READY MEAL INDUSTRY

With cold/humid and washdown environments ready meals and frozen industries have high production demands from coding machines. In these fast-paced lines, with extreme production conditions, it is essential to have a robust coder that prevents downtime and improves efficiency.

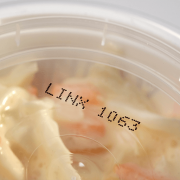

The Linx coders are IP rated and prevent the ingress of dust and moisture. The right choice of industrial coder thus becomes critical. With an expanding range of packaging, from plastic films to cartons to meet consumer requirements, a coder should be versatile and customizable.

The Linx coders are widely used in major food industries because of their ease to use, quality output, and versatility. Linx coders can improve your Overall Equipment Effectiveness (OEE) by maximizing efficiency and increasing your production uptime.

The Linx inkjet coders are user friendly and allow message creation and edition with ease. Easy to store and retrieve messages helps move coders between production likes if required. Specialized inks can adhere to various packaging in various production environments. Linx coders also give the flexibility to print messages in any orientation as per production needs. To know more about Special Adherence Inks, view datasheet.

RELATED PRODUCTS

Food Industry | Ready Meal | Printing on Frozen Food | Print on Ready Meals | Print mfg and expiry on ready meals | Plastic Material | Date coding on frozen food | Best before date | Expiry Date | Manufacturing Date | High-speed Industrial Printing | Industrial Coders | Laser Marking | QR Code | Data matrix codes | Barcode | CIJ | Laser Coders | TTO | Linx Authorized distributor in UAE | Coding machines UAE | Coding Machines Oman | Industrial Printers UAE & Oman