Filling, Capping and Labelling

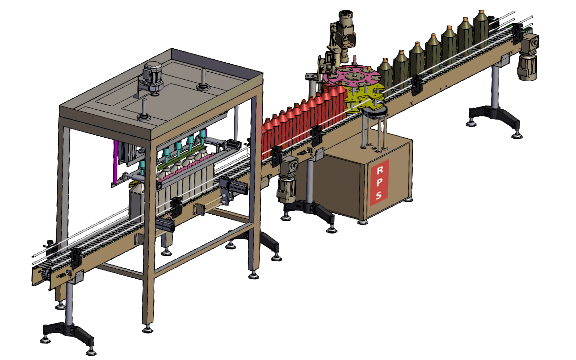

For all types of powder, liquid and semi-liquid, viscous products, bottles & jars of different shapes and sizes, we can offer filling & capping machines.

A wide range of labelling machines and solutions can be used for various types of product and labels. We supply standardized and tailor-made solutions for the food, chemical, perfume and cosmetic industries.

Filling units: Dosing units are suitable for the volumetric, pneumatic and electronic filling of powder, dense and semi-dense products. Our solutions are suitable to fill creams, liquids, powders, aggressive products etc.

Capping Units: Our capping systems are appropriate for each type of closure: screw caps snap or twist off. We also have tailored pick and place systems for automatic cap positioning.

Labelling Units: Application equipment can be top, bottom, front/back, wrap-around, and print & apply, security seal and others.

Filling units

Powder Filling Machine

The PMR powder filling machines find their applications in a wide range of industries like chemical, construction, cosmetic, pharmaceutical, food and other technologies. We offer table top filling solutions as well as automatic filling machines.

Usually equipped with

- Conveyor belts with speed control

- Dosing units with vertical cochlea to fill powder

- Labelling machine

- Capping unit (screw/pressure cap)

- Automatic cap feeder

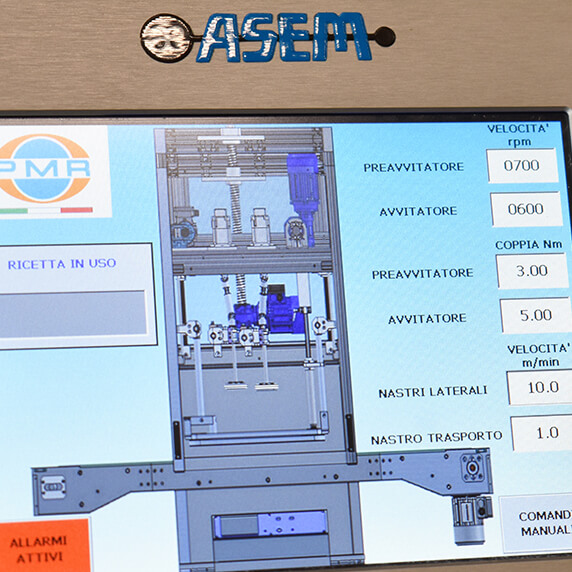

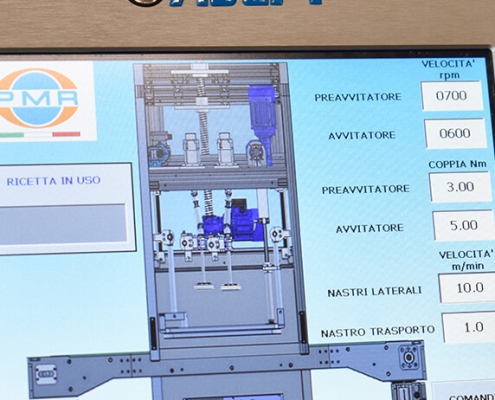

- Touch screen control can help customize parameters and settings like dosing and application of label.

Liquid Filling Machine

Suitable for a wide range of containers of different capacities and sizes, we have tabletop, semi-automatic and automatic solution liquid filling solutions. Obtain a tailored solution to meet your production needs, with both pneumatic and electronic options. Automatic liquid dosing units can be equipped with more than 4 dosing groups. We can provide a solution based on the characteristics of your product and your requirements.

Tabletop solutions

- Table Top Dosing Unit Mod. PMR 1 – Pneumatic

- Table Top Dosatron – Electronic

Semi-Automatic Solutions

Automatic Solutions

- Automatic Rotary Monoblock

- PMR Rotoblock

- Filling And Capping Line

- Triblock

Filling machine for creams and similar formulae

Find a wide range of dosing units for filling semi-dense products such as juices, essences, shampoo, oils and creams. Electronic, semi-automatic and pneumatic dosing units are available and be customised to meet the characteristics of your substrate/ product.

Our filling machines have various options such as heated hopper, nozzles, product feeding pumps and can be both linear and rotary to accommodate containers of various sizes. Our automatic filling machines can ve equipped with 4+ pneumatic dosing groups or flowmeters if required.

