Weighbridge for construction industry

Using a weighbridge is equally essential to ensure safety in transportation on a construction site. Not only does it help to meter out loads and distribute them evenly, but it also helps prevent vehicle overloading. Instead, overloading can result in swift wear and tear of parts, leading to higher fuel consumption, which can become a significant cost for businesses to bear. Indeed reliable, accurate, and rugged weighbridge systems are crucial for the construction industry. Truck scales and weighbridges are especially designed to withstand harsh environments. Also, we offer various surface and pit mount options for multiple applications. Initiatives such as crushers and asphalt plants need these scales on a daily basis. Moreover, with these heavy-duty industrial weighing scales, the construction industry can ensure they accurately and efficiently measure the materials.

Truck Scales and Construction Sites

As can be seen in the fast-paced and constantly evolving construction industry, the weighing scale plays an equally important role. In fact, relying on the right tools and systems is crucial to meet high efficiency and performance standards. Indeed a reliable weighing system is one of the essential tools that construction companies need to ensure optimal results. Specifically, employing truck scales at construction sites is a must-have. These scales can accurately weigh materials, such as heavy machinery, equipment, and construction materials, resulting in precise invoicing and output monitoring. Moreover, these scales help prevent accidental overloads and safety hazards, ensuring the site remains a safe and productive area for workers. Overall, incorporating a dependable weighing system, like truck scales, is a vital consideration for any construction industry stakeholder looking to stay ahead of the competition.

The accuracy of a weighing system can be affected by several environmental factors:

When it comes to accurately weighing materials on a construction site weighbridge, it’s essential to be aware of the various environmental factors that can affect the reliability of the readings. Overall, wind loading, vibration, and dirt caused by air conditioners and ducts can have an impact. Shock loading from sudden heavy loads can potentially damage the weighbridge and load cells, while electrical interference can interfere with the electrical systems of the controller. Moreover, understanding these environmental factors makes it possible to take preventative measures and ensure that the weighing system remains as accurate as possible, thereby contributing to a successful construction project.

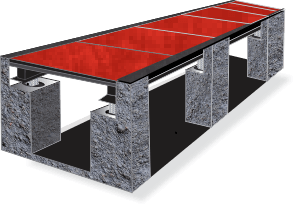

Weighbridge for Construction Industry Dimensions and Capacities.

| Dimensions | Capacity | Load Cells |

|---|---|---|

| 6 meter x 3 meter | 30 Ton or 30000 kg to 35 Ton or 35000 kg | 4 |

| 12 meter x 3 meter | 50 Ton or 50000 kg to 60 Ton or 60000 kg | 6 |

| 18 meter x 3 meter | 80 Ton or 80000 kg to 120 Ton or 120000 kg | 8 |

| 24 meter x 3 meter | 120 Ton or 120000 kg to 150 Ton or 150000 kg | 10 |

| 21 meter x 3 meter | 120 Ton or 120000 kg to 150 Ton or 150000 kg | 10 |

| 2 meter x 2 meter | 5 Ton or 5000 kg | 4 |

| 2 meter x 1.5 meter | 5 Ton to 5000 kg | 4 |

| 1.5 meter x 1.5 meter | 3 Ton or 3000 kg to 5 Ton or 5000 kg | 4 |

| 1.2 meter x 1.2 meter | 1 Ton or 1000 kg to 2 Ton or 2000 kg | 4 |

| 1 meter x 1 meter | 1 Ton or 1000 kg | 4 |

Importance of Truck Scale and Weighbridge in Construction Industry

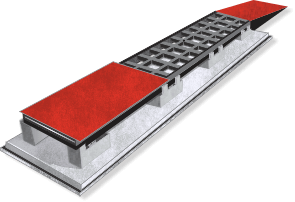

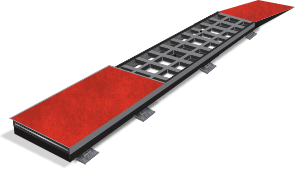

In short, a reliable and accurate solution is required to weigh trucks on construction sites. This is where truck scales, also known as weighbridges, come into play. Indeed, they are designed to handle various weights and material types in different weather conditions, ensuring that the trucks carry the correct load for maximum efficiency. In addition to traditional fixed weighbridges, portable truck scales are a mobile alternative that provides the same level of accuracy. Also, the lightweight and easy-to-assemble and dismantle quality makes them a convenient option for construction sites. Moreover, these portable truck scales enable fabrication as per customer requirements, making them a reliable choice for accurate weight measurement.

Why are Weighing Scales so crucial for the Construction industry?

Weighing scales play a critical role in the construction industry as they allow incoming and outgoing material accuracy at the same time. Contractors, subcontractors, owners, and engineers accurately measure the weight of materials, supplies, and vehicles similarly. Correspondingly, this helps them know what products will be needed for the duration of any given project. Moreover, weighing scales enables contractors to easily calculate soil compaction rates and perform quality control checks on their materials.

Weight measurements also help ensure the safety of employees and equipment during transportation and delivery operations. Having an accurate understanding of each shipment’s weight before loading up trucks or containers with material enables personnel to account for proper safe working load limits to prevent potential accidents due to overloads.

The scales specialize in larger construction companies with multiple sites operating simultaneously. Setting up weighbridges gives them one centralized location where all vehicle weights can be checked before entering or exiting the property so that managers have quick access points when it comes time for billing purposes since invoice amounts will depend upon properly weighed shipments according to contractual agreements with suppliers.

In conclusion, weighing scales are significant in today’s modern construction industry. These machines allow members within this field to efficiently manage material deliveries throughout large-scale projects while ensuring personnel safety at every step!