Reliable Global offers high-performance shrink wrapping machines engineered for a wide range of industries including cosmetics, perfumes, healthcare, and food products. Our versatile systems deliver compact, secure packaging that enhances product presentation while maximizing storage efficiency. Shrink wrapping not only creates a strong barrier against dust, moisture, and damage but also allows for custom-printed wrap to boost your brand visibility on shelves. With the ability to support unique packaging designs, reduce labor and material costs, and optimize space utilization, our shrink wrap machines are an ideal choice for businesses aiming to improve packaging quality and operational efficiency.

Heat Shrink Tunnel

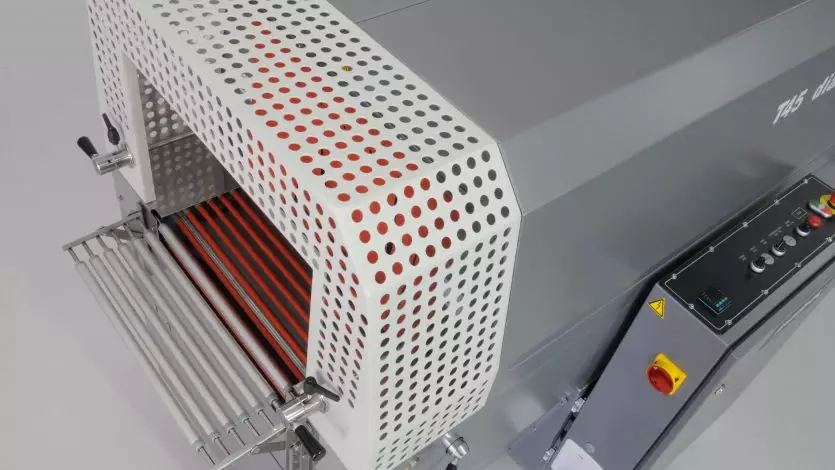

Heat shrink tunnels have become an indispensable technology for modern industries. Shrink tunnels stand out in terms of its efficiency and versatility. They are designed to create a tight, secure wrap around any item inside the shrink film. In addition to offering superior protection, Shrink tunnels are also ideal for improving the appearance of products and making them more visually appealing. These machines save companies time, reduce labor costs, and improve productivity. They can wrap anything, from electronics to food products, making them an essential investment for any company that wants to streamline its packaging process.

Automatic Heat Tunnel

Diamond Heat Machine

Heat shrink tunnels are typically located above or surrounding a conveyor belt section, facilitating automated travel through the tunnel. This design enables efficient and seamless logistical operations.

| Technical Data | standard heat shrink tunnel |

|---|---|

| Maximum Packaging Sizes | W: 350 x L: 450 x H: 120 mm |

| Sealer Opening | 160mm |

| Conveyor Speed | 30 mt/min (adjustable) |

| Cross Sealer Lenght | 580 x 440mm |

| Working Height | 860mm |

| Conveyor Belt Width | 400mm |

| Minimum Package Width | 50mm |

| Maximum Film Width | 650mm |

| Film Thickness (Minimum / Maximum) | 10 - 40 micron (1,6 mil) |

| Film Types | POF, PE, OPP, CPP, PP |

| Color | Grey Mixed + RAL7010 + RAL7015 |

| Maximum Roll Diameter | 300mm Standard (adjustable) |

| Installed Power | 50-60 Hz, 400 V, 6 Ampere, 3 Fase |

| Consumption (Maximum/Average) | 4kW / 3 kW |

| Dimensions (WxLxH) | 1240 x 2080 x 1890 mm |

| Palletized Size (WxLxH) | 1400 x 2270 x 1680 mm |

| Weight (Net/Gross) | 748 kg / 828 kg |

Explore our full catalog of shrink wrapping machines designed to meet diverse production needs and enhance your packaging efficiency. Whether you’re upgrading existing lines or starting new projects, our expert team is here to help you select the perfect solution. Contact us today to discuss your requirements and discover how our advanced machinery can drive your business forward.

