Inkjet coding on snack foods

In the snack food industry, accurate coding and marking on the packaging is of utmost importance. Similarly, coding and marking printers cater to the market’s growing demand for producing high-quality, fast-drying ink and inkjet coding. Indeed, these inkjet coders became necessary with the increasing variety of sales promotions and packaging sizes. In addition, to resolve the risk of coding errors that can be time-consuming and costly, Inkjet coders stand upfront. Hence, reliable and fast coding solutions have become more critical than ever. Also, Linx solutions for batch coding on snack food help manufacturers with the secondary packaging. In fact, the snack food industry has seen growth in the usage of automatic spray inkjet coding machines for date code print. Moreover, these advanced machines speed up the process and offer flexibility, accuracy, and precision. Additionally, inkjet coding printer help manufacturers code accurately and consistently.

Overall, inkjet date coding is fast, efficient, and cost-effective for printing important information onto snack food products. By selecting the correct ink and setting up the printer correctly. Snack food manufacturers can ensure that their products have accurate information printed as per the regulatory requirements.

Snack food inkjet coding printer

The snack food industry has undergone significant changes in recent years, leading to a greater focus on packaging. Today, pre-packaged snacks come complete with a list of ingredients, batch codes, manufacturing, and best-before dates. And it’s not just primary packaging that’s important – codes and messages on secondary packaging like boxes are crucial too. Investing in a reliable coder with high-quality inkjet coding and marking capabilities is essential to avoid downtime.

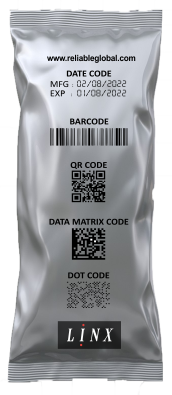

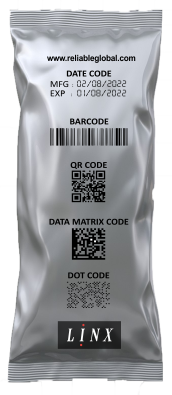

Inkjet Date Coder for Snack Packages

In the snack food industry, inkjet coding and marking have become essential to production. Large-character printers can save the cost of customized pre-printed boxes and print large messages, including barcodes and graphics. It’s not just about cost savings. Printing traceability information is crucial to keep track of the product path, abide by legislation, and prevent fines. This is where Linx batch coding on snack food solutions comes in. Their low maintenance, error-free, and quality codes allow them to print on both primary and secondary packaging. Indeed this makes them an ideal solution for the fast-paced snack food industry. Moreover, our continuous inkjet coders or laser coders are the preferred option for fast printing. Also, our thermal transfer-over printer can print a large number of messages onto flexible substrates like packaging films and plastics. As a result, ensure your snack food batch coding goes accurately and efficiently.

Related Products

FAQ’s

Inkjet Date Coder

In today’s fast-paced world, it’s more important than ever for snack food companies to track their products. Inkjet date coding has become an increasingly popular choice for snack food manufacturers. As it offers several benefits over traditional marking methods. Not only fast coding techniques, but these inkjet coders also allow for greater flexibility and customization. Additionally, inkjet coding is more environmentally friendly and cost-effective than other marking methods. Which makes it an ideal choice for snack food companies looking to improve their bottom line.

Working Process of Inkjet Date Coding

Inkjet date coding has become popular in the food industry to print expiration dates and lot numbers.

Here’s how it works:

Preparation: First, the snack food product preparation by ensuring it is clean and dry. This ensures that the ink adheres to the surface of the product correctly.

Ink selection: Second, a compatible ink selection based on the substrate (surface) of the product. Food-grade inks can ensure that the ink is safe for consumption and meets regulatory requirements.

Set up: Third, set up the inkjet printer with the appropriate ink and the desired information in the printer software. This can include expiration dates, lot numbers, barcodes, and other important information.

Printing: Forth, Once the printer setup is completed, it uses a high-pressure system to spray tiny droplets of ink onto the surface of the snack food product. This creates the desired text or image on the product, which consumers and other stakeholders can easily read.

This helps to differentiate products and create brand recognition among consumers.

Thermal Inkjet Coding and Marking on Snack Food Packaging

Thermal marking is a popular method for printing information on snack food products.

Here are some benefits of using inkjet date coder for a snack on snack food products:

High-resolution printing: Thermal marking produces high-resolution images and text, making it ideal for minor characters and fine detail. This ensures that critical information, such as expiration dates, lot numbers, and barcodes, are legible to consumers and stakeholders.

Permanent marking: Thermal markings are permanent and resistant to smudging, fading, or rubbing off. This ensures the information remains visible and accurate throughout the product’s shelf life.

Cost-effective: Compared to other marking methods, thermal marking is cost-effective for printing large quantities of snack food products. This automation process can print at high speeds, reducing labor costs and increasing efficiency.

Versatile: Thermal marking for different types of materials and surfaces, including plastic, metal, and paper packaging. This makes it a versatile option for snack food man various use a variety of materials in their packaging.

Environmentally friendly: Thermal marking does not require ink or other consumables, reducing waste and environmental impact.

In summary, using thermal marking on snack food products offers several benefits. Which includes high-resolution printing, permanent marking, cost-effectiveness, versatility, and environmental friendliness. By selecting the proper marking method, snack food manufacturers ensure their products have accurate labeled information. In fact, it also enhances their brand recognition and customer satisfaction.

Tips and Tricks for Inkjet Coding on Snack Food Products

When it comes to snack food products, a crucial aspect is the marking of the packaging. Inkjet and thermal marking are two popular methods used by manufacturers for this purpose. However, achieving the desired results requires some tips and tricks. For inkjet marking, choosing the correct ink is essential and ensuring that the printer settings are correctly configured. On the other hand, thermal marking requires preheating the substrate and adjusting the printing speed. Additionally, it’s best to use high-quality thermal transfer ribbons and test prints on sample products before mass production. These are just a few of the best inkjet and thermal marking tips and tricks that can help snack food manufacturers produce packaging that stands out and conveys essential information to consumers.