and ensure they are free from physical damage and foreign material. The standard weights should be placed near the scale and left for sufficient time to reach thermal equilibrium. Finally, the thermo-hygrometer should be placed near the scale to measure the ambient temperature and humidity. All scale and weighing indicator details must be recorded in the worksheet, including the make, model, serial number, scale capacity or ranges, resolution, and location. This step prior to tank calibration is crucial in ensuring accurate and reliable measurements.

Authorized Calibration Personnel

Tank weighing calibration is essential for verifying the accuracy and reliability of a tank’s weight measurement. It should be performed by a qualified professional who understands the technical aspects of tank weighing. Before selecting someone to do this task, ensure they have experience working with tanks and understand the requirements for proper calibration.

When selecting someone to perform tank weighing calibration, several key factors should be considered:

1) Experience – This type of work requires technical expertise and knowledge, so selecting someone with relevant experience in this area is essential. It’s best to look for technicians who have been certified or explicitly trained in tank weighing calibrations.

2) Accuracy – The technician you choose must be able to accurately measure each part’s weight and verify any changes made during installation or service work.

3) Equipment – The technician must also access appropriate tools and equipment, such as pressure gauges, dynamometers, scales, etc., so accurate readings can be taken throughout the process.

4) Qualification & certification – Any technician performing this kind of work should possess valid qualifications

In summary, tank weighing calibrations require experienced professionals with relevant qualifications and certifications and access to all necessary equipment, including pressure gauges, scanners, dynamometers, and more; thus ensuring your tanks remain safe from potential leaks caused by lackadaisical inspection processes!

Repeatability of Tank Scale

Regarding the accuracy of tank scales, repeatability tests are essential. A repeatability test involves using standard test weights placed on the scale to determine consistency in weighing measurements. The process involves taking readings from the scale and recording them after each weight is placed and removed.

To ensure accurate results, it is essential to check the zero indication of the scale and calibrate it accordingly. This process should be repeated multiple times to ensure consistency, typically three times and all values should be recorded. By performing a repeatability test of the tank scale, you can have confidence in the accuracy of your scale measurements.

Linearity and Hysterisis of Tank Scale

To ensure accurate measurements and reliable data, performing a linearity and hysteresis test on a tank scale using a minimum of 5 points within the weighing range is crucial. The first point should be at or near zero, while the final point should be at or close to the maximum working capacity. Before beginning the test, it’s essential to record the zero indication of the scale with no load on it. To reach 25% of the scale capacity, one should place test weights on the scale and remove them while recording the reading. After removing the weights, add sufficient materials or liquids to the load-receiving element to duplicate the indication obtained with the test weight. This new reading will be considered a known test load, which can be used in further testing processes. By performing this test, you can ensure reliable and precise measurements for all your tank scale operations.

When testing the accuracy of a tank scale, a linearity test is crucial to ensure that the readings of the scale are consistent throughout its entire capacity range. To conduct this test, you must gradually add test weights until the scale reaches 25%, 50%, 75%, and finally, 100% of its capacity. Record the readings at each interval to assess the linearity of the scale. Another critical factor is the hysteresis test, which checks if the scale readings vary when you remove the weights. To do this, gradually remove the weights from the total capacity of the scale and record the readings at 75%, 50%, and 25% of the scale capacity. Finally, remove all weights from the scale and check the zero indication to ensure that it reads accurately. Running linearity and hysteresis tests will give you the confidence that your tank scale is accurately weighing.