Products listed: Forming Collar | Tray Sealing | Thermoforming | Pallet Wrapping | Horizontal Form Filling | Vertical Flow Wrapping | Shrink Wrapping | Protective Packaging | Filling & Capping | Print & Apply | Cable Conveying | Secondary Packaging

Heat Shrink Tunnel

Heat shrink tunnels have become an indispensable technology for modern industries. Shrink tunnels stand out in terms of its efficiency and versatility. They are designed to create a tight, secure wrap around any item inside the shrink film. In addition to offering superior protection, Shrink tunnels are also ideal for improving the appearance of products and making them more visually appealing. These machines save companies time, reduce labor costs, and improve productivity. They can wrap anything, from electronics to food products, making them an essential investment for any company that wants to streamline its packaging process.

Automatic Heat Tunnel

Diamond Heat Machine

Heat shrink tunnels are typically located above or surrounding a conveyor belt section, facilitating automated travel through the tunnel. This design enables efficient and seamless logistical operations.

| Technical Data | standard heat shrink tunnel |

|---|---|

| Maximum Packaging Sizes | W: 350 x L: 450 x H: 120 mm |

| Sealer Opening | 160mm |

| Conveyor Speed | 30 mt/min (adjustable) |

| Cross Sealer Lenght | 580 x 440mm |

| Working Height | 860mm |

| Conveyor Belt Width | 400mm |

| Minimum Package Width | 50mm |

| Maximum Film Width | 650mm |

| Film Thickness (Minimum / Maximum) | 10 – 40 micron (1,6 mil) |

| Film Types | POF, PE, OPP, CPP, PP |

| Color | Grey Mixed + RAL7010 + RAL7015 |

| Maximum Roll Diameter | 300mm Standard (adjustable) |

| Installed Power | 50-60 Hz, 400 V, 6 Ampere, 3 Fase |

| Consumption (Maximum/Average) | 4kW / 3 kW |

| Dimensions (WxLxH) | 1240 x 2080 x 1890 mm |

| Palletized Size (WxLxH) | 1400 x 2270 x 1680 mm |

| Weight (Net/Gross) | 748 kg / 828 kg |

Heat Shrink Tunnel

Heat shrink tunnels have become an indispensable technology for modern industries. Shrink tunnels stand out in terms of its efficiency and versatility. They are designed to create a tight, secure wrap around any item inside the shrink film. In addition to offering superior protection, Shrink tunnels are also ideal for improving the appearance of products and making them more visually appealing. These machines save companies time, reduce labor costs, and improve productivity. They can wrap anything, from electronics to food products, making them an essential investment for any company that wants to streamline its packaging process.

Automatic Heat Tunnel

Diamond Heat Machine

Heat shrink tunnels are typically located above or surrounding a conveyor belt section, facilitating automated travel through the tunnel. This design enables efficient and seamless logistical operations.

| Technical Data | standard heat shrink tunnel |

|---|---|

| Maximum Packaging Sizes | W: 350 x L: 450 x H: 120 mm |

| Sealer Opening | 160mm |

| Conveyor Speed | 30 mt/min (adjustable) |

| Cross Sealer Lenght | 580 x 440mm |

| Working Height | 860mm |

| Conveyor Belt Width | 400mm |

| Minimum Package Width | 50mm |

| Maximum Film Width | 650mm |

| Film Thickness (Minimum / Maximum) | 10 – 40 micron (1,6 mil) |

| Film Types | POF, PE, OPP, CPP, PP |

| Color | Grey Mixed + RAL7010 + RAL7015 |

| Maximum Roll Diameter | 300mm Standard (adjustable) |

| Installed Power | 50-60 Hz, 400 V, 6 Ampere, 3 Fase |

| Consumption (Maximum/Average) | 4kW / 3 kW |

| Dimensions (WxLxH) | 1240 x 2080 x 1890 mm |

| Palletized Size (WxLxH) | 1400 x 2270 x 1680 mm |

| Weight (Net/Gross) | 748 kg / 828 kg |