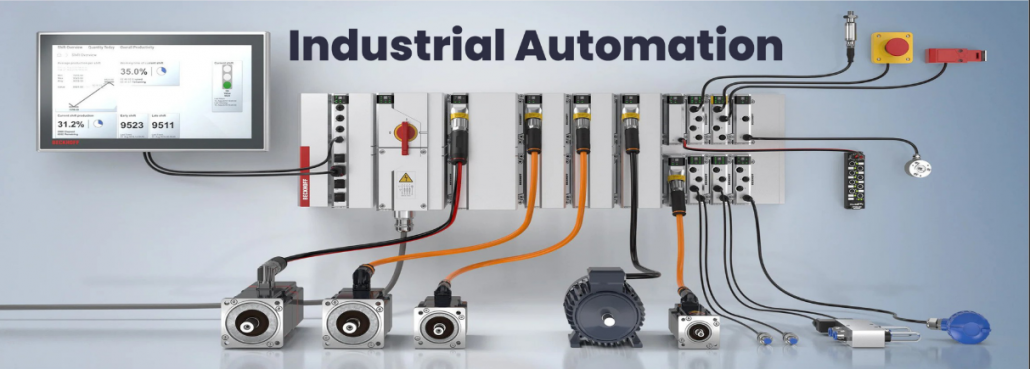

Automation & Software Solutions

Boost Production Line Efficiency & Quality with Automation & Software Solutions Featuring Smart Automation and Vision Inspection Systems

Automation and Software Solutions at Reliable Industrial Equipment Co. LLC are designed to improve your production line with cutting-edge technology. Our intelligent systems integrate smart scanning, labeling, sorting, and conveyor control to boost efficiency and accuracy. With AI-powered vision inspection, we provide real time quality checks that detect defects, verify printed codes, and ensure compliance—all with minimal human intervention. By combining automation with precise vision technology, we help manufacturers increase productivity, reduce errors, and maintain high quality standards seamlessly.

Automatic Scanning Machines | Automation & Software Solutions

As part of our Automation & Software Solutions, we offer high-speed inline text and code scanning with easy integration. These machines support both manual and automatic modes, making them suitable for different setups. They scan text and 1D/2D barcodes in real time and can be connected to conveyors, pick and place systems, or rejection systems. Moreover, they are designed for fast operations with low maintenance, helping reduce errors and minimize rework.

Key Features:

- High-speed 1D/2D code scanning algorithm

- Vibration-free conveyor and rejection bin

- Integrated label application logic to reduce wastage

- Reflection-free illumination for glossy/shrink-wrapped surfaces

- Automatic traffic management to prevent jamming

- Software-controlled camera synchronization

Multi-Scanning Machine | Automation & Software Solutions

Top-Side Code Reading with No Manual Adjustments

Designed for operations requiring multiple top-side code scans, this machine reads pre-printed 1D/2D text and codes at various box heights. Ideal for manual or semi-automatic packing lines.

Key Features:

- Auto and manual triggering options

- High-resolution camera with robust decoding algorithm

- Simultaneous scanning of multiple codes

- Custom illumination for reflective surfaces

- Adjustable guides for various box sizes

- Designed to improve production uptime and speed

Manual Scanning Machine | Automation & Software Solutions

Simple Code Verification Using Existing Camera Infrastructure

The Manual Scanning Machine is a camera and scanner based system used for verifying text and codes against databases. Ideal for operations requiring selective scanning or occasional inspection.

Key Features:

- Easy integration with existing systems

- PLC-based triggering with an intuitive user interface

- Wi-Fi handheld scanner for manual input

- Designed for tough industrial environments

Product Diverting Machine | Rejection Systems | Automation & Software Solutions

Smart Scanning with Sorting and Labelling Functionality

As part of our Automation & Software Solutions, this system combines scanning, sorting, and labeling to handle high-volume operations efficiently. After scanning the codes, products are automatically diverted—either accepted or rejected, and then labeled accordingly.

Key Features:

- Simultaneous multi camera scanning

- Label application with camera or scanner systems for verification

- Adjustable speed conveyor with traffic control

- Illumination and optics for reflective packaging

- Quick product changeovers

- Designed to improve throughput and reduce manual intervention

Conveyor Control Systems | Automation & Software Solutions

Efficient Control Panel for Conveyor & Automation Integration

Reliable’s custom built control systems are designed to integrate with conveyor setups and support other automation modules.

Key Features:

- PLC-based logic control

- Multiple I/O ports for signal integration

- Durable design for difficult factory conditions

Vision Inspection Systems

OCR Code Verification | Automation & Software Solutions

Optical Character Recognition for Printed Code Validation

As part of our Automation & Software Solutions, we use advanced OCR technology to verify alphanumeric text on packaging, including expiry dates, batch numbers, and lot codes. We offer customized systems that ensure consistent quality and help meet regulatory standards, especially for industries like pharmaceuticals, food, and cosmetics.

Key Features:

- High-resolution smart camera for accurate character recognition

- Real-time validation against preloaded or dynamic databases

- Compatible with inkjet, thermal, and laser printed codes

- Integrated with rejection system for non compliant items Compatible with inkjet, thermal, and laser printed codes

- Minimal operator input

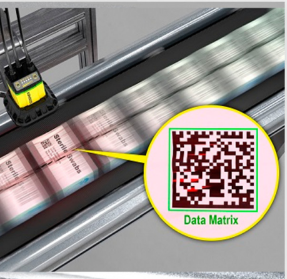

Barcode Reading | Automation & Software Solutions

1D/2D Barcode Scanning for Product Tracking and Verification

Reliable’s barcode reading system scans and confirms 1D and 2D codes (e.g., QR, DataMatrix) on fast moving production lines. It’s enhanced for a variety of surfaces, including glossy, curved, or shrink wrapped products.

Key Features:

- Multi-angle and multi surface scanning support

- High-speed decoding with error detection

- Compatible with GS1 and custom formats

- Seamless integration with conveyors and sorting stations

- LED illumination for glare reduction on reflective surfaces

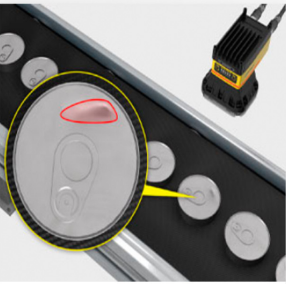

Visual Inspection for Surface Flaws and Packaging Errors | Automation & Software Solutions

This solution detects defects such as scratches, dents, wrongly aligned labels, missing prints, and packaging damage. It helps prevent damaged products from reaching end users and maintains brand quality. These systems are widely used in the Cosmetics, Food & Beverage industries.

Key Features:

- AI-based image processing for accurate defect sorting

- Detects print smears, color variations, wrongly aligned labels, and more

- High-speed inspection with frame by frame analysis

- Compatible with top, bottom, and side view camera setups

- Real-time alerts and auto refusal function