Tabletop solutions

- Table Top Dosing Unit Mod. PMR 1 – Pneumatic

- Table Top Dosatron – Electronic

Semi-Automatic Solutions

Automatic Solutions

- Automatic Rotary Monoblock

- PMR Rotoblock

- Filling And Capping Line

- Triblock

Fill aggressive products with automatic and semi-automatic filling machines

The PMR filling machines for filling aggressive products are suitable to fill dense, liquid cream products in rigid containers.

These semi-automatic and automatic, volumetric weighing dosing machines can be easily operated using a touch panel. This user-intuitive touch panel can be used to set production filling parameters like dosing tolerance, production speed and doing range adjustment.

Filling solutions

- Filling And Capping Monoblock

- Semi-Automatic Weighing Dosing Unit

Filling machine for nail polish and special products

To fill perfumes, solvents and products like nail paints we have specialized PMR level dosing machines.

The product reaches the ampoule through a tank, and the dosing time is monitored and controlled to attain optimal production speed. A complete system is composed by combining this durable dosing machine with a rotary table for positioning and a capping station.

Filling solutions

- Filling And Capping Monoblock

- Semi-Automatic Weighing Dosing Unit

Capping units

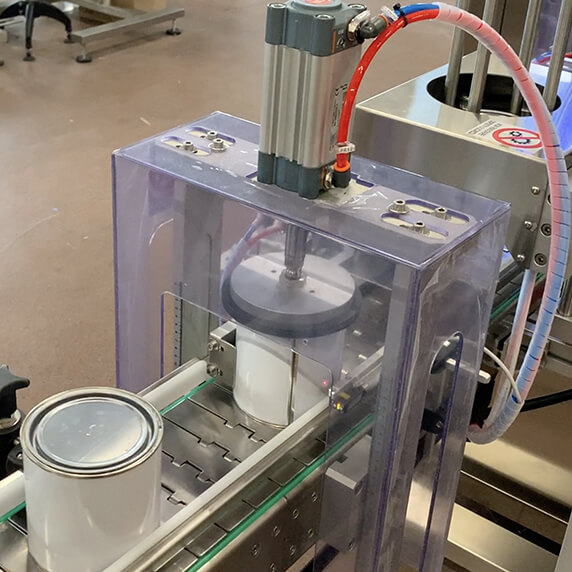

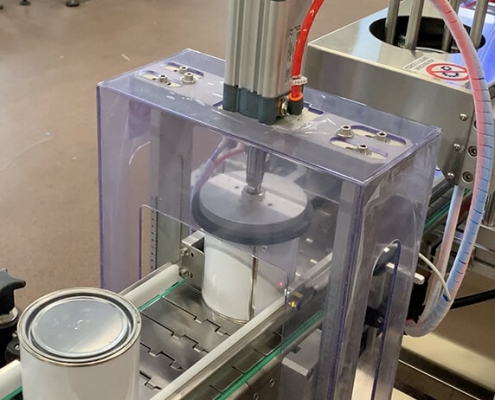

Screw Capping System

Depending on customer needs and line speed we have tabletop, semi-automatic and high-speed automatic capping systems. Suitable for square, round/ shaped containers of materials both glass and plastic our capping systems can be catered to your production needs.

The manual tabletop solutions are equipped with a pedal/ start button for operation. The semi-automatic and automatic solutions cater to high speeds.

Closure pressure regulation, automatic vibrating cap feeders, adjustable heights, and compatibility with different materials are just some of the features of our capping solutions.

Tabletop solutions

Semi-Automatic Solutions

Automatic Solutions

Twist-off Capping System

Reliable packaging systems provide PMR Twist-off closure/capping solutions that are suitable for capping various cap and product formats. Adjustments for both vertical pressure and container blocks help tailor and improve your production capabilities.

The format change is easy and intuitive and makes the capping system compact, user-friendly and easy to use.

Automatic twist off capping solutions guarantee a constant vacuum level, have high corrosion resistance and are easy to operate. A quick format change and easy format adjustment make our capping system an ideal solution.

Tabletop solutions

Automatic Solutions

Pressure Capping System

Equipped with pressure adjustment and easy format change functionality our pressure capping systems can be customised to your requirements. Close square, round/shaped containers, made of both glass and plastic.

In addition to the small size and easy to use tabletop capping systems for small scale production, there is a range of semi-automatic and automatic systems. A range of products can be capped with our linear and rotary capping systems and user-friendly functionality like easy height adjustment.

Tabletop solutions

Semi-Automatic Solutions

Automatic Solutions

Trigger Capping System

The PMR trigger capping system is suitable for various types of triggers at high speeds, this enables automatic capping even during high production. Equipped with a conveyor belt, the linear roller capping machine is ideal for items like spray pumps.

The rotation speed and torque for each product are obtained by a brushless motor through a rubber disc and provide a production rate of around 5000 pcs per hour.

The settings can be stored in the machine and easily recalled when required through a touch screen.

Capping System For Trigger Closures