Printing on Paper and Cardboard Packages

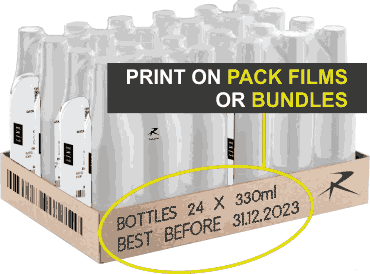

High-speed inkjet coding and laser marking have become the primary choice for printing on paper and cardboard. Continuous inkjet coders can produce variable text and codes using fast-drying inks in less than a second. This technology offers various pigmented options to achieve good contrast on colored packages. Moreover, laser coders specialize to scribe on paper and cards. Our extensive range of coding solutions offers both primary and secondary packaging options. The IJ series of large-character printers results best while printing large characters on cartons, boxes, trays, and more. End users can quickly achieve high-speed and efficient coding on paper and cardboard with our inkjet coding solutions.

Inkjet Coding on Paper & Card

In today’s fast-paced manufacturing industry, it is crucial to have efficient and timely coding systems in place. With inkjet coding on paper, businesses can meet this demand while staying at the forefront of their industry. It allows printing expiry dates and batch codes directly onto paper and cardboard boxes of primary packages. In fact, manufacturers can easily print on fast-moving cardboard boxes with continuous inkjet printers. Additionally, CIJ allows using a variety of ink types to suit both porous and non-porous materials. Companies can ensure accurate and precise coding on paper boxes with these printers. Moreover, these printers also use fast-drying ink to print on glossy paper and cardboard packages. Overall, ensuring the packaging and shipping of the product without delay. Inkjet coding results in the best solution for coding on porous paper packages.

Laser Marking on Cardboard

Laser marking on cardboard packages during manufacturing is an efficient and reliable way to ensure product identification and traceability. Linx Laser coder allows etching expiry dates and batch codes onto fast-moving packages on the production line. Laser marking is cost-effective because it eliminates the need for additional labels or stickers as well as ink. Furthermore, laser marking ensures a permanent and tamper-proof marking solution that will last the life of the product. With all these benefits, laser marking on cardboard packages has become a popular choice for manufacturers worldwide. Moreover, it overlaps the inkjet coding on paper for nonporous packaging.

Industrial laser etching on cardboard is a non-contact, efficient, and eco-friendly method. Furthermore, it can print expiry dates, QR codes, lot codes, and more directly on the product surface. It works by using a focused laser beam to create precise, high-contrast marks on the cardboard. Despite of highly intense laser beam, it does not cause damage or deformation to the cardboard.

Industrial laser marking on cardboard

- Choosing the appropriate laser:

CO2 laser for etching on paper and cardboard materials due to their ability to produce high-quality marks with minimal damage to the substrate. The wavelength of CO2 lasers suits well for absorbing energy from organic materials like cardboard, which results in efficient and clean marking. - Generating the design:

Specialized software to create design, text, or code (such as an expiry date, QR code, or lot code). The software thereafter forwards the digital design to the laser system controller. - Focusing the laser beam:

The laser system particularly focuses the beam onto the cardboard surface for etching. This usually happens through a series of lenses or mirrors. The focused laser beam has a very high energy density, which enables it to selectively remove or alter the top layer of the cardboard material. - Etching the cardboard:

As the laser beam moves across the cardboard surface, it vaporizes or ablates the top layer of the material, creating precise and high-contrast markings. The process does not involve any ink or chemicals, making it an environmentally friendly option.

Advantages of using laser etching on cardboard

Laser etching is suitable for various applications, including marking on boxes of tobacco, perfumes, cereals, and many other products.

- High precision and quality: Creates accurate, legible, and durable markings, even on small or intricate designs.

- Fast processing speeds: Suitable for high-speed production lines, ensuring efficient operations.

- Non-contact method: Laser etching printers do not physically touch the cardboard surface. Overall, it reduces the risk of damage or deformation to the packaging.

- Eco-friendly: Eliminates the need for inks, solvents, and other consumables, reducing waste and environmental impact.

In general, laser etching is an effective marking technique for manufacturers looking to code on nonporous products.

Laser marking on paper packaging has become popular due to its precision, versatility, and eco-friendly nature. Here are some of the standard applications of laser marking on paper packaging:

- Barcodes and QR codes:

In the first place, Laser coders can create high-resolution barcodes and QR codes directly on the paper packaging. Also, it allows tracking and inventory management of the finished product. - Expiration dates and batch numbers:

Laser marking can easily print expiration dates coupled with batch numbers on the packaging. In fact, ensuring accurate and legible data for consumers and manufacturers. - Logo:

Lasers marking printers can also mark logos and branding elements on paper packaging. Moreover, it enhances product presentation and brand recognition. - Product information:

Laser coders can print detailed product information, instructions, or warnings on paper packaging. In particular, it ensures clear communication with the end users. - Serialization and unique identification:

Lasers can create unique serial numbers or identification codes on paper packaging for security, anti-counterfeiting, and traceability purposes. - Warning and Usage Instruction:

Laser marking machines can directly mark warning signs and usage instructions on paper packaging. Indeed, adding an aesthetic appeal to the product.

Advantages of Laser marking on paper packaging

- Non-contact method: Lasers marking machines do not physically touch the product surface, reducing the risk of damage or deformation to the packaging.

- High precision and resolution: Lasers can create highly accurate and detailed markings, even on small or complex designs.

- Fast processing speeds: Laser marking is suitable for high-speed production lines, ensuring efficient operations.

- Eco-friendly: Laser marking eliminates the need for inks, solvents, and other consumables, reducing waste and environmental impact.

In summary, laser marking on paper packaging provides a versatile and eco-friendly solution for creating various types of markings, including barcodes, expiration dates, logos, product information, and decorative designs. This technology offers high precision, fast processing speeds, and reduced environmental impact, making it an attractive option for manufacturers and packaging companies.

Need guidance selecting the right laser solution for paper packaging? Talk to our experts now.