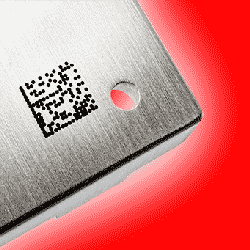

laser marking on metal

Inkjet coding and laser marking specialize in printing information such as serial numbers, production dates, and barcodes on metal. In fact, Laser marking machines can do printing and etching on the metal surface. Also, this technology does not require ink and other consumables for printing and marking on metal. In general, the use of laser printers on metal results in the best cost-effective output.

Inkjet Coder for Printing on Metal

Linx offers precise inkjet coding and marking solutions for printing on metal surfaces. As a result, this makes Linx printers suitable for extreme manufacturing conditions. Moreover, Linx coders meet coding requirements for the entire manufacturing industry. In addition, it offers right-angled printheads, which allow printing and coding in any orientation with various message-setting options. Additionally, we have the availability of special adhesive inks for components that require traceability. Linx specialized inks for returnable containers identically help with internal identification.

Inkjet Coding Solutions for Metal Industry

Metal sheets and cans require a specific type of coding and marking solution that is durable enough to withstand the industrial environment while maintaining its clarity and legibility. With inkjet technology, it’s possible to achieve crisp and high-resolution printing on both metal plates and cans for date coding and marking purposes. Condensed and fast-moving production lines can benefit from the fast and efficient inkjet printing process, ensuring minimal downtime or wasted materials. Beverage cans can benefit from inkjet coding as well as laser marking on metal cans. Providing consumers with a reliable and identifiable product. Inkjet coding on metal cans has never been more accessible thanks to the inkjet technology that offers a flexible and cost-effective coding solution.

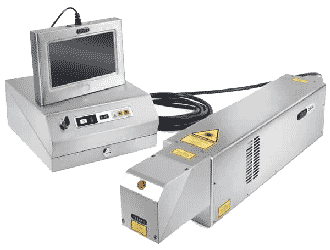

Relate Products – For Inkjet Coding & Laser Marking on Metal

Inkjet Coding on Metal Plates and Cans

- Choosing the correct ink:

Inkjet coding on metal surfaces requires specialized inks to resist environmental factors such as moisture, heat, and abrasion. Likewise, solvent-based or UV-curable inks falls preferable. - Legibility and durability:

The inkjet coding should produce clear, legible prints that remain visible throughout the product’s lifespan. The ink should also resist wear, ensuring the information remains accurate and legible. - Efficiency and speed:

Inkjet coding systems should be fast and efficient to keep up with high-volume production. This ensures accurate labeling without delaying the production process. - Integration with production line:

The inkjet coding system should integrate seamlessly with the existing production line, allowing for easy setup, operation, and maintenance.

Laser Marking on Metal Plates and Cans

- Choosing the suitable laser: Different lasers are available for marking on metal surfaces, including fiber and CO2 lasers. Fiber lasers for coding on metal because they create high-contrast, durable marks.

- Legibility and durability: Laser marking should produce clear, legible prints that remain visible throughout the product’s lifespan. The marks should also resist wear, ensuring the information remains accurate and legible.

- Efficiency and speed: Laser marking systems should be fast and efficient to keep up with high-volume production. This ensures accurate labeling without delaying the production process.

- Integration with production line:

The laser marking system should integrate seamlessly with the existing production line, allowing for easy setup, operation, and maintenance.

In conclusion, both inkjet coding and laser marking are suitable methods for printing information on metal plates and cans. Manufacturers can ensure that their products have precise information as per compliance and regulations. As a result, Linx coder will give you optimized efficiency and speed and integrate with the production line.